Preparation method, printing method and application of 4D printing intelligent hydrogel

A hydrogel, intelligent technology, applied in biochemical equipment and methods, applications, household appliances, etc., can solve the problems of slow response to external stimuli, poor biocompatibility, intricate rheological characterization, etc., and achieve good printability. , good adhesion, good 4D deformation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

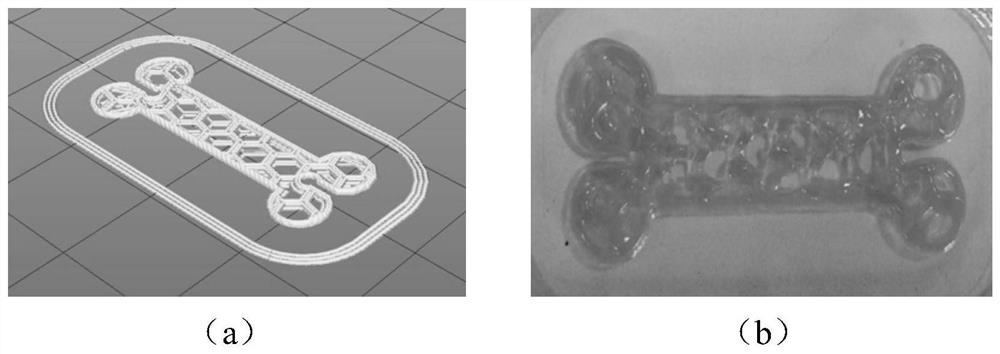

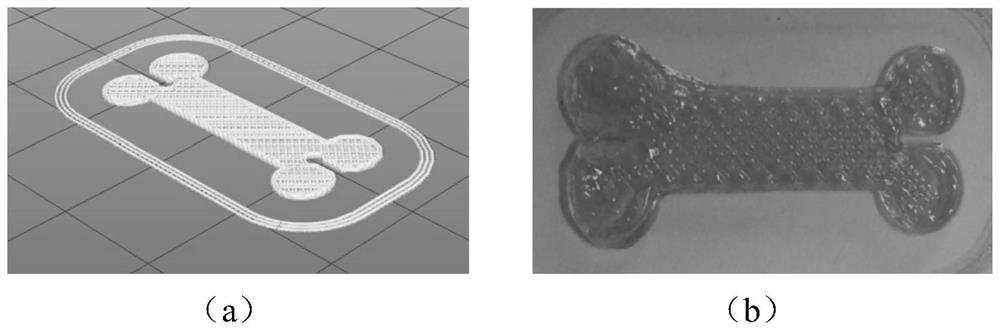

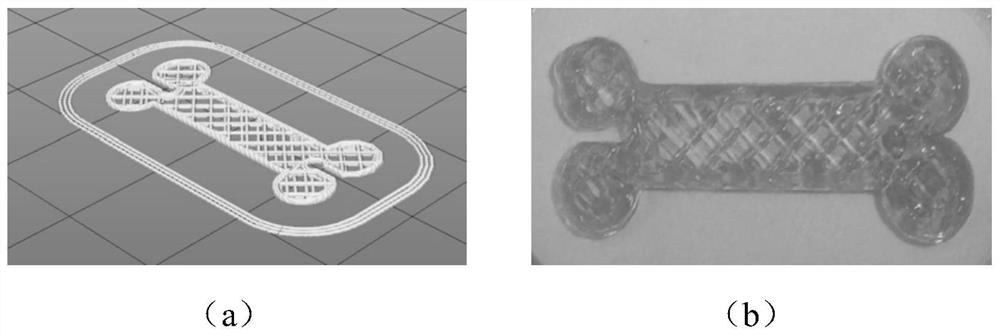

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of 4D printed smart hydrogel

[0032] Add 40 g of cellulose nanofibers (NFC), 2 g of N,N-dimethylacrylamide, 0.1 g of photoinitiator Irgacure 2959, 0.1 g of glucose oxidase, 1 g of glucose, and 4g of endothelial cell growth factor (ECGF) at 200μg / ml and 2g of heparin at a concentration of 20μg / ml were uniformly mixed and reacted, placed in an open mechanical stirring device, and nitrogen was introduced for protection; Slowly add 2g of magnesium lithium silicate, use 10g of deionized water to rinse the feeding caliber of the three-necked flask, and flush the material attached to the mouth of the three-necked flask into the three-necked flask; take out the three-necked flask, and react at room temperature for 0.5h to obtain the target material 4D printing smart hydrogels.

Embodiment 2

[0033] Example 2 Preparation of 4D printed smart hydrogel

[0034] Add 50 g of cellulose nanofibers (NFC), 3 g of N,N-dimethylacrylamide, 0.1 g of photoinitiator Irgacure 2959, 0.1 g of glucose oxidase, 1.5 g of glucose, and Concentration of 4g of endothelial cell growth factor (ECGF) of 200μg / ml and concentration of 20μg / ml of 2g of heparin, mixed evenly and reacted, placed in an open mechanical stirring device, fed with nitrogen for protection; Slowly add 2.5g lithium magnesium silicate once, use 10g deionized water to rinse the feeding aperture of the three-necked flask, and flush the material attached to the mouth of the three-necked flask into the three-necked flask; take out the three-necked flask, and react at room temperature for 0.5h to obtain Target material 4D printing smart hydrogel.

Embodiment 3

[0035] Example 3 Preparation of 4D printed smart hydrogel

[0036] 50 g of cellulose nanofibers (NFC), 4 g of N,N-dimethylacrylamide, 0.1 g of photoinitiator Irgacure 2959, 0.1 g of glucose oxidase, 1.5 g of glucose, and 200 μg / ml 4g of endothelial cell growth factor (ECGF) and 2g of heparin with a concentration of 20μg / ml were uniformly mixed and reacted, placed in an open mechanical stirring device, and nitrogen was passed into the protection; then 4g of silicic acid was slowly added to the three-necked flask three times For magnesium and lithium, use 10g of deionized water to rinse the feeding caliber of the three-necked flask, and pour the substance attached to the mouth of the three-necked flask into the three-necked flask; take out the three-necked flask, and react at room temperature for 0.5h to obtain the target material 4D printing intelligent hydrogel glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com