Intelligent manufacturing control system for whole solar cell factory

A solar cell, intelligent manufacturing technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of labor, inconvenience, workshop beauty discount, etc., achieve easy standardized design, improve test efficiency, reduce line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

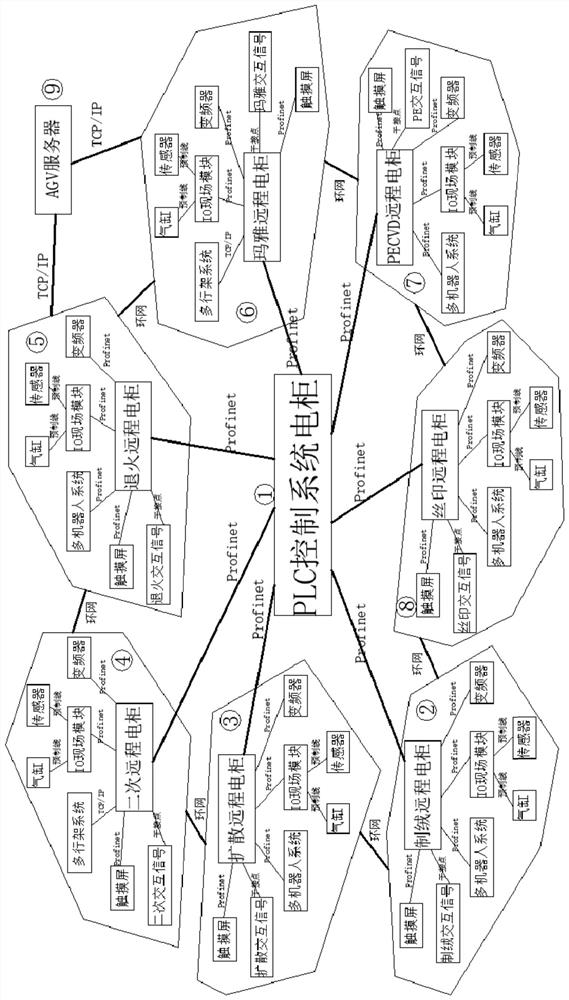

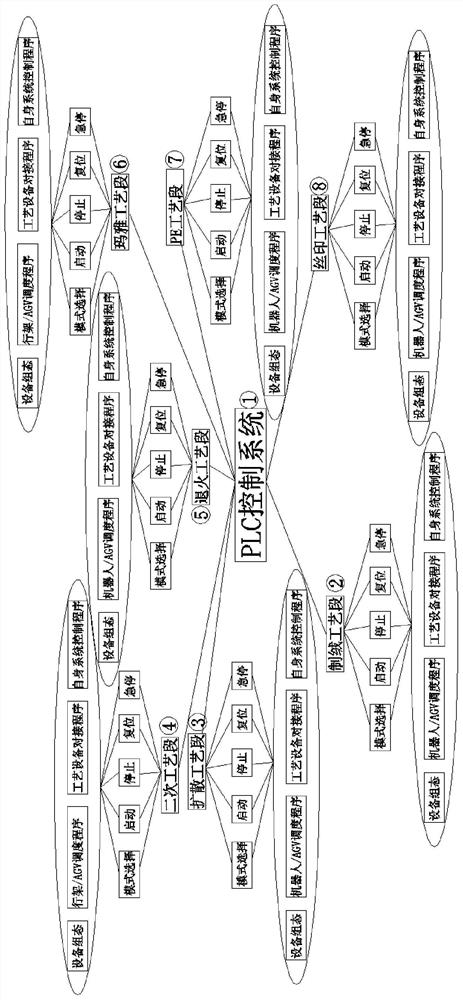

[0021] Such as figure 1 and figure 2 As shown, the solar battery whole factory intelligent manufacturing control system of this embodiment includes a control unit, an AGV unit and a plurality of control stations. Secondary cleaning control station, diffusion control station, Maya control station, PECVD control station and silk screen control station; each control station is an independent control station with independent power supply, and each control station is connected to each other and connected to the control unit to form a Ring network; the AGV unit is connected to the ring network, and the control unit controls the AGV trolley in the AGV unit to perform reclaiming and feeding operations between each process section. The ring network refers to the interconnection of the entire communication system to form a circle. When there is a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com