A method for preparing conductive bioscaffolds based on self-excited electrostatic field-driven melt-jet 3D printing

A bio-stent and 3D printing technology, applied in the field of 3D printing, can solve the problems that it is difficult to ensure the high-precision concentricity of the ring electrode and the nozzle, affect the high-precision printing and high-stable electric field requirements, and the outer wall of the extraction electrode nozzle does not fit, etc., to achieve convenient replacement , good print quality, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

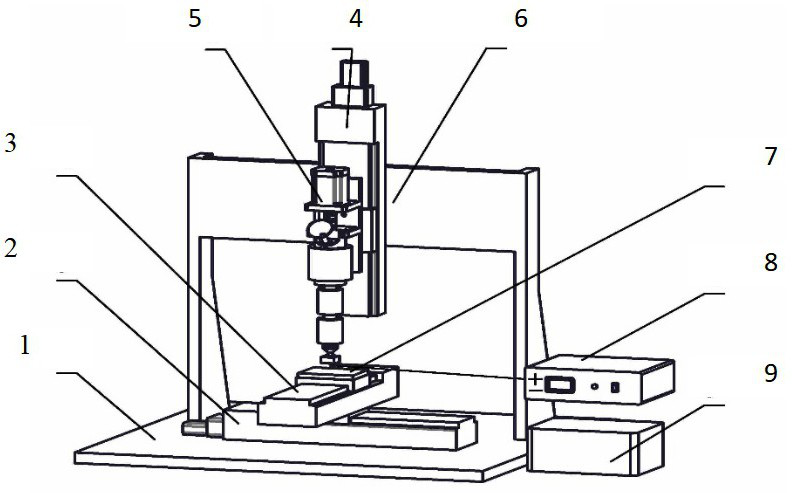

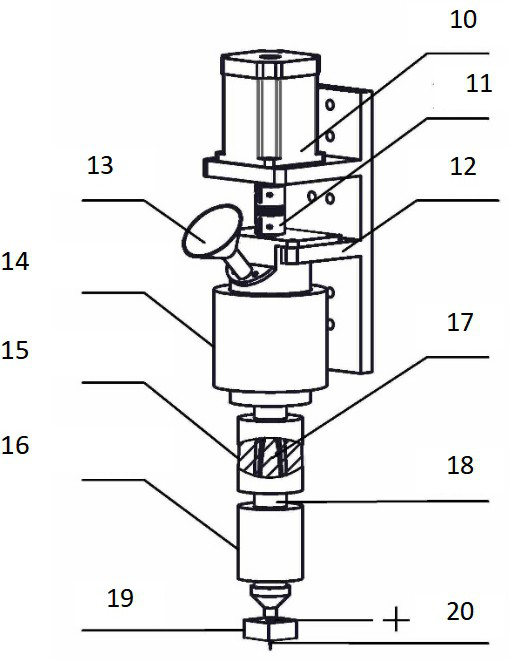

[0039] The accompanying drawings that form a part of the present application are used to provide further understanding of the present application, and the schematic embodiments and descriptions of the present application are used to explain the present application and do not constitute improper limitations on the present application.

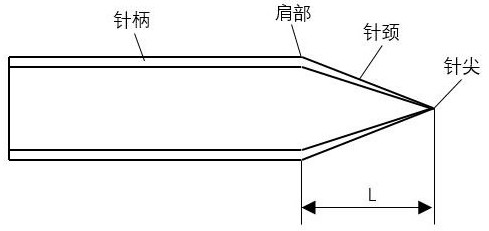

[0040] In this application, an extraction electrode is formed by attaching, winding and fixing a conductive patch on the shoulder of a glass nozzle. The conductive patch is connected to a DC power supply, and the nozzle and the substrate are electrostatically excited, resulting in the rearrangement of charges on the substrate and the distribution on the upper surface of the substrate. Negative charges, positive charges are distributed on the lower surface, and an electric field is formed between the nozzle and the substrate. Under the action of the electric field generated by the high-voltage DC power supply, the printing material extruded to the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com