A preparation method of multi-scale high-strength high-entropy alloy material for corrosive environment

A high-entropy alloy and corrosive environment technology, applied in the field of metal composite materials, can solve the problems of long period of high-entropy alloy powder and reduce the corrosion resistance of high-entropy alloy, so as to achieve the effect of short preparation period, improved mechanical strength, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

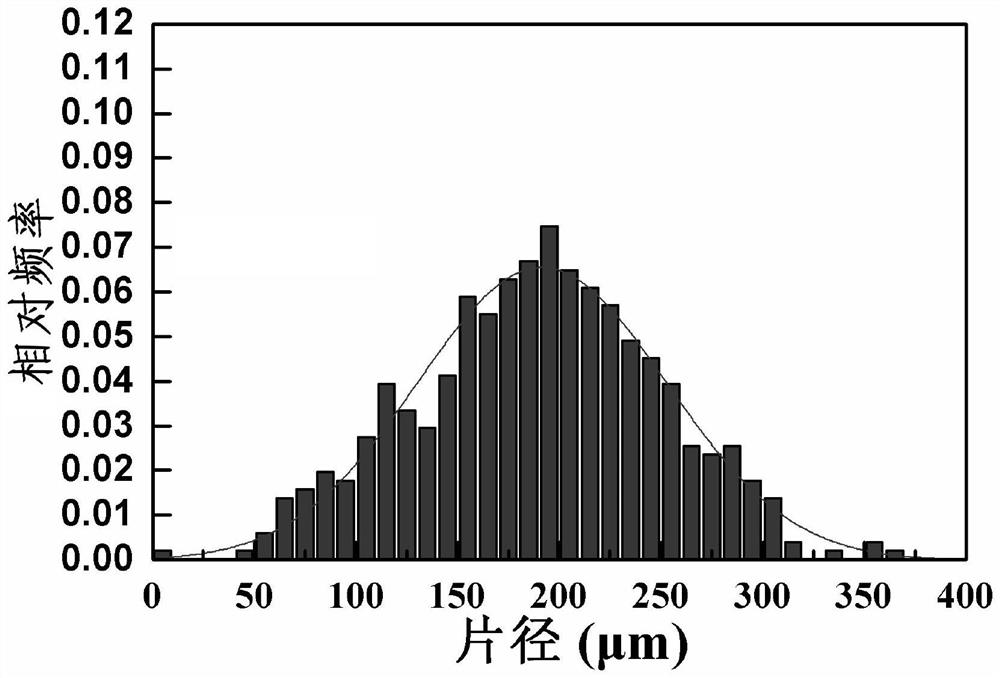

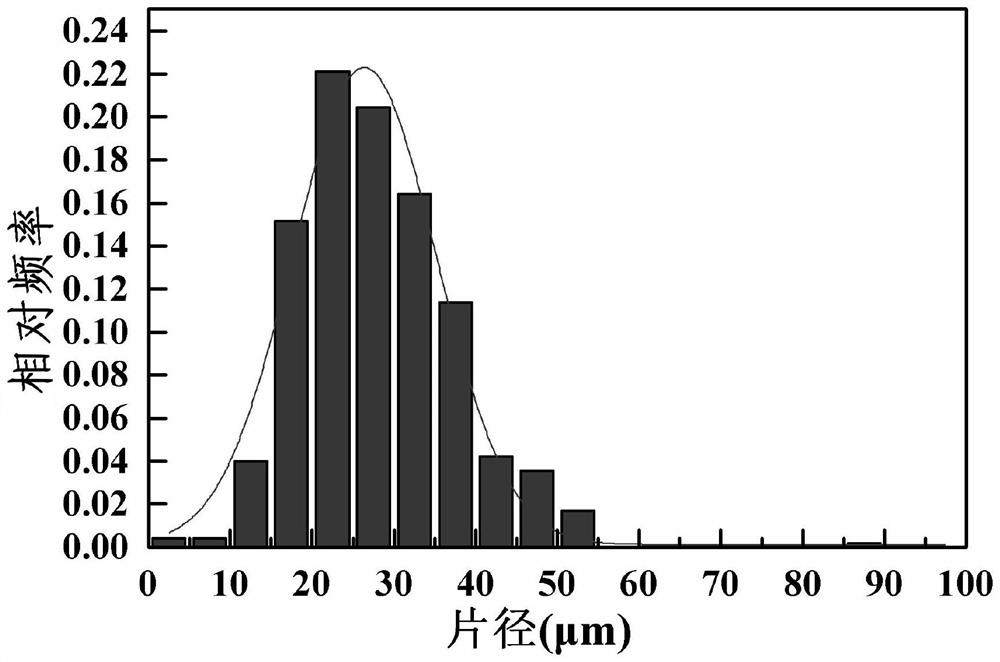

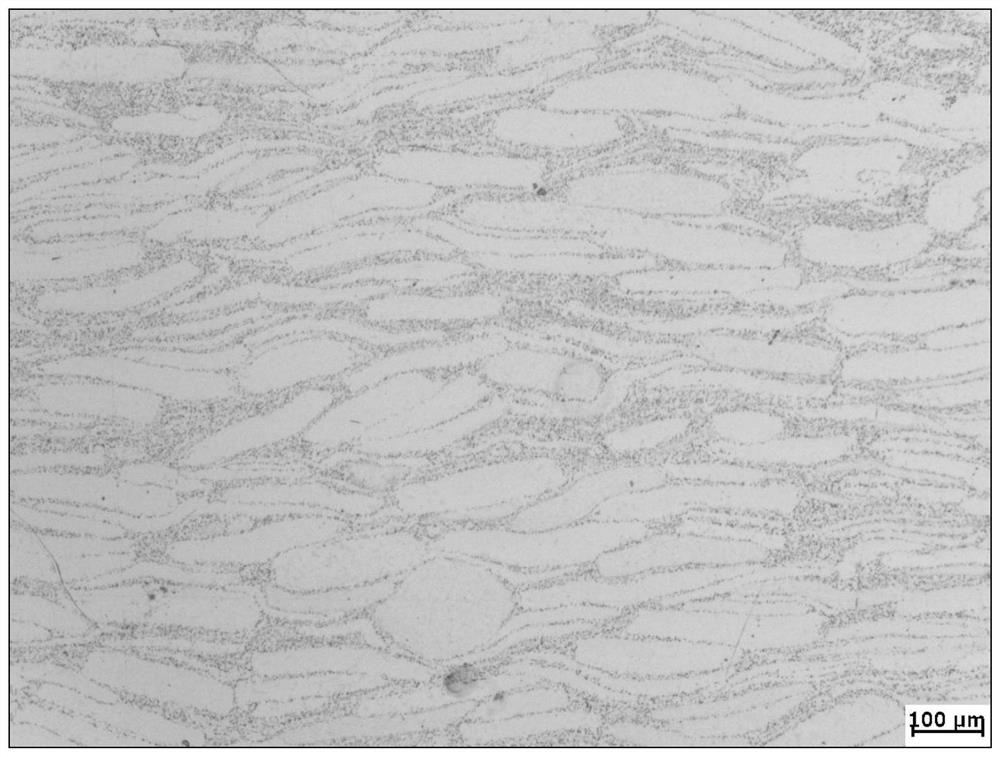

[0028] Step 1: Carry out ball milling on the spherical high-entropy alloy powders respectively and then package them to obtain multi-scale high-entropy alloy powder A and multi-scale high-entropy alloy powder B; the ball milling process for obtaining the multi-scale high-entropy alloy powder A is: The stainless steel balls with a mass ratio of 25:1 and the CoCrFeNiCu high-entropy alloy powder with a particle size of 200 mesh prepared by gas atomization are put into the stainless steel ball mill tank of the liquid nitrogen type low-temperature planetary ball mill, and then the stainless steel ball mill tank is filled with After argon, ball milling for 120min under the condition of rotating speed of 450r / min, multiscale high-entropy alloy powder A is obtained in a stainless steel ball mill tank; the ball milling process for obtaining the multiscale high-entropy alloy powder B is as follows: the mass ratio is 25:1 200-mesh Co...