Method for simulating silicon dioxide coated calcium fluoride based on Materials Studio

A calcium fluoride-coated, simulation method technology, applied in the field of computer simulation, can solve problems such as lack of research at the molecular level, and achieve the effect of reducing research and development costs and saving experimental resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

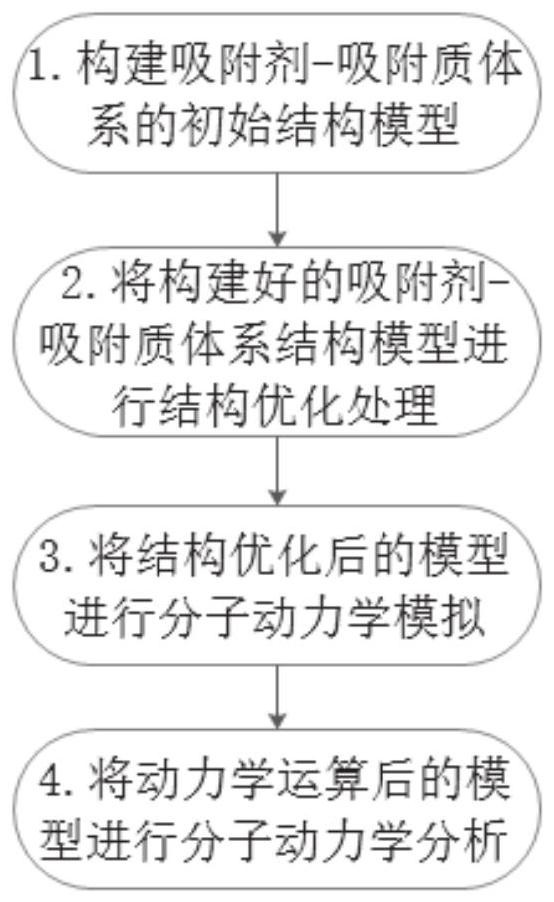

[0041]As attachedfigure 1 As shown, a simulation method of silica-coated calcium fluoride based on Materials Studio. In this embodiment, silica and calcium fluoride are used as the research object, which specifically includes the following steps:

[0042](1) Build initial models of silica and calcium fluoride;

