Rotary kiln incineration system

A rotary kiln and kiln tail technology, applied in incinerators, rotary drum furnaces, combustion methods, etc., can solve the problems of reducing the service life of refractory castables on the surface of slag extractors, drop of castables, deformation of steel plates, etc., to reduce local The effect of abnormal temperature, reducing steel plate deformation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following is attached Figure 1-6 The application is described in further detail.

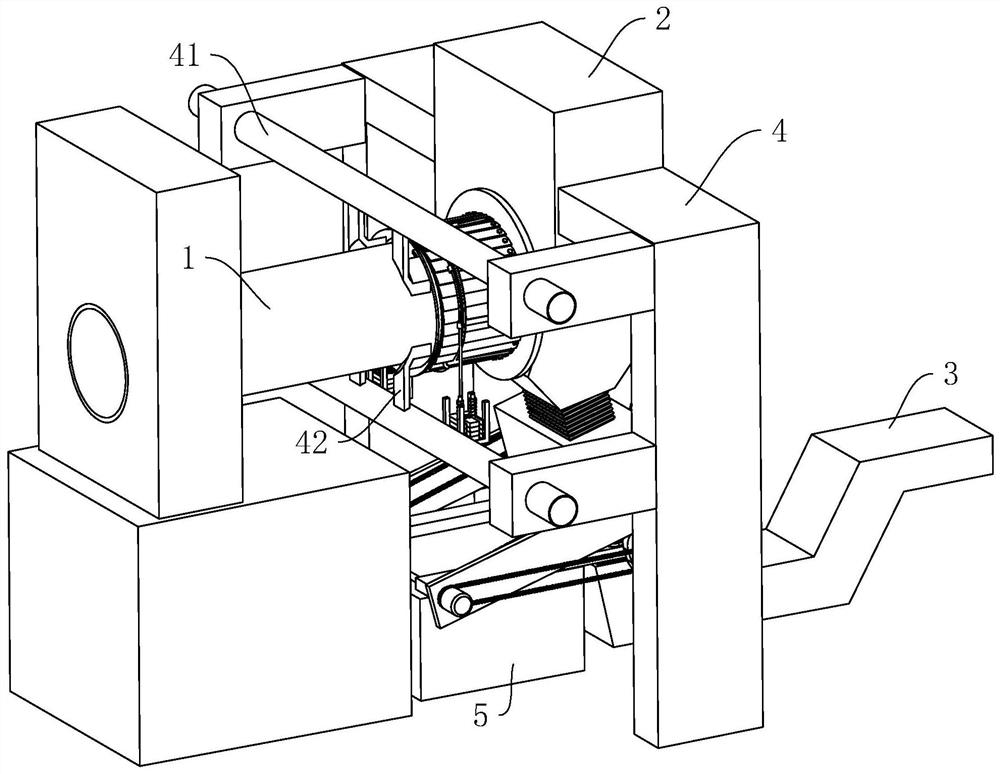

[0062] The embodiment of the present application discloses a rotary kiln 1 incineration system. refer to figure 1 , including rotary kiln 1, secondary combustion chamber 2, and slag removal machine 3. The second combustion chamber 2 is fixed on the mounting frame 4 for installing the second combustion chamber 2, and the kiln tail of the rotary kiln 1 communicates with the second combustion chamber 2, and the slag extractor 3 is located below the discharge port of the second combustion chamber 2.

