Ultralow-temperature micro-abrasive air jet machining device for polymer micromachining

A processing device and a technology of polymer materials, which are applied in the direction of abrasive feeding devices, abrasive jet machine tools, abrasives, etc., can solve the problems of poor processing stability, difficult control of processing quality, embedding of abrasives, etc., and achieve high processing efficiency and improved Material removal rate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the solutions similar to this case made by other persons in the field are all within the protection scope of the present invention.

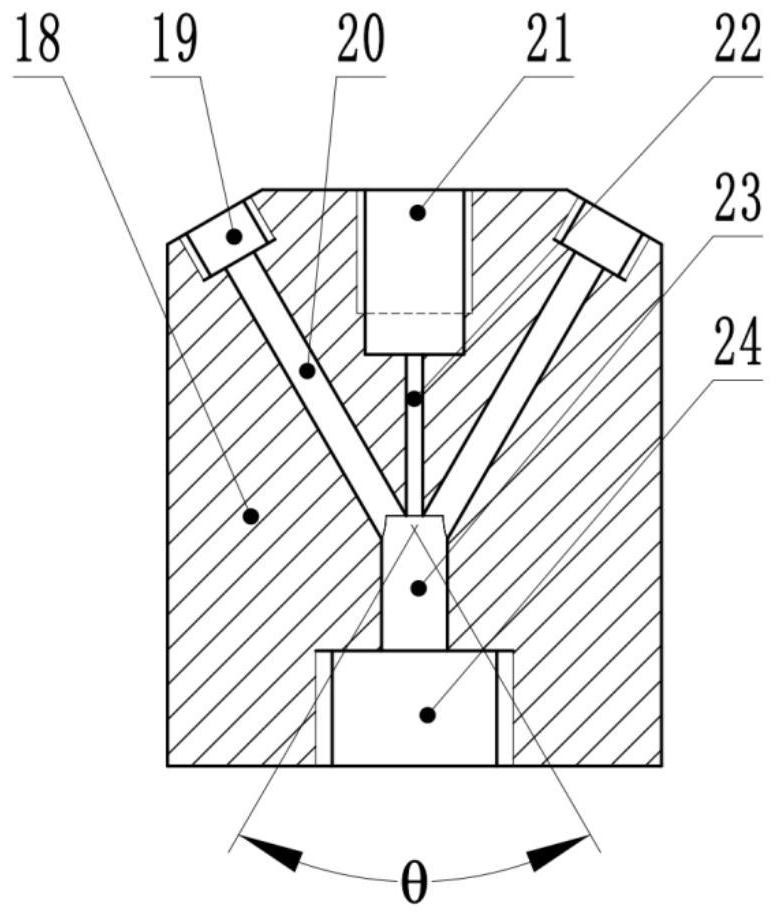

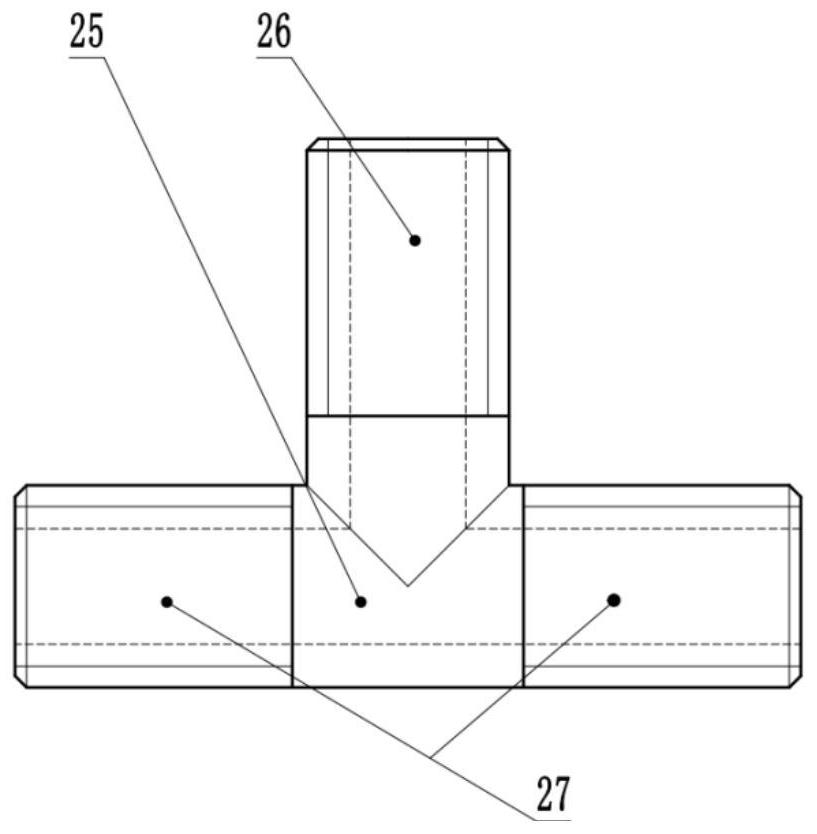

[0027] Such as Figure 1-4 shown.

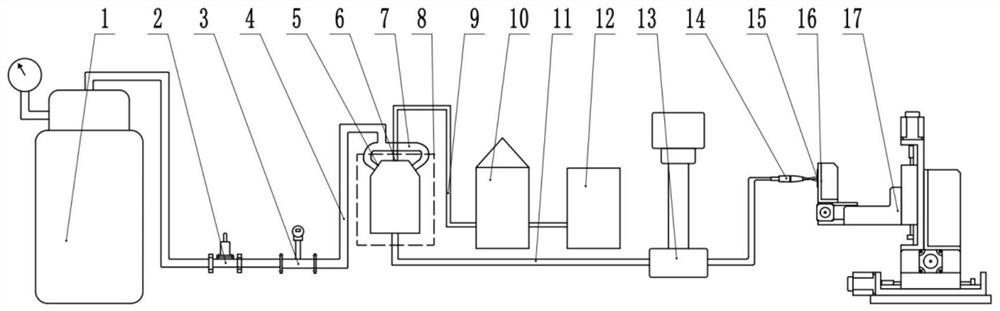

[0028] An ultra-low temperature micro-abrasive gas jet processing device for micro-processing of polymer materials, which includes: a liquid nitrogen adjustment system, an air micro-abrasive two-phase flow generator, a liquid nitrogen micro-abrasive mixing system and a processing system, such as figure 1shown. The liquid nitrogen regulating system includes a self-pressurized liquid nitrogen tank 1, a pressure reducing valve 2 and a liquid nitrogen flowmeter 3, and the three are connected through the first ultra-low temperature insulation pipe 4; Outflow, through the pressure-stabilizing adjustment of the pressure reducing valve 2 and the flow adjustment of the liquid nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com