A kind of preparation method of high-purity monodisperse porous silica ball

A porous silicon oxide, monodisperse technology, applied in the field of nanomaterials, can solve the problems of easily broken balls, complex preparation process of soft template method, narrow pore size distribution range, etc., achieve good shape, wide pore size distribution range, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Using magnetic stirring water bath pot, at a speed of 1200rpm, 40 ° C, 100mL methanol and 100mL deionized water were mixed to obtain a mixture of 1, 4.00g PTMS and 6.00g TEOS were mixed to obtain a mixture 2, 20mL of ammonia water was added to the mixture 1, the mixture 3 was obtained, the mixture 2 was added to the mixture 3, and the mixture was continuously stirred for 7h to obtain a phenyl-containing silica sol.

[0034] (2) The phenyl-containing silica sol is washed three times by centrifugation with absolute ethanol at a speed of 9000rpm, and then the centrifugal product is placed in an oven and dried at 100 °C for 10h, and the resulting white powder is phenyl-containing silica.

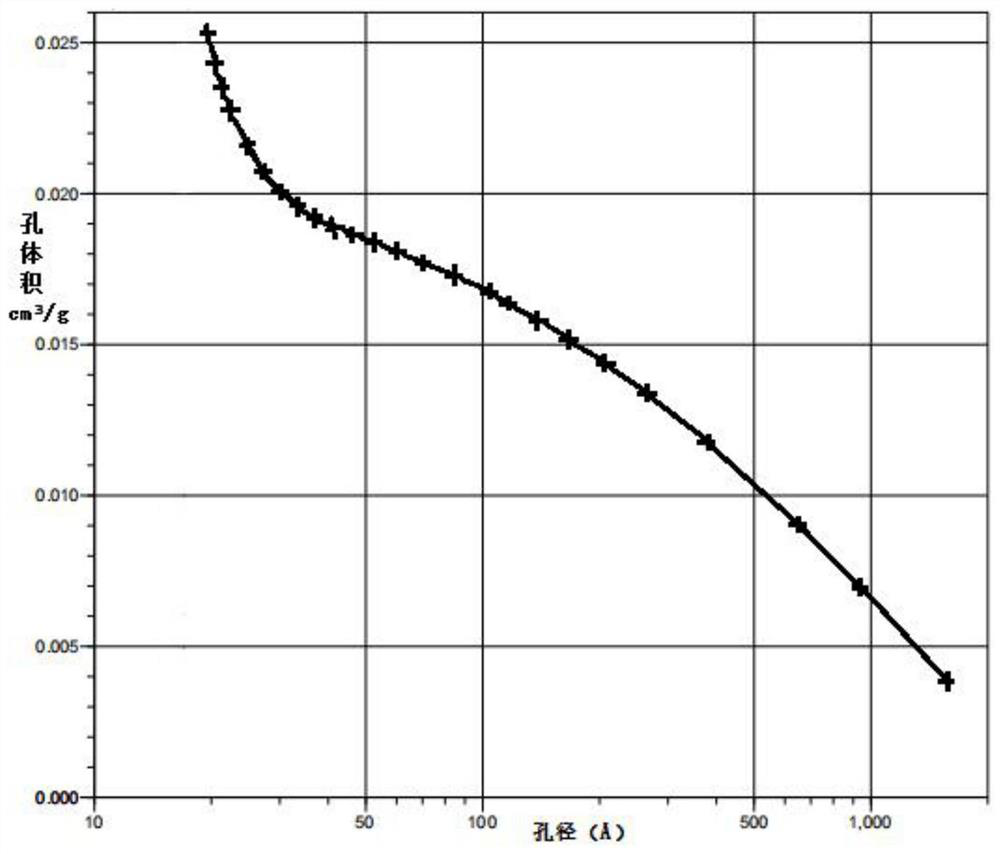

[0035] (3) The above-mentioned phenyl-containing silica is placed in a muffle furnace, heated to 600 °C, the heating rate is 3 °C / min, and the heat preservation is 6h to obtain a high-purity porous silica ball.

