Supercritical CO with uniform combustion and anti-corrosion and anti-coking 2 Boilers and Boiler Systems

A uniform combustion and anti-corrosion technology, applied in the direction of combustion air/fuel supply, combustion chamber, combustion type, etc., can solve the problems of low oxygen concentration near the wall, uneven combustion distribution, threatening boiler safety, etc. temperature problems, avoid high temperature corrosion and coking slag, reduce the effect of peak heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

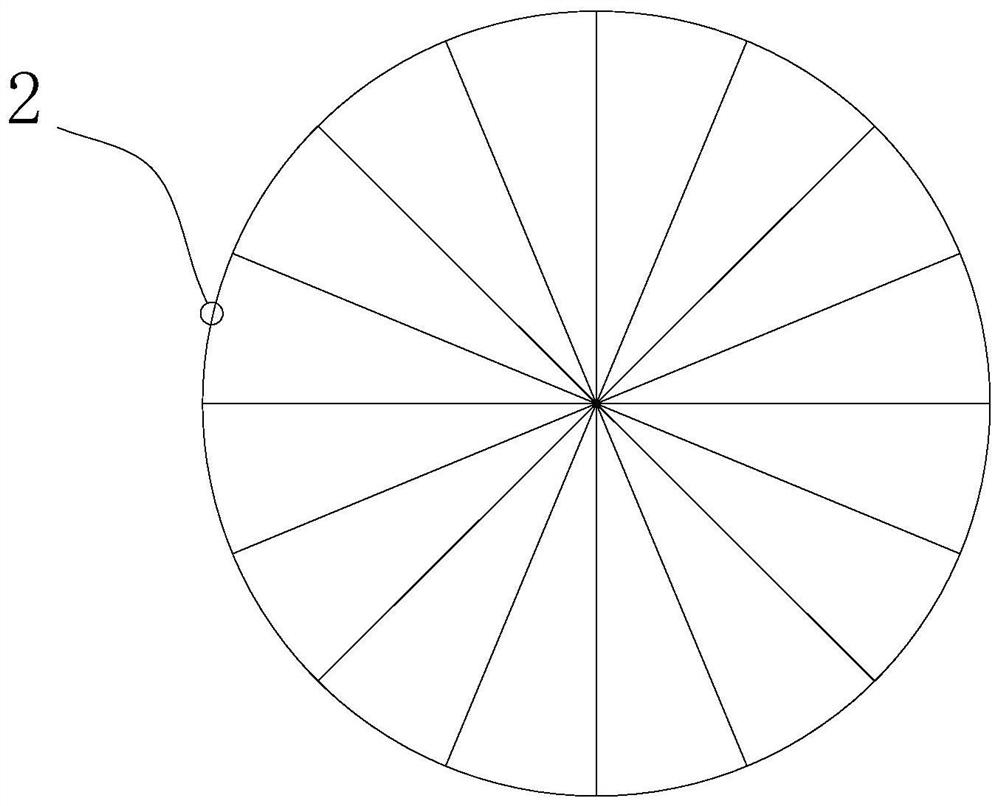

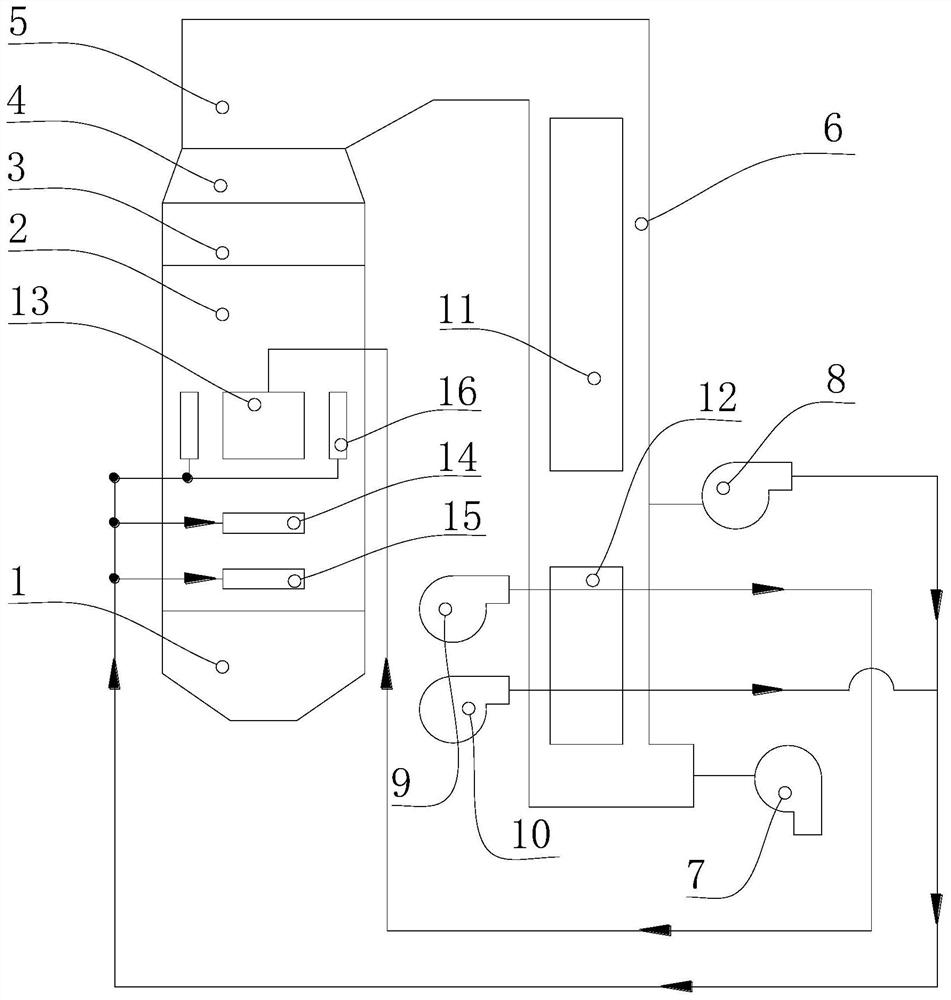

[0044] like figure 1 As shown, the supercritical carbon dioxide boiler system described in Example 1 includes an ash hopper 1, a main combustion chamber 2, an upper furnace 3, a flame angle 4, a horizontal flue 5, a tail flue 6, an induced draft fan 7, and a recirculation fan 8 , a primary blower 9 and a secondary blower 10, the ash hopper 1, the main combustion chamber 2, the upper furnace 3 and the refraction angle 4 are connected sequentially from bottom to top, and one end of the horizontal flue 5 is connected to the upper end of the refraction angle 4 Connected, one end of the tail flue 6 communicates with the other end of the horizontal flue 5, the air inlet of the induced draft fan 7 communicates with the other end of the tail flue 6, and is used for The flue gas is extracted from the inside to the outside, and the tail flue 6 is provided with a tail heating surface 11 and an air preheater 12 sequentially from one end close to the horizontal flue 5 to the other end.

...

Embodiment 2

