A processing technology of 5050 aluminum alloy

A processing technology and technology for aluminum alloys, applied in the field of aluminum alloys, can solve problems such as affecting the uniformity of oxidation and restricting applications, and achieve the effects of poor equipment versatility, improved selectivity, and reduced processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

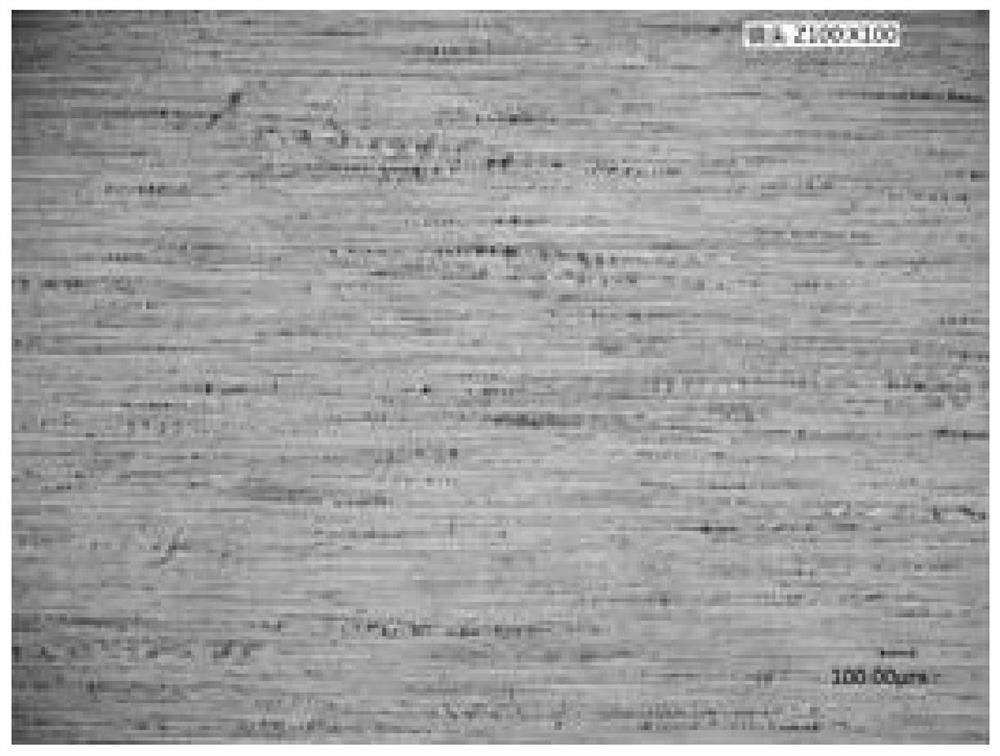

Image

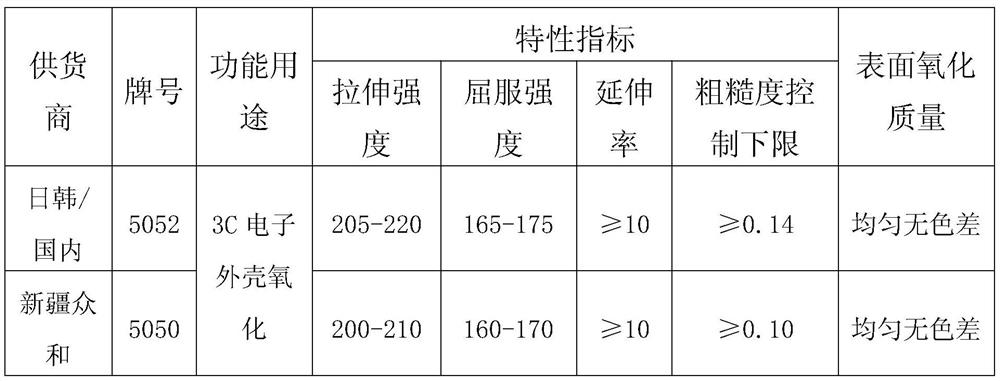

Examples

Embodiment 1

[0075] The specific operation steps are as follows:

[0076] (1) Use 1080 pure aluminum liquid with an Fe content of 0.07-0.10% for ingot casting, and the Mg content control target is 1.5-1.8%;

[0077] After the ingot is milled, homogenization annealing is carried out, and the heat preservation is carried out at 500°C for 12 hours.

[0078] (2) Hot rolling: the homogenized annealed ingot is rolled at a low temperature of 460-480°C for a total of 23 passes.

[0079]When performing hot processing with 23 passes of hot rolling, in the 1st to 4th passes, the absolute reduction in a single pass is ≤ 15mm, and the processing technology setting is carried out with the absolute reduction gradually increasing; from the 5th to the 4th 16 passes, adopt the absolute reduction of no more than 30mm to set up the thermal processing process; under the premise that the temperature of the ingot is ≥ 400°C, complete the cutting of the head and tail of the ingot; design the cutting head based o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com