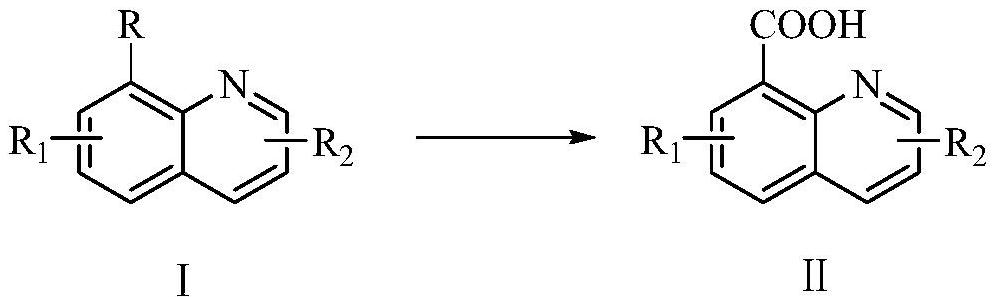

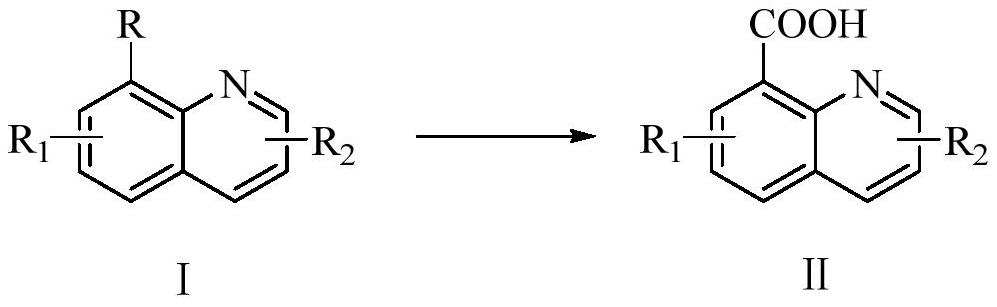

Method for preparing 8-quinoline carboxylic acid and derivatives of 8-quinoline carboxylic acid

A technology for quinoline carboxylic acid and derivatives, which is applied in the field of catalytic oxidation of quinoline derivatives to prepare 8-quinoline carboxylic acid and its derivatives, which can solve the problems of reducing production costs and achieve low production costs and high process safety , the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a 2L four-neck flask, add 150 g of 8-chloromethylquinoline, CoCl 2 ·6H 2 O 0.5g, AgCl 0.6g, CuCl 0.2g, acetonitrile-water (volume ratio 1:1) 800mL, start stirring, heat to reflux, start to feed oxygen slowly, the oxygen flow rate is 50mL / min, the reaction time is about 8h, stop feeding oxygen; distill under reduced pressure, evaporate at -0.095Mpa to a temperature of 90°C, cool down to room temperature in a water bath, add 150ml of water, stir well, filter, and distill the filtrate under reduced pressure to obtain a solid catalyst, which is recovered and used mechanically; 139.3 g of 8-quinolinic acid was obtained by drying, the content was 86%, and the yield was 81.5%.

Embodiment 2

[0019] In the 2L four-necked flask, add 8-methylquinoline 150g successively, Co(NO 3 ) 2 ·6H 2 O 0.4g, FeSO 4 0.8g, Cu(NO 3 ) 2 0.4g, 2-Methyltetrahydrofuran-water (volume ratio 2:1) 800mL, start stirring, heat to reflux, start to slowly pass in ozone, the flow rate of oxygen is 30mL / min, the reaction time is about 6.5h, stop the flow into ozone; vacuum distillation, -0.095Mpa steamed down to a temperature of 80°C, cooled to room temperature in a water bath, added 150ml of water, fully stirred, filtered, and the filtrate was distilled under reduced pressure to obtain a solid catalyst, which was recovered and used mechanically; the filter cake was dried to obtain 8- Quinolinic acid 144.6g, content 90%, yield 88.5%.

Embodiment 3

[0021] In a 2L four-neck flask, add 3,7-dichloro-8-chloromethylquinoline 150g, Co(OAc) 2 4H 2 O 0.2g, Na 2 WO 4 2H 2 O 0.5g, Cu(OAc) 2 ·H 2 O 0.5g, 800mL of chlorobenzene, start stirring, heat to 110°C, start to introduce ozone slowly, the flow rate of oxygen to be introduced is 25mL / min, the reaction time is about 8h, stop introducing ozone; distill under reduced pressure, cool to room temperature in water bath , filtered, and the filtrate was distilled under reduced pressure to obtain a solid catalyst, which was recovered and used mechanically; the filter cake was dried to obtain 117.2 g of 3,7-dichloro-8-quinolinic acid, with a content of 92% and a yield of 90.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com