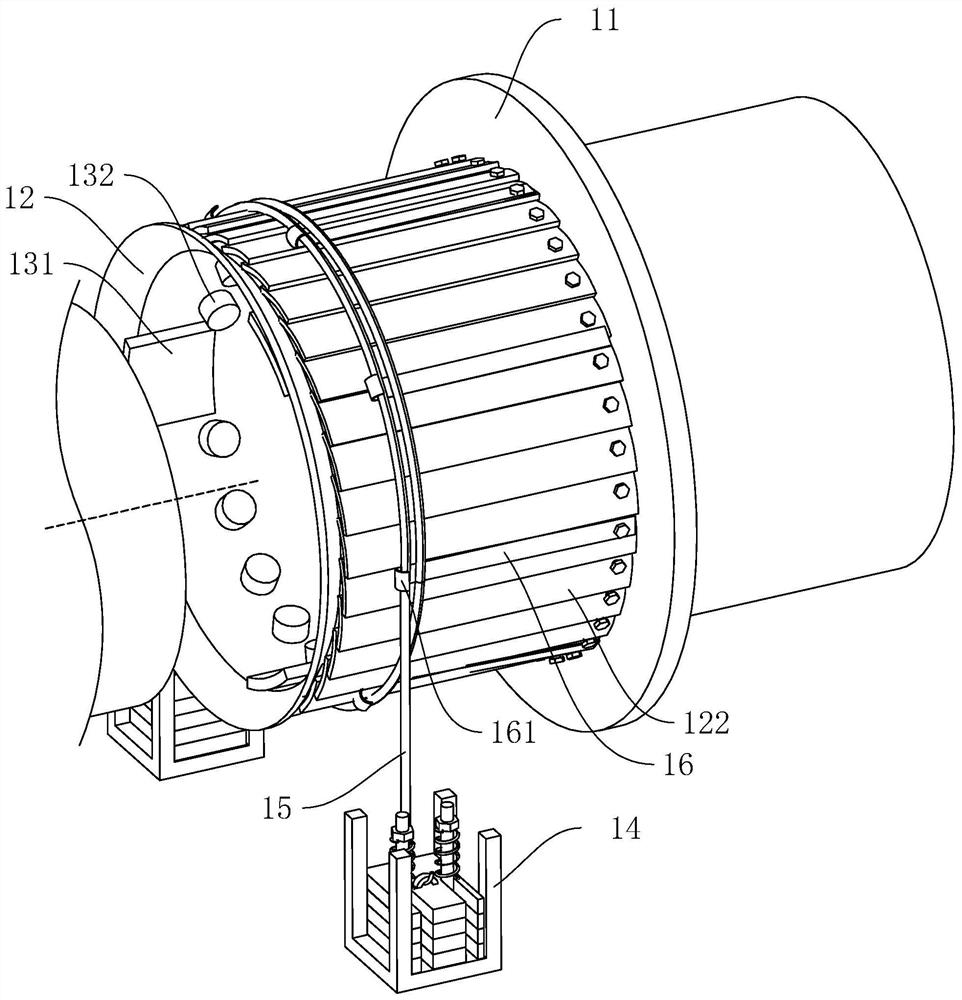

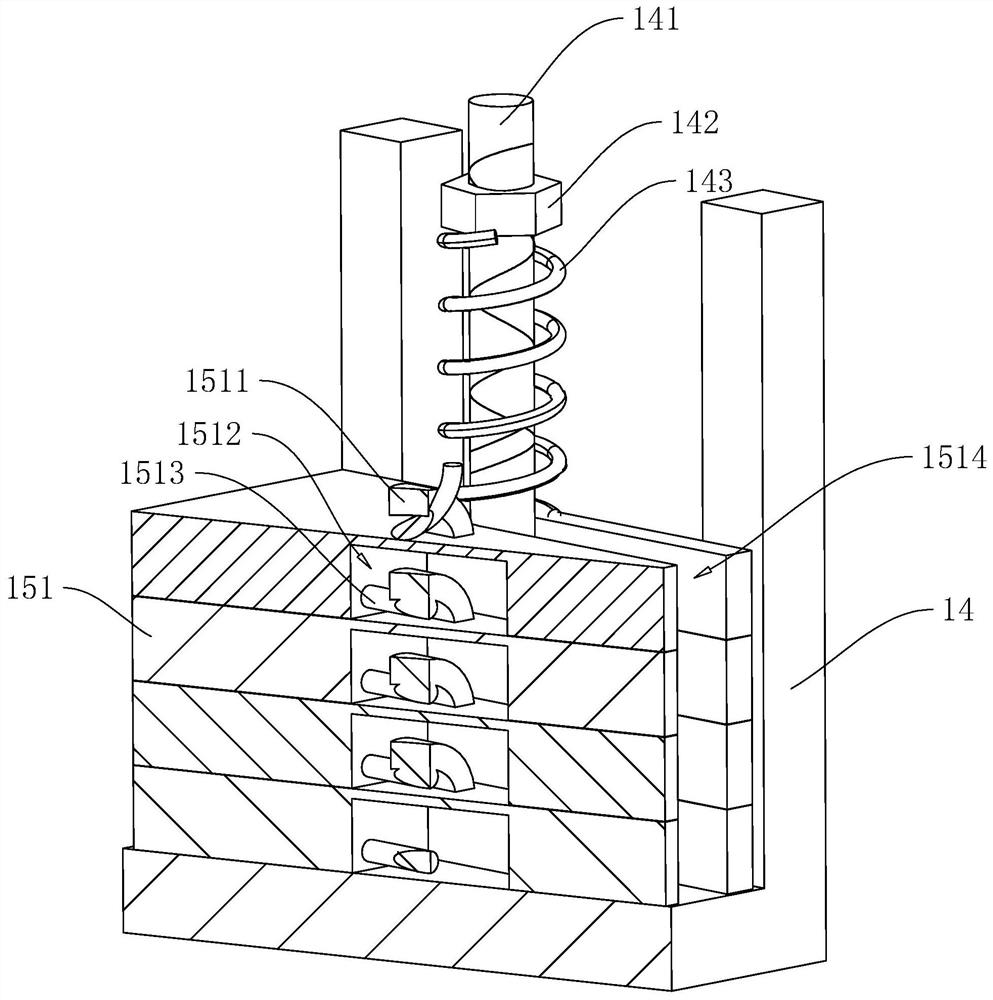

[0063] refer to figure 1 and figure 2 , The outer wall of the kiln tail of the rotary kiln 1 is provided with a cone flange 11, and the cone flange 11 is fixed on the side of the second combustion chamber 2 close to the kiln body. The sealing sleeve 12 is fixed on the end of the kiln body near the kiln tail, and the sealing sleeve 12 is rotatably connected in the cone flange 11 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com