Preparation process and system of o-chlorobenzonitrile

A technology of o-chlorobenzonitrile and preparation process, which is applied in the preparation of halogenated hydrocarbons, the preparation of hydrocarbon ammoxidation, the purification/separation of carboxylic acid nitrile, etc., can solve problems such as potential safety hazards, temperature rise, pressure increase, etc., and achieve the effect of avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

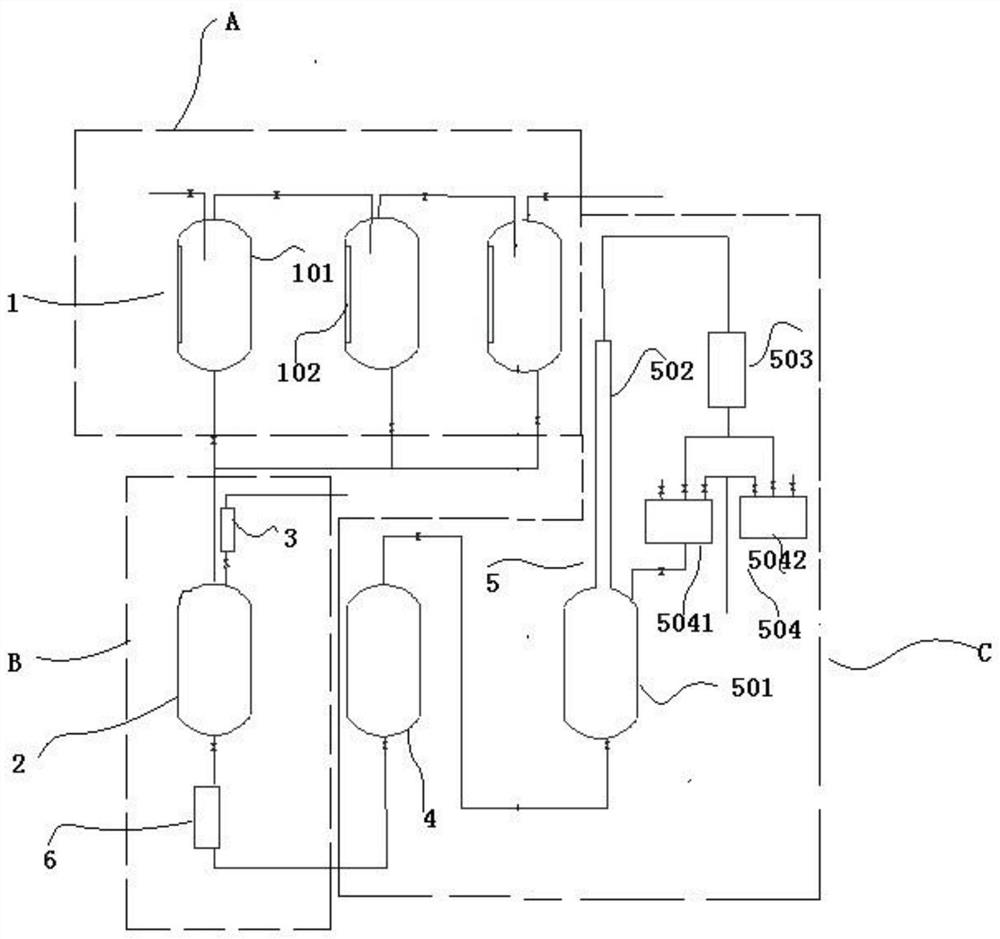

[0049] Embodiment 1 is the system that prepares o-chlorobenzonitrile with o-chlorobenzonitrile as raw material