[0050] like Figure 4 As shown, the supercritical carbon dioxide boiler system described in Example 2 includes an ash hopper 1, a main combustion chamber 2, an upper furnace 3, a flame angle 4, a horizontal flue 5, a tail flue 6, an induced draft fan 7, and a recirculation fan 8 , a primary blower 9 and a secondary blower 10, the ash hopper 1, the main combustion chamber 2, the upper furnace 3 and the refraction angle 4 are connected sequentially from bottom to top, and one end of the horizontal flue 5 is connected to the upper end of the refraction angle 4 Connected, one end of the tail flue 6 communicates with the other end of the horizontal flue 5, the air inlet of the induced draft fan 7 communicates with the other end of the tail flue 6, and is used for The flue gas is extracted from the inside to the outside, and the tail flue 6 is provided with a tail heating surface 11 and an air preheater 12 sequentially from one end close to the horizontal flue 5 to the other end.

...

Embodiment 3

[0057] The supercritical carbon dioxide boiler system described in embodiment 3 comprises a main combustion chamber 2, an upper furnace 3, a flame angle 4, a flue, an induced draft fan 7, a recirculation fan 8, a primary fan 9 and a secondary fan 10, and the upper furnace The lower end of the furnace 3 communicates with the upper end of the main combustion chamber 2, and the upper end of the upper furnace 3 communicates with one end of the flue through a flame angle 4, and the flue is provided with a tail heating surface 11 and air preheating 12, the air inlet of the induced draft fan 7 communicates with the tail of the flue.

[0058] The refraction angle 4 in this embodiment is in the shape of a truncated cone, and the included angle between the side wall of the refraction angle 4 and the horizontal plane is 50°.

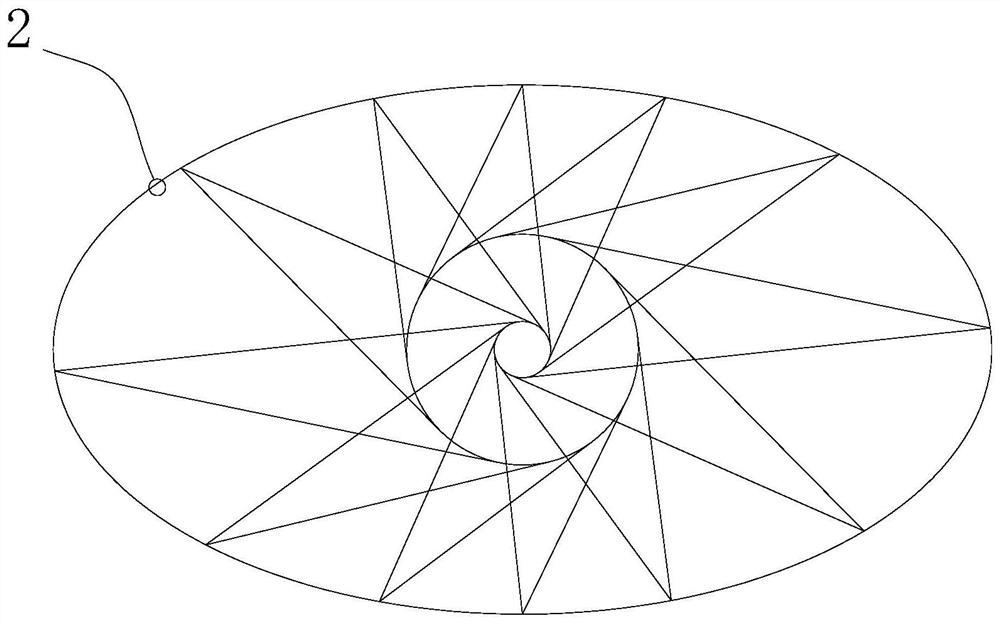

[0059] like Figure 5 As shown, the cross-section of the main combustion chamber 2 is a regular hexagon, and sixteen side walls of the main combustion chamber 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com