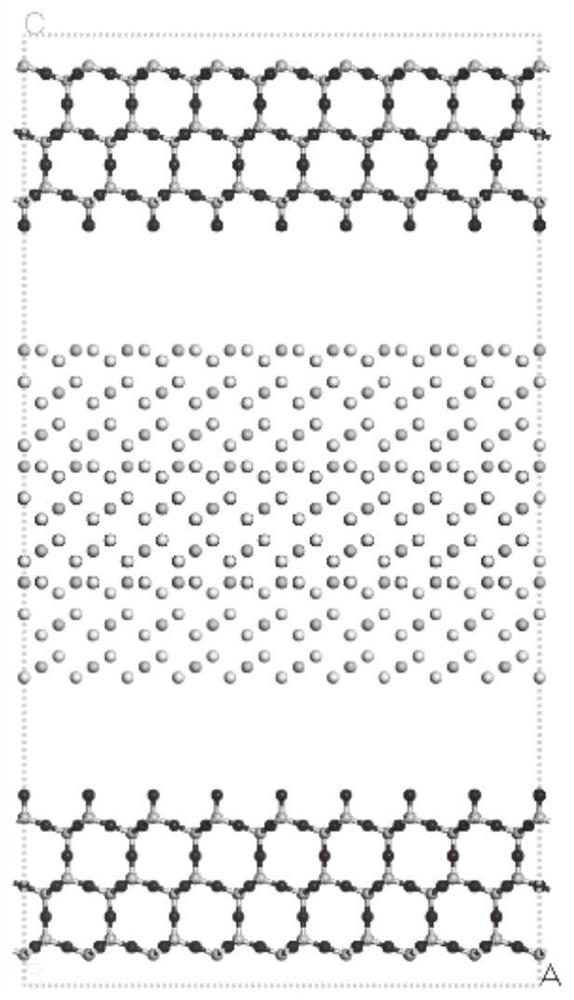

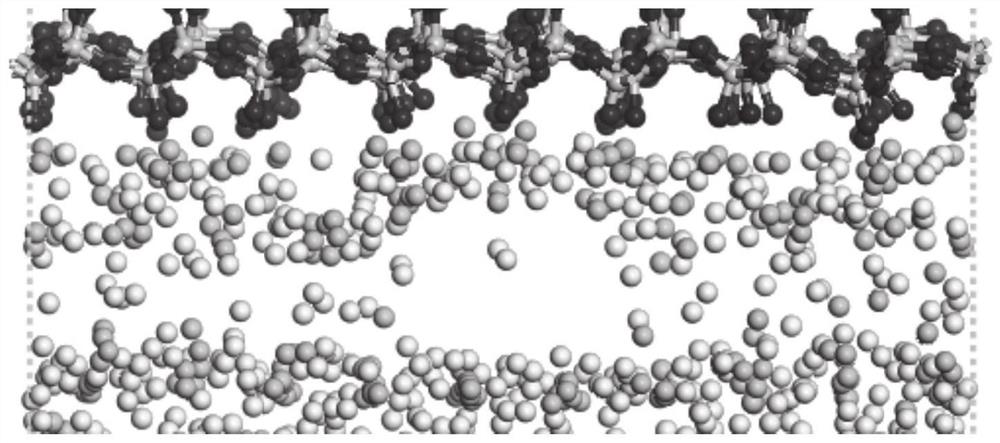

[0043]Use the Visualizer interface in the Materials Studio software to build the molecular structure model of silica and calcium fluoride, and cut the constructed model. Among them, layer 1 and layer 3 of the model are silica, and two types can be obtained after cutting. Terminal surface: O terminal and Si-O. The surface of O terminal is used as layer 1 and layer 3 of Model 1, and the surface of Si-O terminal is used as layer 1 and layer 3 of Model 2. The upper surface atoms of layer 2 are F and Ca For the mixed surface, the number of F and Ca is 100, and the number of atoms on the bottom surface is F, and the number is 100; use the Build layer tool in Build to establish a layered...

Embodiment 2

[0060]As attachedfigure 1 As shown, a simulation method of silica-coated calcium fluoride based on Materials Studio. In this embodiment, silica and calcium fluoride are used as the research object, which specifically includes the following steps:

[0061](1) Build initial models of silica and calcium fluoride;

[0062]Use the Visualizer interface in the Materials Studio software to build the molecular structure model of silica and calcium fluoride, and cut the constructed model. Among them, layer 1 and layer 3 of the model are silica, and two types can be obtained after cutting. Terminal surface: O terminal and Si-O, the O terminal surface is used as Model 3 layer 1 and layer 3, and the Si-O terminal surface is Model 4 layer 1 and layer 3, and the upper surface atom of layer 2 is F, and The number is 200, the lower surface atom is Ca, and the number is 100; use the Build layer tool in Build to establish a layered connection, and set a vacuum layer between the interfaces to obtain the sili...

Embodiment 3

[0078]As attachedfigure 1 As shown, a simulation method of silica-coated calcium fluoride based on Materials Studio. In this embodiment, silica and calcium fluoride are used as the research object, which specifically includes the following steps:

[0079](1) Build initial models of silica and calcium fluoride;

[0080]Use the Visualizer interface in the Materials Studio software to build the molecular structure model of silica and calcium fluoride, and cut the crystal plane of the constructed model. Among them, layer 1 and layer 3 of the model are silica, and two types can be obtained after cutting. Terminal surface: O terminal and Si-O. The surface of O terminal is used as layer 1 and layer 3 of Model 1, and the surface of Si-O terminal is used as layer 1 and layer 3 of Model 2. The upper surface atoms of layer 2 are F and Ca For the mixed surface, the number of F and Ca are both 100, and the number of atoms in the lower layer is F, and the number is 100; use the Build layer tool in Buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com