Energy-saving environment-friendly biogel fracturing fluid and preparation method thereof

An energy-saving and environmentally friendly bio-glue technology, which is applied to drilling compositions, production fluids, wellbore/well components, etc., can solve problems such as high prices, limited production of guar gum, damage to reservoirs, etc., and achieve stable escape routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

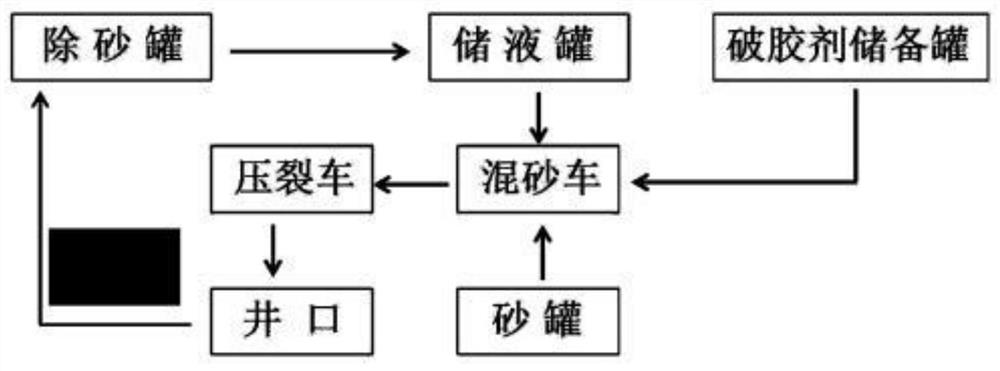

[0046] A preparation method of the above-mentioned energy-saving and environment-friendly bio-rubber fracturing fluid, comprising the following preparation process:

[0047] (1) Adding a water quality conditioner to clear water or flowback liquid, and then flushing and releasing evenly to obtain activated water, wherein the weight of the water quality conditioner is 0.02 to 0.05wt% of the water;

[0048] (2) Add bio-thickener to the activated water, the weight of bio-thickener is 1.5-2.5% of the activated water;

[0049] (3) Add granular solid proppant, and then add bio-gel breaker to obtain energy-saving and environment-friendly bio-rubber fracturing fluid.

[0050] Preferably, after adding the breaker, optionally add thiosulfate.

[0051] Preferably, the above preparation processes are all carried out at room temperature.

[0052] Preferably, the above preparation process can be carried out cyclically.

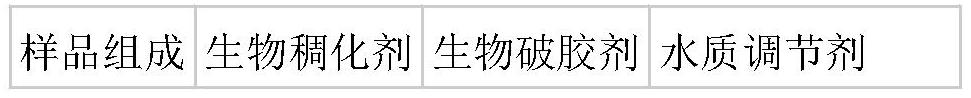

[0053] In the fracturing fluid of Examples 1-4, the composition form...

Embodiment 1

[0058] A method for preparing an energy-saving and environment-friendly bio-rubber fracturing fluid, comprising the following preparation process:

[0059] The weight fraction of raw materials is: 100 parts of gel breaker, 5 parts of thickener and 5 parts of regulator.

[0060] (1) Adding a regulating agent to clear water or flowback liquid, and then flushing and releasing evenly to obtain activated water, wherein the weight of the regulating agent is 0.03wt% of the water;

[0061] (2) adding a thickener in the activated water, the weight of the thickener is 2% of the activated water;

[0062] (3) Add sand and then add gel breaker to obtain energy-saving and environment-friendly bio-rubber fracturing fluid.

Embodiment 2

[0064] A method for preparing an energy-saving and environment-friendly bio-rubber fracturing fluid, comprising the following preparation process:

[0065] The weight fraction of raw materials is: 100 parts of gel breaker, 10 parts of thickener and 10 parts of regulator.

[0066] (1) Adding a regulating agent to clear water or flowback liquid, and then flushing and releasing evenly to obtain activated water, wherein the weight of the regulating agent is 0.03wt% of the water;

[0067] (2) adding a thickener in the activated water, the weight of the thickener is 2% of the activated water;

[0068] (3) Add sand and then add gel breaker to obtain energy-saving and environment-friendly bio-rubber fracturing fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com