Dyeing and finishing process of cold-feeling tencel linen

A technology of tencel and cold feeling, which is applied in the field of textile fabric production, can solve the problems of hard ramie fiber, affect the quality of dyeing and finishing, and incomplete combustion, so as to reduce damage, improve the effect of smoothness, and avoid damage and burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

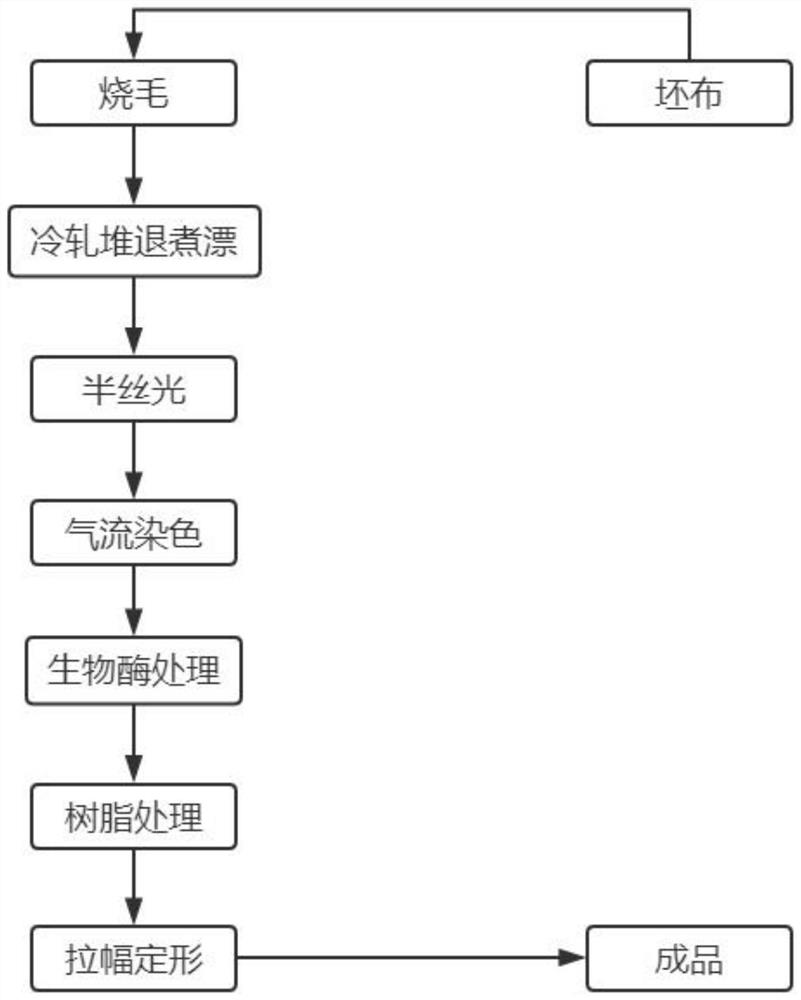

[0046] see figure 1 , a kind of dyeing and finishing process of cold-sense tencel hemp, comprising the following steps:

[0047] S1, select the fabric that adopts ordinary tencel ply yarn as warp yarn and ramie single yarn as weft yarn to interweave, and carry out gray cloth inspection;