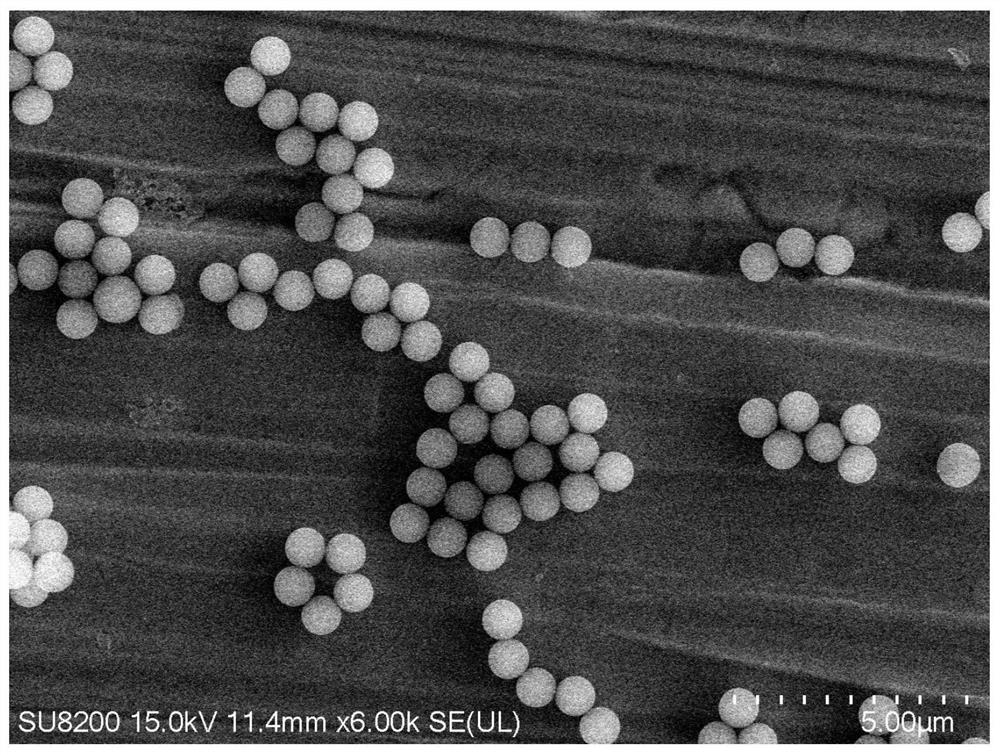

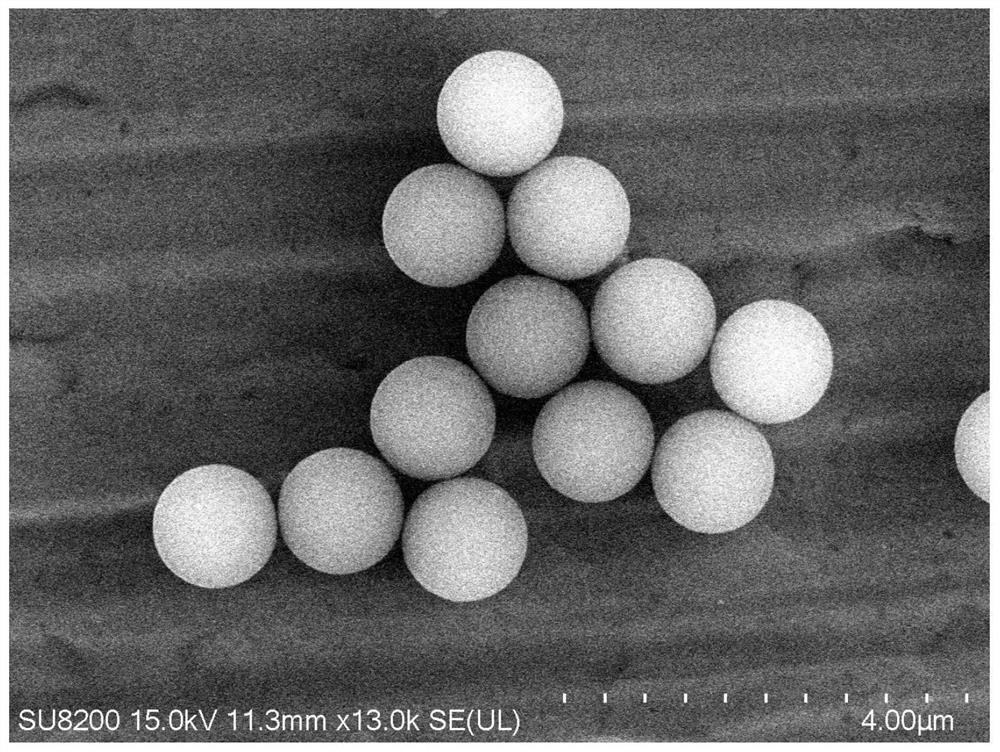

[0036] Figure 1 Scanning electron microscopy of porous silica oxide balls ...

Embodiment 2

[0038] The specific operating steps of Example 2 are the same as those of Example 1, the difference is that the step of Example 2 (1) in PTM is 3.00g, TEOS is 7.00g.

[0039] Figure 3Scanning electron microscopy of the porous silica ball prepared for embodiment 2 of the present invention, as can be seen from the figure, the sample is spherical, with an average particle size of 1.25μm.

Embodiment 3

[0041] The specific operating steps of Example 3 are the same as In Example 1, the difference is that the volume of ammonia in step (1) of Example 3 is 14mL, and the particle size of the resulting porous silica sphere is 0.4μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com