Ultrahigh-pressure cyclone with normal inlet and automatic sand discharging system

A cyclone and ultra-high pressure technology, applied in the field of separators, can solve the problems of less separation time, low working pressure, and large energy loss, and achieve the effects of improving separation efficiency, separation accuracy, and tangential speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

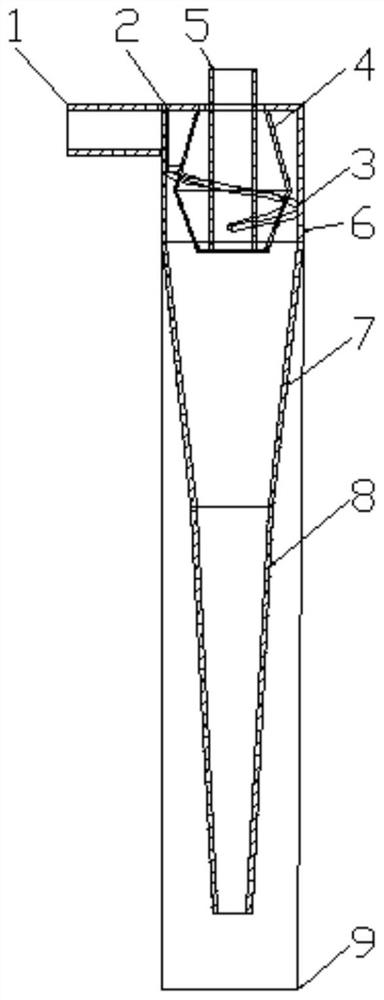

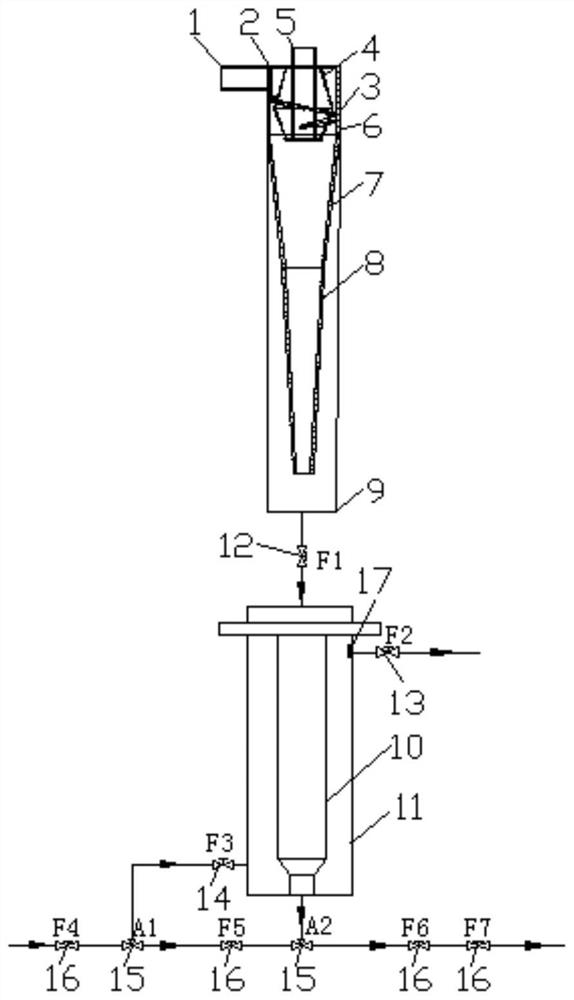

[0037] On the basis of the above-mentioned structure, in this embodiment, the upper part of the swirl tube is also vertically fixed with a speed-up tube 4, which is usually welded or bolted, and the upper and lower ends of the speed-up tube 4 can be closed. Both can be open, and the deflector 3 is located between the speed-increasing cylinder 4 and the swirl cylinder; the interior of the speed-increasing cylinder 4 is also vertically fixed with an overflow pipe 5, which is usually welded or bolted. The two ends of 5 are all exposed, and its lower end is flush with the lower end of speed-increasing tube 4, and the upper end extends vertically upwards out of the upper end of the cyclone tube. During separation, the area of material circulation is reduced through the design of speed-increasing cylinder 4, thereby increasing the rate of material circulation, thereby improving the effect of material separation; the airflow generated during material circulation is discharged from t...

