Layered mixing type feed raw material treatment device

A feed raw material and processing device technology, which is applied in the field of feed, can solve problems such as high requirements, damage to the nutritional content of finished feed, and complicated equipment installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

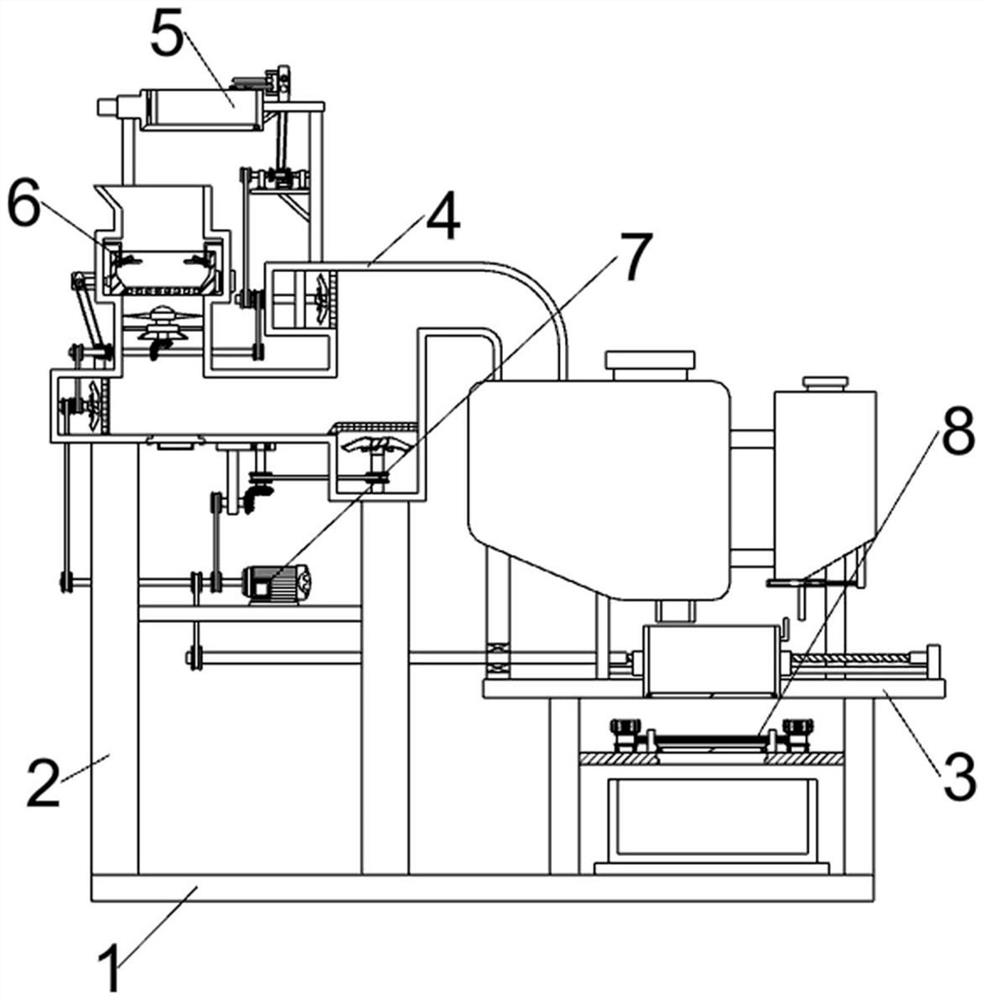

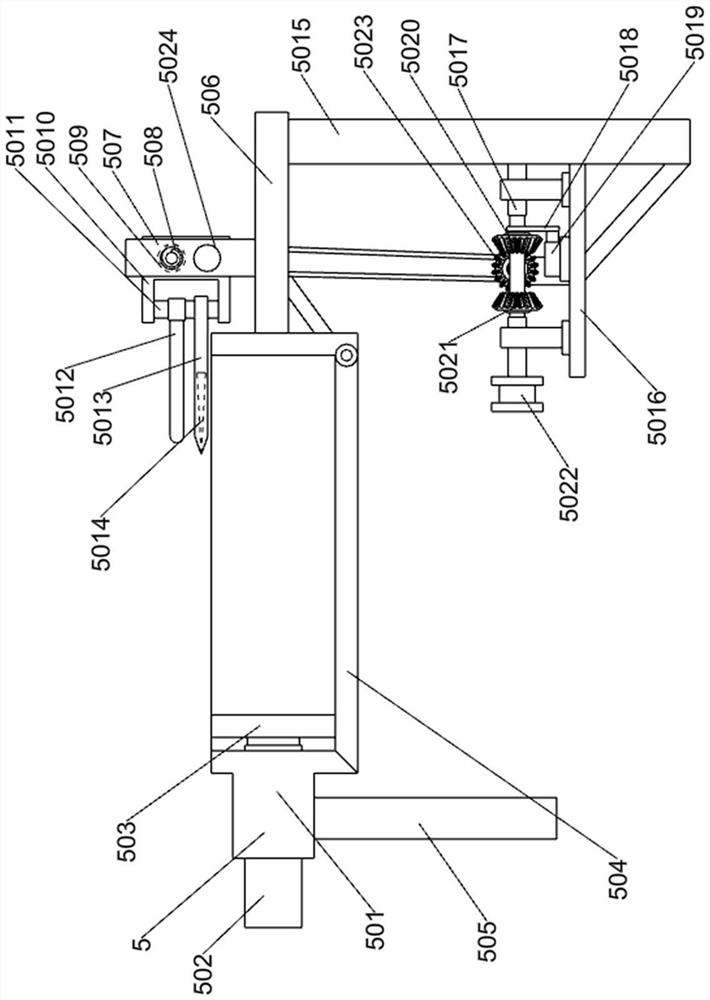

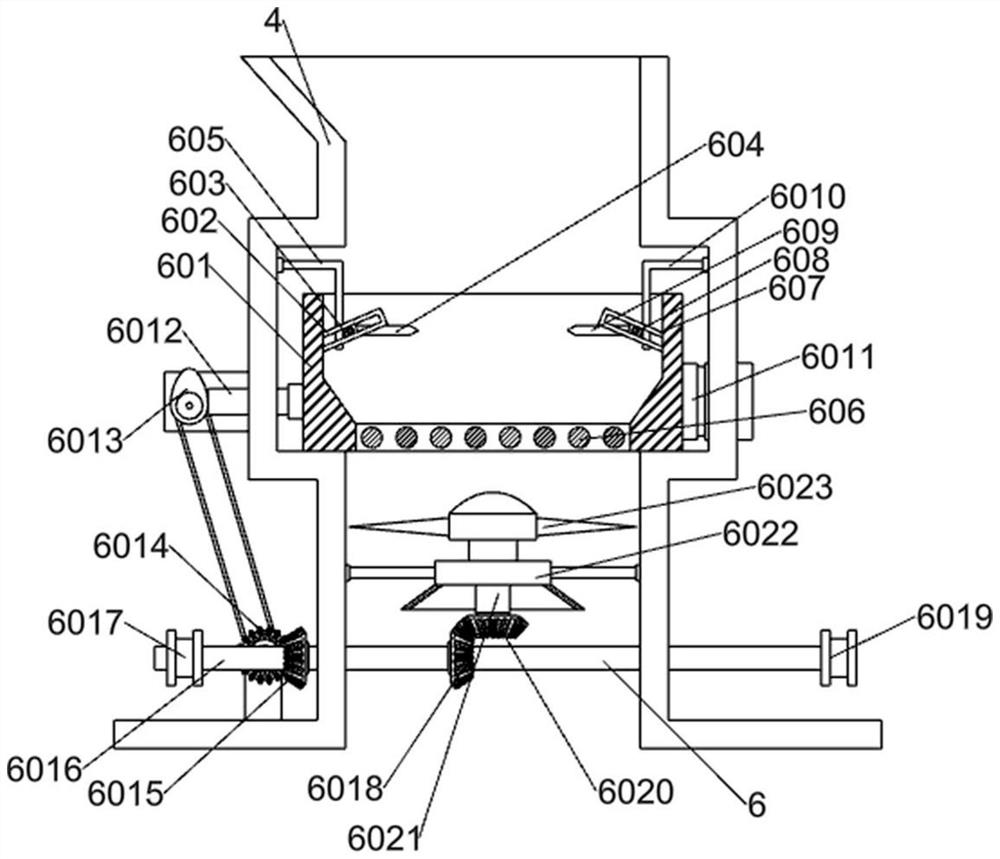

[0025] A layered mixed feed raw material processing device, such as Figure 1-5 As shown, it includes a connecting machine bottom plate 1, a first elevating leg 2, a working platform 3, a continuous processing cabin 4, a cover extraction mechanism 5, a split block decomposition mechanism 6, a screening mechanism 7, and a layered vibration combination mechanism 8; The upper part of the connecting machine bottom plate 1 is connected with the first elevated leg 2 and the working platform 3 in turn; the upper part of the connecting machine bottom plate 1 is connected with the layered vibration closing mechanism 8; the upper part of the first elevated leg 2 is connected with the continuous processing cabin 4; The first elevated leg 2 is connected with the miscellaneous screening mechanism 7; the miscellaneous screening mechanism 7 is connected with the continuous processing cabin 4; The 7 phases are connected; the upper part of the layered vibration combination mechanism 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com