Production method of high-quality 4-(2-hydroxyethyl)piperazine-1-ethanesulfonic acid

A technology of hydroxyethylpiperazineethanesulfonic acid and hydroxyethylpiperazine, which is applied in the production field of high-quality 4-hydroxyethylpiperazineethanesulfonic acid, can solve the problem of cost, process operability, raw material utilization and resource integration Insufficient utilization, not widely used, and high cost of dibromoethane, to achieve the effect of product quality and purity assurance, low cost, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

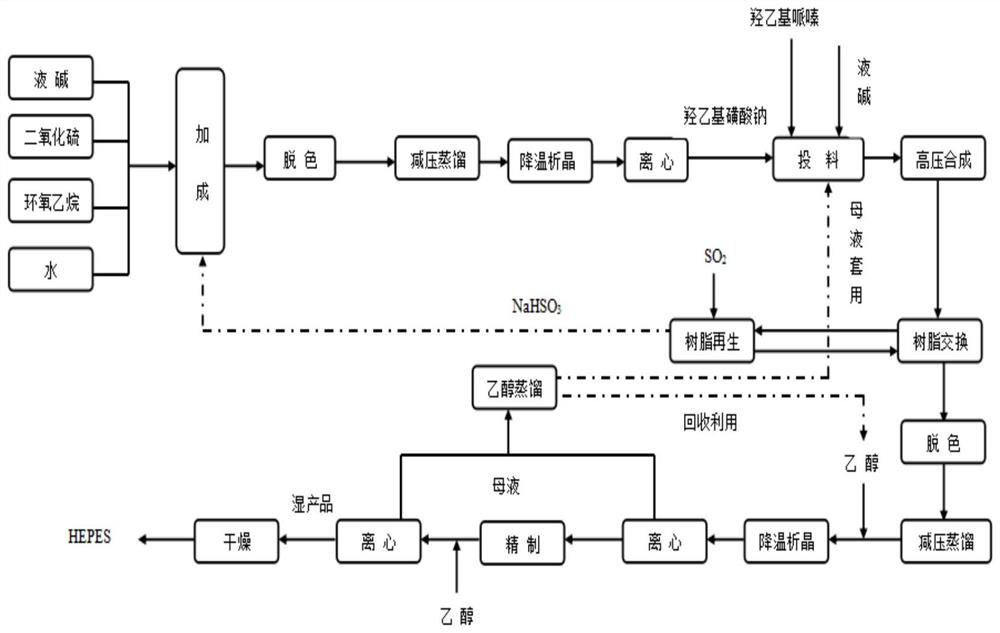

Method used

Image

Examples

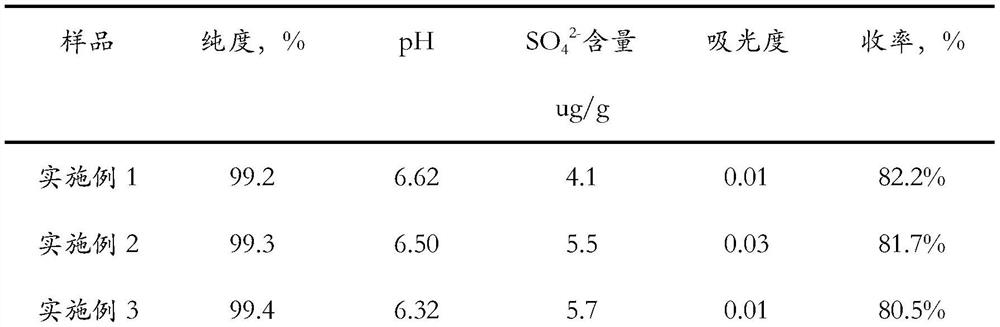

Embodiment 1

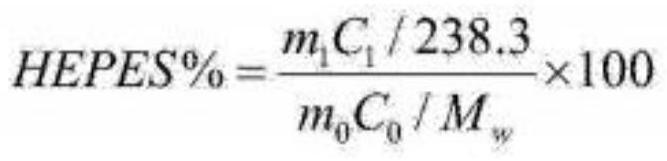

[0022] A kind of production method of high-quality 4-hydroxyethylpiperazineethanesulfonic acid, its preparation method is as follows:

[0023] (1) Preparation of sodium isethionate: put a certain amount of liquid caustic soda and purified water into the addition reactor, control the temperature at 80°C, and then feed SO into the reactor 2 , control the pH = 5.5; then feed ethylene oxide until the pH = 6.5; and so on, until the reactants are completely converted. The sodium isethionate synthetic solution synthesized by the reaction is decolorized and filtered, and a certain amount of water is removed by vacuum distillation, and the temperature is lowered for crystallization and centrifugation to obtain the sodium isethionate product.

[0024] (2) Condensation addition of 4-hydroxyethylpiperazine sodium ethanesulfonate: sodium isethionate obtained in step (1): hydroxyethylpiperazine according to molar ratio=1:0.8, catalyst according to hydroxyethylpiperazine The ratio of 2.5% o...

Embodiment 2

[0029]A kind of production method of high-quality 4-hydroxyethylpiperazineethanesulfonic acid, its preparation method is as follows:

[0030] (1) Preparation of sodium isethionate: put a certain amount of liquid caustic soda and purified water into the addition reactor, control the temperature at 70°C, and then feed SO into the reactor 2 , control the pH = 6.0; then feed ethylene oxide until the pH = 7.0; and circulate like this until the reactants are completely converted. The sodium isethionate synthetic solution synthesized by the reaction is decolorized and filtered, and a certain amount of water is removed by vacuum distillation, and the temperature is lowered for crystallization and centrifugation to obtain the sodium isethionate product.

[0031] (2) Condensation addition of 4-hydroxyethylpiperazine sodium ethanesulfonate: sodium isethionate obtained in step (1): hydroxyethylpiperazine according to molar ratio = 1:1, catalyst according to hydroxyethylpiperazine The rat...

Embodiment 3

[0036] A kind of production method of high-quality 4-hydroxyethylpiperazineethanesulfonic acid, its preparation method is as follows:

[0037] (1) Preparation of sodium isethionate: put a certain amount of liquid caustic soda and purified water into the addition reactor, control the temperature at 75°C, and then feed SO into the reactor 2 , control the pH = 6.0; then feed ethylene oxide until the pH = 6.5; and circulate like this until the reactants are completely converted. The sodium isethionate synthetic solution synthesized by the reaction is decolorized and filtered, and a certain amount of water is removed by vacuum distillation, and the temperature is lowered for crystallization and centrifugation to obtain the sodium isethionate product.

[0038] (2) Condensation addition of 4-hydroxyethylpiperazine sodium ethanesulfonate: sodium isethionate obtained in step (1): hydroxyethylpiperazine according to molar ratio=1:1.5, catalyst according to hydroxyethyl piperazine The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com