A kind of processing method of moso bamboo spin slice

A processing method and technology of moso bamboo, which are applied in the field of bamboo product processing, can solve the problems of low utilization rate of moso bamboo, large loss of rotary cutting machine tools, inconsistent fiber bundle density, etc., and achieve the goal of improving the utilization rate of moso bamboo, reducing waste rate and reducing loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

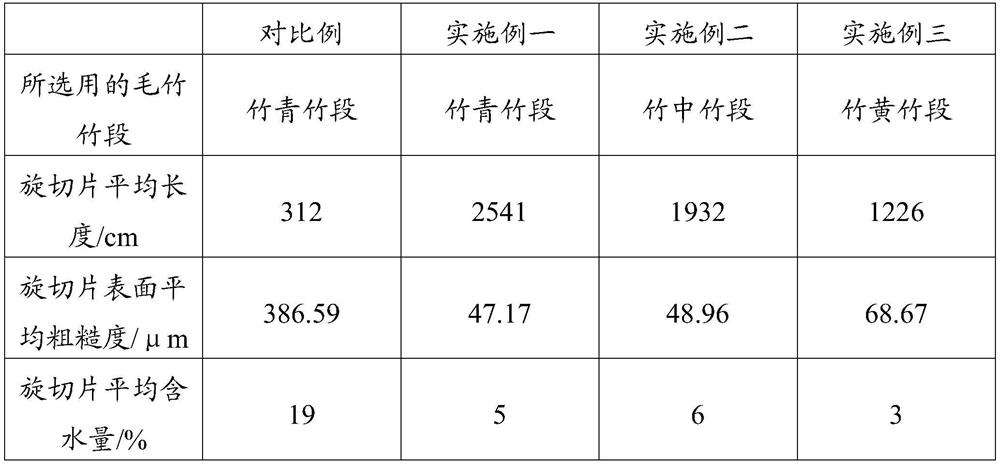

Embodiment 1

[0035] A kind of processing method of the bamboo green bamboo segment rotary slice of moso bamboo, comprises the steps:

[0036] Step 1: select 3-year-old moso bamboo sections with a wall thickness of more than 1.5cm;

[0037] Step 2: Put the bamboo green bamboo section into 70°C water and cook for 8 hours, so that the water content of the moso bamboo section reaches more than 60%. The segment is flipped;

[0038] Step 3: Wipe the excess water on the surface of the bamboo green bamboo section after cooking with a hot cloth or blow it dry with warm air, and keep the temperature of the green bamboo section at 65°C or higher during the rotary cutting process, and then reduce the temperature to 65°C The above green bamboo section is fixed on the rotary cutting machine and carries out rotary cutting with the spindle speed of 85r / min, the cutter feed of 0.2mm / r to obtain the rotary slice of moso bamboo;

[0039] Step 4: Sandwich the rotary slices of moso bamboo between two layers ...

Embodiment 2

[0042] A kind of processing method of the bamboo section rotary slice of moso bamboo, comprises the steps:

[0043] Step 1: Select the 3-year-old moso bamboo section with a wall thickness of more than 1.5cm;

[0044] Step 2: Put the bamboo section in 75°C water and cook for 7.5 hours, so that the water content of the bamboo section reaches more than 60%. The bamboo section is turned over;

[0045]Step 3: Wipe the excess moisture on the surface of the bamboo section after cooking with a hot cloth or blow it dry with warm air, and keep the temperature of the bamboo section above 70°C during the rotary cutting process, and then reduce the temperature to 70°C The above bamboo section is fixed on the rotary cutting machine and carries out rotary cutting with the spindle speed of 85r / min, the cutter feed rate of 0.2mm / r to obtain the rotary slice of moso bamboo;

[0046] Step 4: Sandwich the rotary slices of moso bamboo between two layers of melt-blown cloth, and then pass through...

Embodiment 3

[0049] A kind of processing method of the bamboo yellow bamboo section rotary slice of moso bamboo, comprises the following steps:

[0050] Step 1: Select 3-year-old Phyllostachys edulis with a wall thickness of more than 1.5cm;

[0051] Step 2: put the bamboo yellow bamboo section into 85°C water and cook for 7 hours, so that the water content of the moso bamboo section reaches more than 60%. The bamboo yellow bamboo section is turned over;

[0052] Step 3: Wipe the excess moisture on the surface of the bamboo yellow bamboo section after cooking with a hot cloth or blow dry with warm air, and keep the temperature of the bamboo yellow bamboo section above 75°C during the rotary cutting process, and then reduce the temperature The bamboo and yellow bamboo sections above 75°C are fixed on a rotary cutting machine to perform rotary cutting at a spindle speed of 85r / min and a tool feed rate of 0.2mm / r to obtain rotary slices of moso bamboo;

[0053] Step 4: Sandwich the rotary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com