Laser additive manufacturing diffuser crack defect DR detection image processing method

An image detection and laser additive technology, applied in image data processing, image enhancement, image analysis, etc., can solve the problems of less detailed information, unable to enhance target details, low brightness, etc., to improve image contrast and enhance image edge effects , Enhance the effect of image detail information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical scheme and advantages of the present invention clearer, below in conjunction with specific embodiment, and refer to

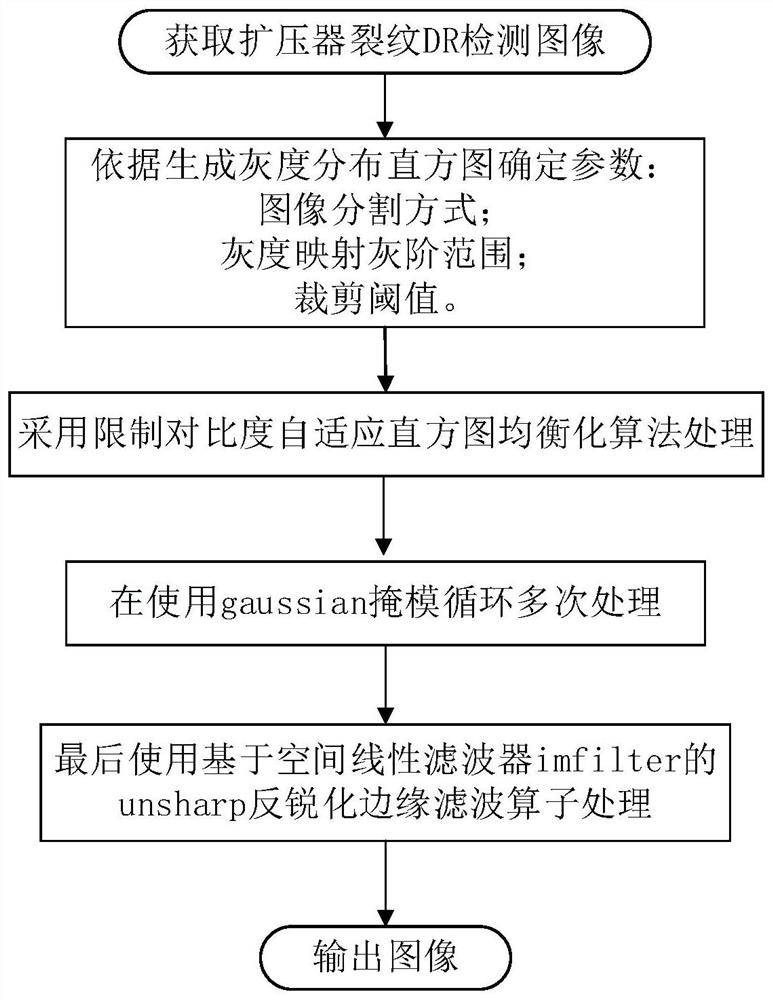

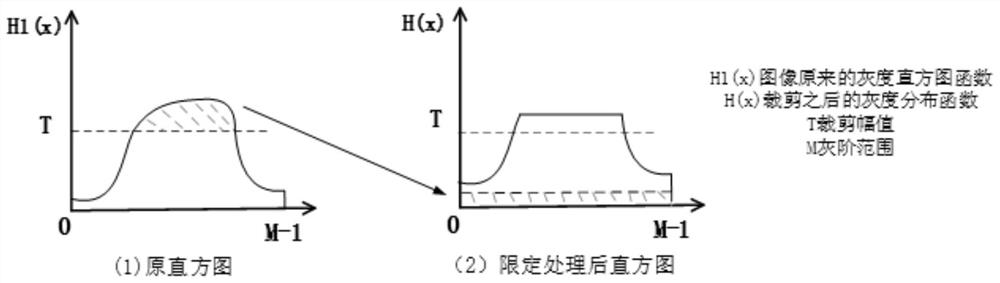

[0040] Accompanying drawing, the present invention is described in further detail. Such as figure 1 As shown, the flow chart of image processing method for DR detection of crack defects in laser additive manufacturing diffuser:

[0041] S1. Use the DR detection system to obtain the DR detection image of the crack in the nickel-based superalloy additive manufacturing diffuser;

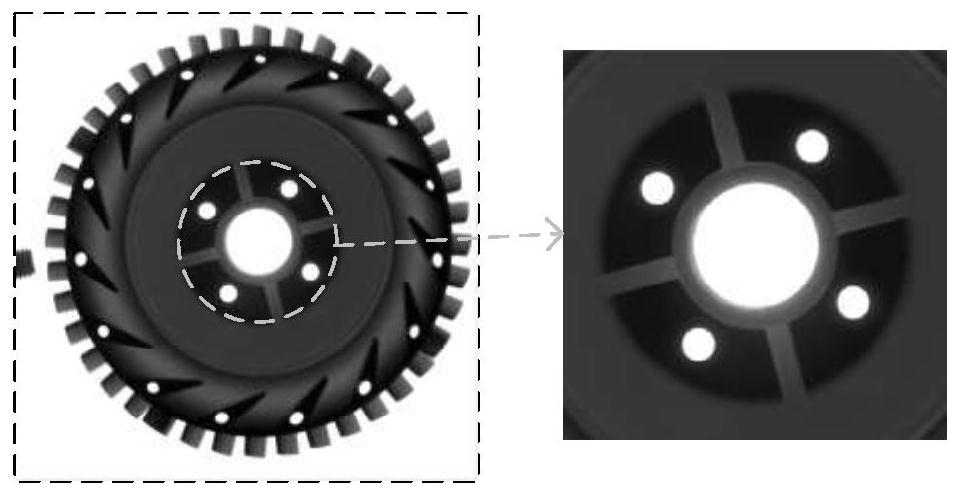

[0042] This nickel-based superalloy additive manufacturing diffuser crack defect DR detection image processing method obtains the nickel-based superalloy additive manufacturing diffuser crack DR detection image, such as figure 2 shown. The DR detection system includes a digital ray system and a digital flat panel detector imaging system. Through these two systems, combined with the DR image acquisition software on the computer, the DR det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com