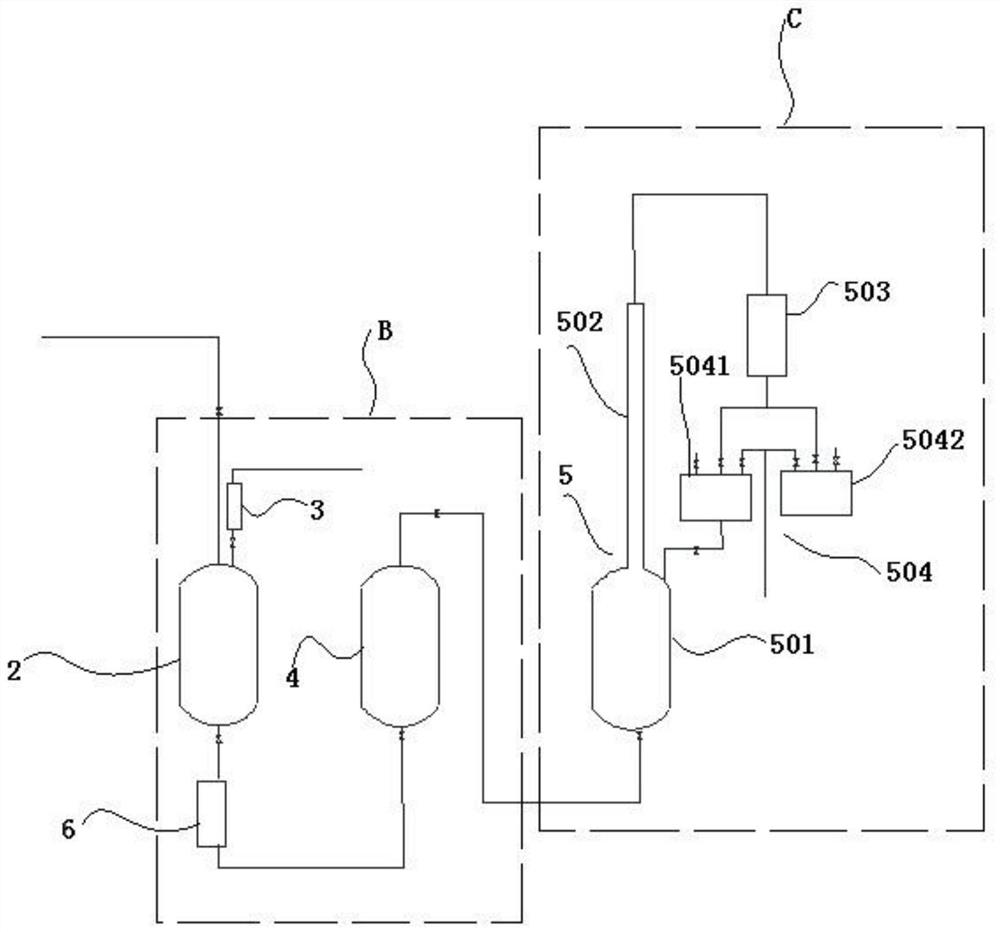

[0050] Including: sequentially connected ammoniation unit (B) and purification unit (C), the ammoniation unit (B) can realize the ammoniation reaction of o-chlorotrichlorotoluene, and the purification unit washes and distills the crude product obtained from the ammoniation reaction After the product is obtained, the ammoniation unit (B) is connected with the purification unit (C), and the crude product obtained in the ammoniation reaction can be transported to the purification unit (C) for processing, and the conventional reaction device and connection device in the art can be used to achieve the purpose .

[0051] In this embodiment, the ammoniation unit (B) includes an ammoniation reaction tank (2), and the purification unit (C) includes a water washing tank (4) and a distillation unit (5) connected in sequence, and the distillation unit (5) ) includes a distilla...

Embodiment 2

[0055] Embodiment 2 is the system that prepares o-chlorobenzonitrile with o-chlorotoluene as raw material

[0056] In this embodiment, on the basis of Embodiment 1, a chlorination unit (A) is connected before the ammoniation unit.

[0057]For realizing continuous uninterrupted reaction, in this implementation, described chlorination unit (A) comprises three chlorination stills (1) connected in series, and each described chlorination still (1) is connected with described ammoniation unit ( B) Connection, specifically in this embodiment, connection with the ammoniation reactor (1) in the ammoniation unit (B).

[0058] Each said chlorination kettle (1) comprises a chlorination reactor body (101) and an ultraviolet lamp (102) located in the said chlorination reactor body (101), so that in the chlorination reactor (1) A photocatalytic chlorination reaction is carried out.

[0059] The ultraviolet lamp includes an ultraviolet light source and a quartz ultraviolet lamp shell arrang...

Embodiment 3

[0060] Embodiment 3 is the system that prepares o-chlorobenzonitrile with o-chlorotoluene as raw material

[0061] The ultraviolet lamp of chlorination kettle in embodiment 2 is replaced with 400W high-pressure mercury lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com