Composition for forming transparent conductive film and method for preparing transparent conductive film

一种透明导电膜、组合物的技术,应用在分散在不导电无机材料中的导电材料、导电粘合剂、导电涂料等方向,能够解决不宜采用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

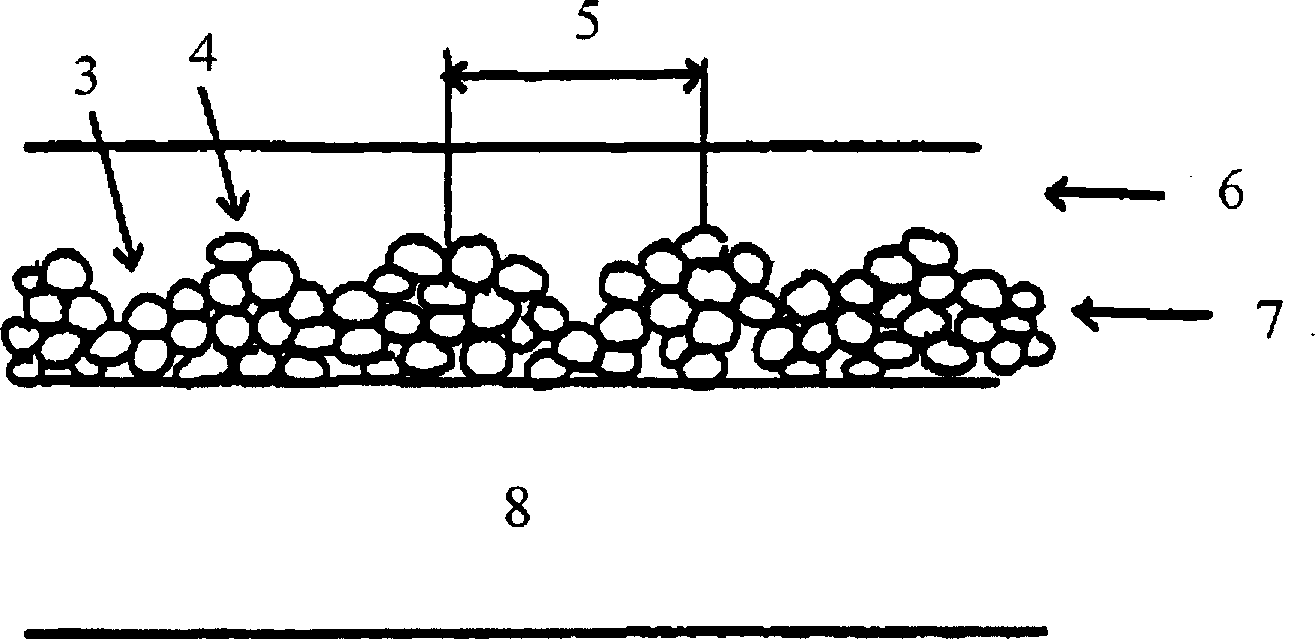

[0079] Preparation method of transparent conductive film of the present invention

[0080] The preparation method of the transparent conductive film of the double-layer structure of the present invention is not particularly limited. For example, the method described below can be used.

