Preparation method and application of low-activity MDI-50 product

A MDI-50, low-activity technology, applied in adhesive types, polyurea/polyurethane adhesives, organic chemistry, etc., can solve the problems affecting the production process of laminating adhesive, high activity, low impurity content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

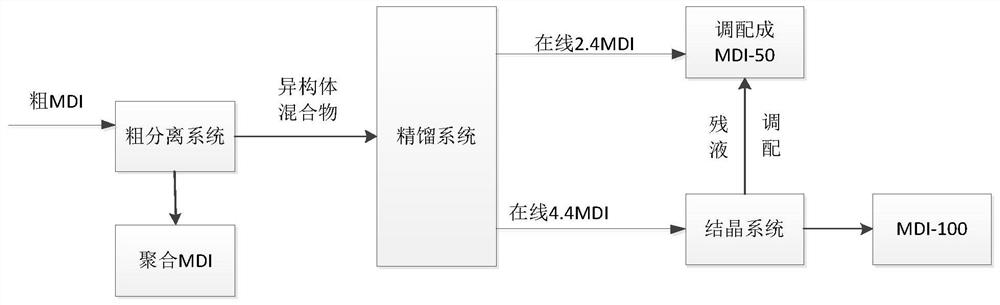

Image

Examples

Embodiment 1

[0036]The crude MDI that will contain 60wt% bicyclic, 10wt% tricyclic, 10wt% tetracyclic, 20wt% pentacyclic and mixtures of five or more rings is introduced into the vacuum separation tower at a bottom temperature of 215°C and a tower top temperature of 90°C. Separation under the process condition of tower top pressure 0.4kpa, obtain diphenylmethane diisocyanate mixture A1 and polymeric MDI, the 2,2-MDI that will obtain from the separation tower, the 2,4-MDI of 10wt%, The diphenylmethane diisocyanate mixture A1 of 88wt% 4,4-MDI is introduced into the rectification tower, and various parameters are adjusted through the tower temperature, extraction ratio, etc., wherein the temperature of the rectification tower bottom is controlled at 210 ° C, and the online 4 , the temperature of the 4-MDI extraction section is 208°C, and the online 4,4-MDI extraction ratio is based on the weight of the isocyanate mixture fed to the rectification tower to control the mass ratio at 80%, to obtai...

Embodiment 2

[0038] The crude MDI that will contain 63wt% bicyclic, 12wt% tricyclic, 8wt% tetracyclic, 17wt% pentacyclic and more than five rings is introduced into the vacuum separation column at a bottom temperature of 215°C and a tower top temperature of 90°C. Separation under the process condition of tower top pressure 0.4kpa, obtain diphenylmethane diisocyanate mixture A2 and polymerized MDI, the 2,2-MDI that will obtain from separation tower, the 2,4-MDI of 11wt% The diphenylmethane diisocyanate mixture A2 of 86.7wt% 4,4-MDI is introduced into the rectification tower, and various parameters are adjusted by tower temperature, recovery ratio, etc., wherein the temperature of the rectification tower bottom is controlled at 209°C, The temperature of the online 4,4-MDI extraction section is 207.8°C, the online 4,4-MDI extraction ratio is based on the weight of the isocyanate mixture fed to the rectification tower to control the mass ratio at 78%, and 2,2-diphenylmethane is obtained The di...

Embodiment 3

[0040] The crude MDI that will contain 60wt% of two rings, 10wt% of three rings, 10wt% of four rings, 20wt% of five rings and mixtures above five rings is introduced into the vacuum separation tower at a temperature of 213°C at the bottom of the tower, and a temperature of 89°C at the top of the tower. Separation under the process condition of tower top pressure 0.4kpa, obtain diphenylmethane diisocyanate mixture A3 and polymerized MDI, the 2,2-MDI that will obtain from the separation tower, the 2,4-MDI that contains 10.3wt% MDI, the diphenylmethane diisocyanate mixture A3 of 87.2wt% 4,4-MDI is introduced into the rectification tower, and various parameters are adjusted by tower temperature, extraction ratio, etc., wherein the temperature of the rectification tower bottom is controlled at 208°C , the temperature of the online 4,4-MDI extraction section is 207°C, the mass ratio of the online 4,4-MDI extraction is 78%, and the weight of the isocyanate mixture fed to the rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com