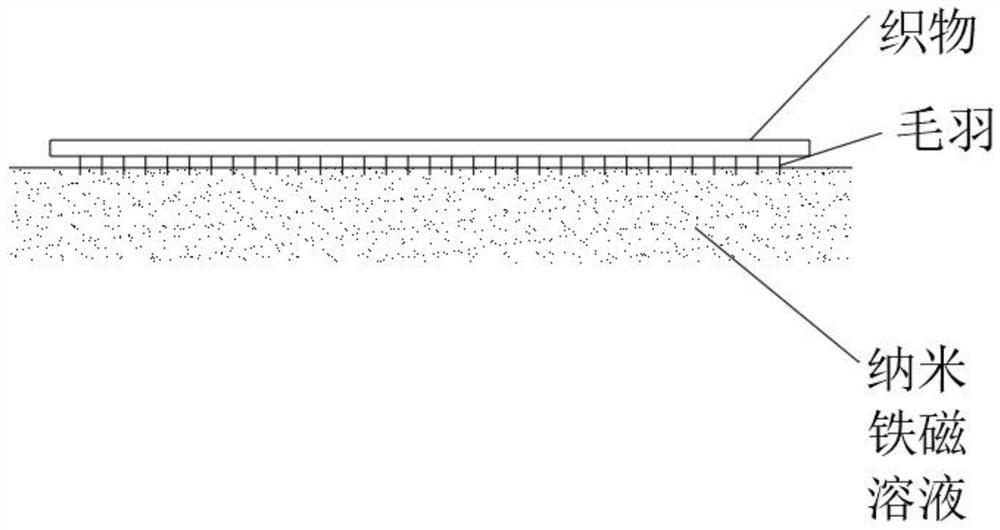

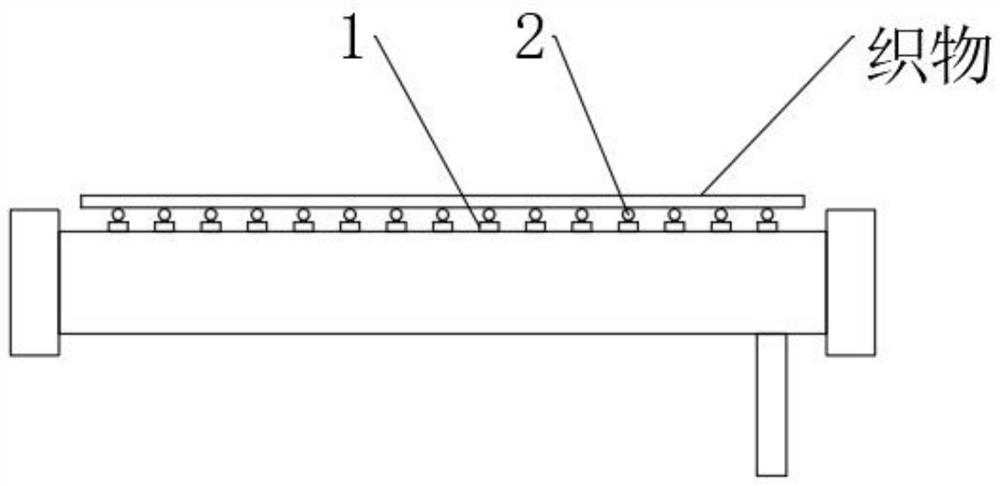

[0048] S2. Adopt a gas singeing machine with two positive and two negative burners, a temperature of 800°C, a vehicle speed of 100m / min, and a singeing grade of 4. The fabric burns off irregular hairs by contacting with a hot magnetic rod;

[0049] S3. Adopt the one-step method of cold pad-batch descouring and bleaching. First, the fabric is soaked in the working solution (3 grids), then rolled up and sealed with a plastic film, and rotated at room temperature at 8r / min for 20h, and the end Then wash with 2 grids of hot water, then steam with 4 grids, and finally wash with 4 grids of hot water, 2 grids of warm water and 2 grids of cold water;

[0050] S4, the fabric is treated by semi-merce...

Embodiment 2

[0066] see figure 1 , a kind of dyeing and finishing process of cold-sense tencel hemp, comprising the following steps:

[0067] S1, select the fabric that adopts ordinary tencel ply yarn as warp yarn and ramie single yarn as weft yarn to interweave, and carry out gray cloth inspection;

[0068] S2. Adopt a gas singeing machine with two positive and two negative burners, a temperature of 850°C, a vehicle speed of 140m / min, and a singeing grade of 4. The fabric burns off irregular hairs by contacting with a hot magnetic rod;

[0069] S3. Using the one-step method of cold pad-batch descouring and bleaching, first pad the fabric with the working solution (3 grids), then roll it up and seal it with a plastic film, and carry out 9r / min rotating cold-batch at room temperature for 22h, and end Then wash with 2 grids of hot water, then steam with 4 grids, and finally wash with 4 grids of hot water, 2 grids of warm water and 2 grids of cold water;

[0070] S4, the fabric is treated b...

Embodiment 3

[0078] see figure 1 , a kind of dyeing and finishing process of cold-sense tencel hemp, comprising the following steps:

[0079] S1, select the fabric that adopts ordinary tencel ply yarn as warp yarn and ramie single yarn as weft yarn to interweave, and carry out gray cloth inspection;

[0080] S2. A gas singeing machine is adopted, with two positive and two negative burners, a temperature of 900°C, a vehicle speed of 180m / min, and a singeing grade of 4. The fabric burns off irregular hairs by contacting with a hot magnetic rod;

[0081]S3. Adopt the one-step method of cold pad-batch descouring and bleaching. First, the fabric is soaked in the working solution (3 grids), then rolled up and sealed with plastic film, and rotated at room temperature at 10r / min for 24 hours. Then wash with 2 grids of hot water, then steam with 4 grids, and finally wash with 4 grids of hot water, 2 grids of warm water and 2 grids of cold water;

[0082] S4, the fabric is treated by semi-merceriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com