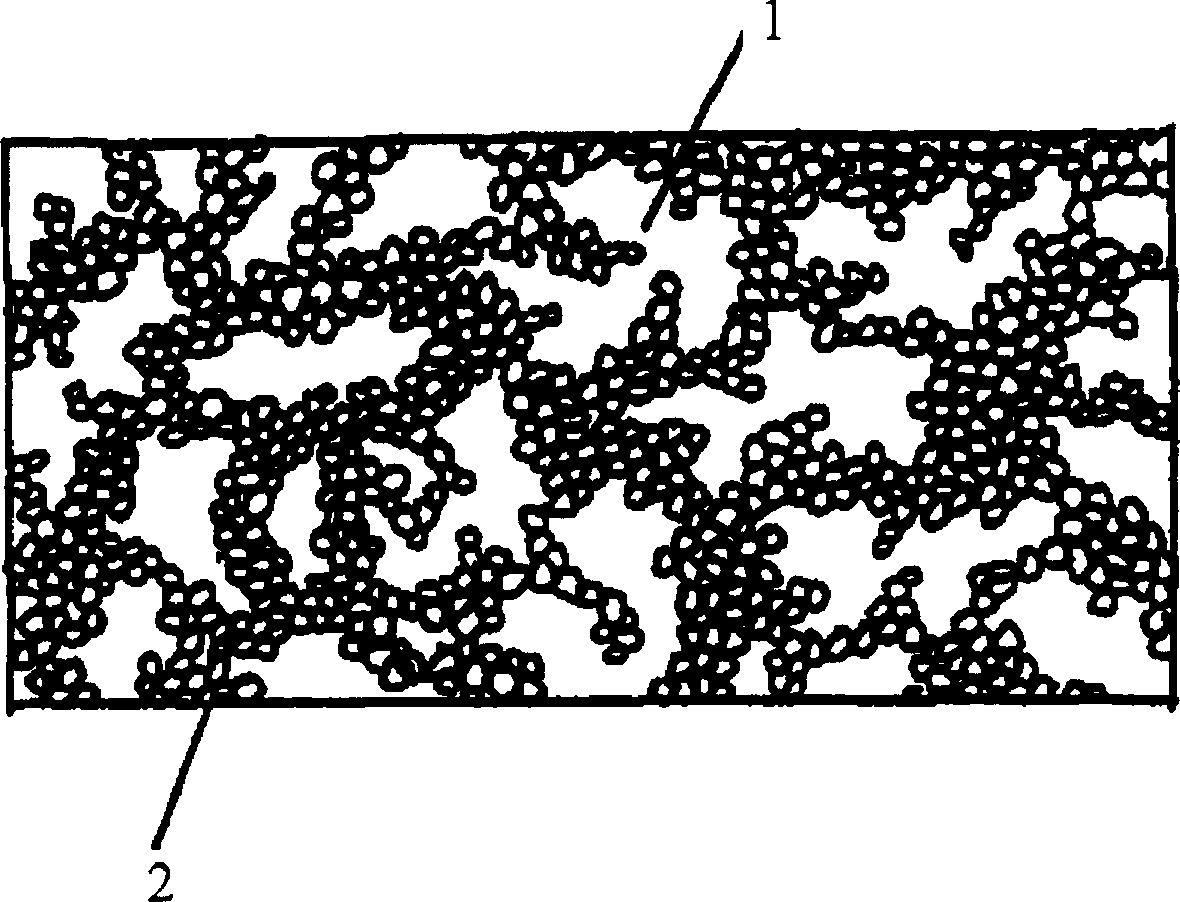

[0081] First, a coating material containing fine metal powder and other required powders (ATO, ITO or black powder) (film-forming composition) used to form the bottom layer is coated on a transparent substrate to form a film containing fine metal powder. The coating material is prepared by dispersing fine metal powder and other randomly selected powders in a suitable solvent. The dispersion can be accomplished by conventional equipment used in the preparation of coating materials.

[0082] The coating material forming the bottom layer may or may not include a binder composed of alkoxysilane (which is at least partially hydrolyzed in advance) that can form a silica matrix after baking. In short, the...