Embodiment 2

[0041] On the basis of Embodiment 1, in this embodiment, the speed-increasing cylinder 4 is a cylinder with thin ends and a thick spindle structure in the middle. The structure is simple and the design is reasonable, which ensures the speed of material circulation, thereby ensuring material separation. Effect.

[0042] The speed-increasing barrel 4 above can adopt a barrel with an inverted cone structure, and the structure adopts a barrel composed of an upper involute and a lower taper, so as to reduce the area of material circulation, thereby increasing the rate of material circulation and ensuring material separation. Effect.

Embodiment 3

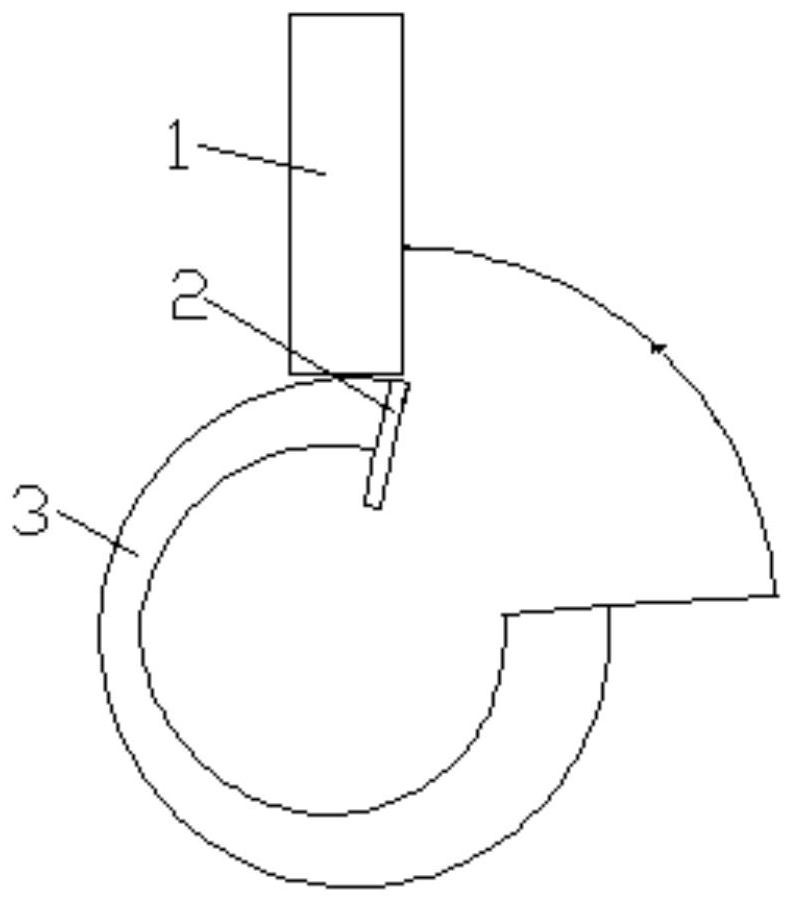

[0044] On the basis of Embodiment 1, in this embodiment, the deflector 3 is a plate body with a spiral plate structure, which is arranged on the speed-increasing cylinder 4 from top to bottom. The structure is simple, the design is reasonable, and the material circulation is prolonged. path, thereby increasing the rate of material circulation, thereby ensuring the effect of material separation.

[0045] The deflector 3 above can be an arc-shaped plate, that is, the middle part is recessed; the deflector 3 can also be a flat plate, and at this time, baffles are welded on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com