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] Step 1: Carry out ball milling on the spherical high-entropy alloy powders respectively and then package them to obtain multi-scale high-entropy alloy powder A and multi-scale high-entropy alloy powder B; the ball milling process for obtaining the multi-scale high-entropy alloy powder A is: The stainless steel balls with a mass ratio of 25:1 and the CoCrFeNiCu high-entropy alloy powder with a particle size of 200 mesh prepared by gas atomization are put into the stainless steel ball mill tank of the liquid nitrogen type low-temperature planetary ball mill, and then the stainless steel ball mill tank is filled with After argon, ball milling for 120min under the condition of rotating speed of 450r / min, multiscale high-entropy alloy powder A is obtained in a stainless steel ball mill tank; the ball milling process for obtaining the multiscale high-entropy alloy powder B is as follows: the mass ratio is 25:1 200-mesh Co...

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] Step 1: Carry out ball milling on the spherical high-entropy alloy powders respectively and then package them to obtain multi-scale high-entropy alloy powder A and multi-scale high-entropy alloy powder B; the ball milling process for obtaining the multi-scale high-entropy alloy powder A is: The stainless steel ball with a mass ratio of 10:1 and the CoCrFeNiMn high-entropy alloy powder with a particle size of 50 mesh prepared by gas atomization are loaded into the stainless steel ball mill tank of the liquid nitrogen type low-temperature planetary ball mill, and then the stainless steel ball mill tank is filled with After the argon gas, ball milling for 30min at a speed of 300r / min to obtain the multiscale high-entropy alloy powder A in a stainless steel ball mill tank; the ball milling process to obtain the multiscale high-entropy alloy powder B is as follows: the mass ratio is 25:1 200-mesh CoCrFeNiMn high-entropy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com