Antibacterial and antiviral natural detergent and preparation method thereof

A detergent and anti-virus technology, applied in antibacterial and anti-virus natural detergent and its preparation field, can solve the problems of unsatisfactory pass rate and poor antibacterial effect, and achieve low pollution and easy self-degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

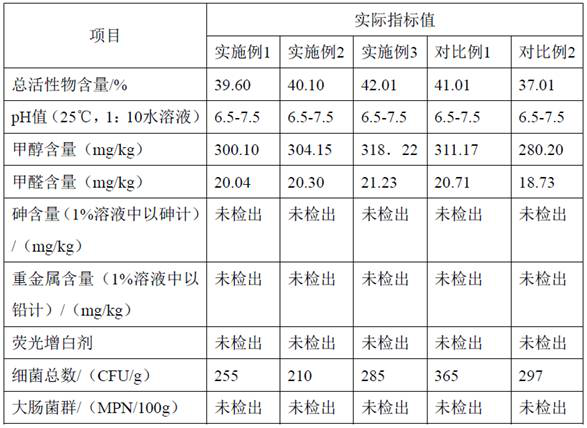

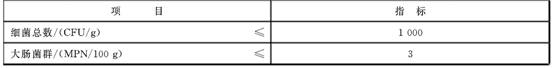

Examples

Embodiment 1

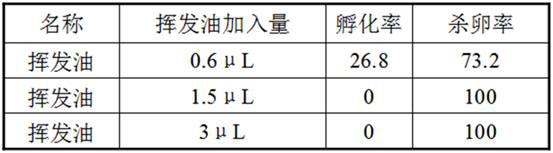

[0026] 1. Extraction of active ingredients

[0027] (1) Extraction of the volatile oil of Azalea

[0028] Collect the dried whole herb of Lemongrass, remove the dust, wash it, dry it in the shade, chop it (less than 2cm), weigh 5 kg, add 8 times the amount of water to soak for 1 hour, microwave solid-liquid phase extraction for 0.5 hour, the obtained volatile oil-water emulsion, Add NaCl to saturation, stir and let it stand for 24 h, add diethyl ether to extract 3 times, separate the oil layer, and dry it with anhydrous sodium sulfate to obtain a light yellow-green transparent oily liquid with a special smell. Seal the volatile oil and store it at 4°C. For testing.

[0029] (2) Extraction of saponins

[0030] Extraction of saponin in Camellia oleifera: Take 1 kg of pulverized Camellia oleifera seed cake, add 60% ethanol to extract at 80°C for 2 h, filter, concentrate, add organic decolorizer, pass through macroporous adsorption resin, and elute with 85% ethanol , concentrat...

Embodiment 2

[0035] 1. Extraction of active ingredients

[0036] (1) Extraction of the volatile oil of Azalea

[0037] Collect the dried whole herb of Lemongrass, remove dust, wash it, dry it in the shade, chop it (less than 3cm) and weigh 5 kg, add 8 times the amount of water to soak for 1.5 hours, microwave solid-liquid phase extraction for 1 hour, the obtained volatile oil-water emulsion, Add NaCl to saturation, stir and let it stand for 24 h, add diethyl ether to extract 3 times, separate the oil layer, and dry it with anhydrous sodium sulfate to obtain a light yellow-green transparent oily liquid with a special smell. Seal the volatile oil and store it at 4°C. For testing.

[0038] (2) Extraction of saponins

[0039] Extraction of saponin in Camellia oleifera: Take 1 kg of pulverized Camellia oleifera seed cake, add 60% ethanol to extract at 80°C for 2.5 h, filter, concentrate, add organic decolorizer, pass through macroporous adsorption resin, and elute with 85% ethanol , concentr...

Embodiment 3

[0044] 1. Extraction of active ingredients

[0045] (1) Extraction of the volatile oil of Azalea

[0046] Collect the dried whole herb of Lemongrass, remove the dust, wash it, dry it in the shade, chop it (less than 2cm), weigh 5 kg, add 8 times the amount of water to soak for 1 hour, microwave solid-liquid phase extraction for 0.5 hour, the obtained volatile oil-water emulsion, Add NaCl to saturation, stir and let it stand for 24 h, add diethyl ether to extract 3 times, separate the oil layer, and dry it with anhydrous sodium sulfate to obtain a light yellow-green transparent oily liquid with a special smell. Seal the volatile oil and store it at 4°C. For testing.

[0047] (2) Extraction of saponins

[0048]Extraction of saponin in Camellia oleifera: Take 1 kg of pulverized Camellia oleifera seed cake, add 60% ethanol to extract at 80°C for 3 h, filter, concentrate, add organic decolorizer, pass through macroporous adsorption resin, and elute with 85% ethanol , concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com