Plant slice and preparation method and cigarette substitute

A flake and plant technology, applied in the field of cigarette substitutes, plant flakes and their preparation, can solve the problems of low market acceptance, inability to meet the needs of consumers, unstable aerosol generation, etc., and achieves widening the generation temperature range, The effect of improving the suction experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Embodiments of the present invention provide a method for preparing plant flakes, comprising the following steps:

[0027] S10, provide 60 mesh ~ 800 mesh plant powder;

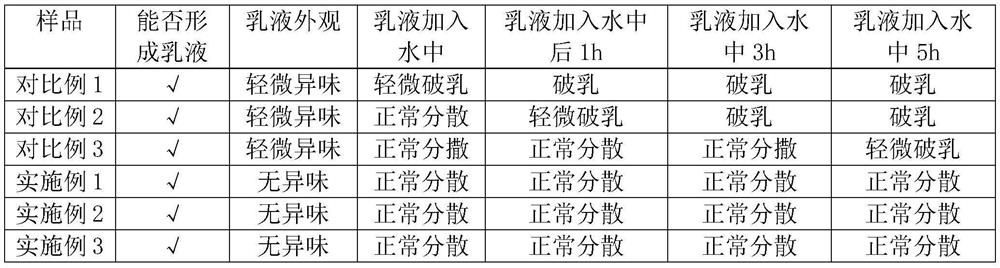

[0028] S20, emulsifying at least one polyhydric alcohol hydrophilic aerosol generating agent and at least one natural aliphatic ester lipophilic aerosol generating agent to form an aerosol generating agent emulsion, the emulsifier used is gum arabic, tragacanth, One or more of gelatin;

[0029] S30, adding the plant powder, the aerosol generator emulsion, fiber, and adhesive to the water medium, and uniformly mixing to obtain a slurry;

[0030] S40, the slurry is spread on the receiving object by tape casting, and the plant flakes are obtained after drying.

[0031] The preparation method of the plant flake provided by the embodiment of the present invention adopts at least one of gum arabic, tragacanth, and gelatin as an emulsifier, emulsifying a polyhydric alcohol hydrophilic aerosol generating age...

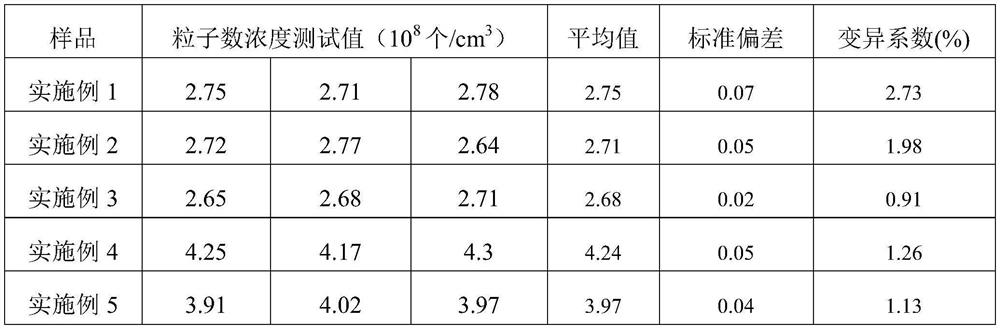

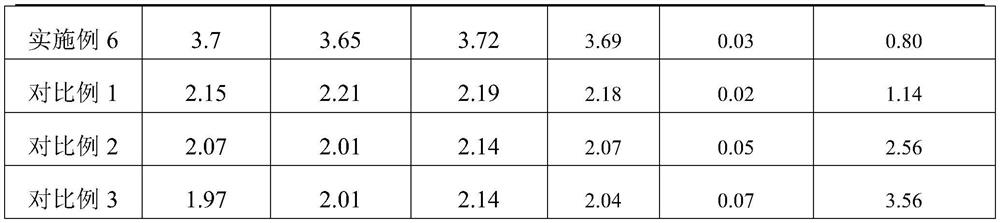

Embodiment 1

[0068] (1) 20 parts of kudzu root and 20 parts of tangerine peel are respectively crushed in a low-temperature pulverizer, and the pulverization temperature is between 20 and 50 ° C. The obtained powder is mixed and stirred evenly and passed through a 160-mesh sieve, which cannot meet the fineness requirement Carry out pulverizing again until completely passing through a 160 mesh sieve to obtain plant powder.

[0069] (2) Add 10 parts of glycerol and 2 parts of cocoa butter to 20 parts of water, add 0.5 parts of emulsifier gum arabic, and disperse at high speed for 5 minutes under the condition of 2000r / min to obtain an aerosol generating agent lotion.

[0070] (3) 5 parts of softwood pulp fiber, 1 part of guar gum and 1 part of chitosan, 0.1 part of sodium citrate, 3 parts of tangerine peel flavor, 1 part of caramel flavor, 1 part of 400 mesh calcium carbonate powder, 400 parts The water is uniformly mixed with the plant powder obtained in step (1) and step (2), and the aero...

Embodiment 2

[0073] (1) 20 parts of kudzu root and 20 parts of tangerine peel are respectively crushed in a low-temperature pulverizer, and the pulverization temperature is between 20 and 50 ° C. The obtained powder is mixed and stirred evenly and passed through a 160-mesh sieve, which cannot meet the fineness requirement Carry out pulverizing again until completely passing through a 160 mesh sieve to obtain plant powder.

[0074] (2) Add 10 parts of glycerol and 2 parts of cocoa butter to 20 parts of water, add 0.5 parts of emulsifier tragacanth gum, and disperse at high speed for 5 minutes under the condition of 2000r / min to obtain an aerosol Builder emulsion.

[0075] (3) 5 parts of softwood pulp fiber, 1 part of guar gum and 1 part of chitosan, 0.1 part of sodium citrate, 3 parts of tangerine peel flavor, 1 part of caramel flavor, 1 part of 400 mesh calcium carbonate powder, 400 parts The water is uniformly mixed with the plant powder obtained in step (1) and step (2), and the aerosol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com