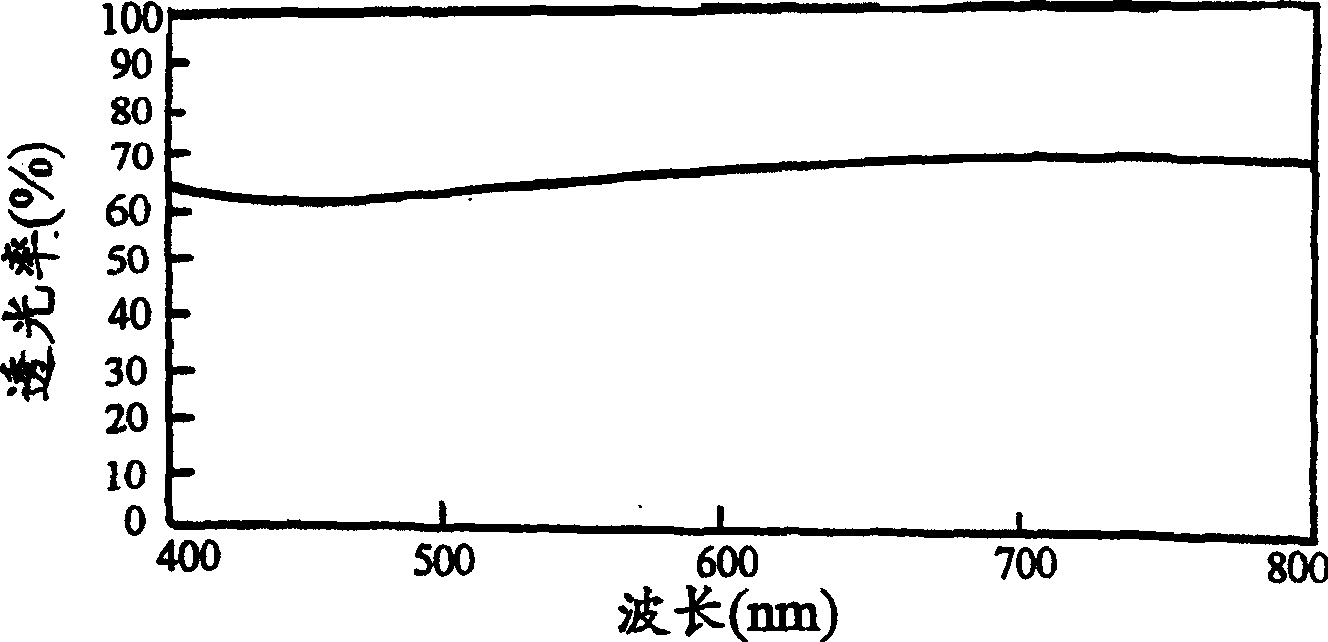

Embodiment 1

[0202] Example 1 relates to a black powder-containing double-layer film prepared using a binder-free coating material forming a primer layer.

[0203] Coating material that forms the primer

[0204] Preparation of siloxane-free primer coating material: Add fine metal powder and black powder to the mixed solvent of isopropanol / 2-isopropoxyethanol at a weight ratio of 80 / 20, if necessary , And the types and proportions of titanium compound, black powder and titanium compound are listed in Table 1. Mix the resulting mixture in a paint mixer with zirconia pellets (diameter 0.3 mm) to disperse the two powders in the solvent . The average primary particle size of both the fine metal powder and the black powder in the coating material is up to 0.1 micrometers. The total content of these two powders in the coating material is 0.7-3.2%, and the viscosity of the coating material is 1.0-1.6 cps.

[0205] The conformity of the titanium compounds used in Table 1 has the following meanings:

[...

Embodiment 2

[0228] Example 2 relates to the preparation of a double-layer film using a binder-containing undercoat layer-forming coating material, wherein the underlayer conductive coating contains black powder.

[0229] Coating material that forms the primer

[0230] The details of this example are the same as those in Example 1, except that tetraethoxysilane (ethyl silicate) is added as a binder, and the added amount is 10 parts by weight relative to 10 parts by weight of fine metal powder and black powder. Parts (converted to silica), and a small amount of hydrochloric acid can be added as a hydrolysis catalyst.

[0231] Coating material forming the top coat

[0232] Same as Example 1

[0233] Film forming method

[0234] The procedure is the same as that in Example 1, except that after coating the base coat-forming coating material on the substrate with the aid of a spin coater, the coated substrate is heated at 50° C. for 5 minutes in the open air. The baking of the undercoat layer is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com