Power supply filter with high-efficiency electromagnetic isolation and heat dissipation functions

A power filter and electromagnetic isolation technology, which is applied to the circuit layout on the support structure, electrical components, magnetic field/electric field shielding, etc., can solve the problem of easy loosening and damage of inductors, non-targeted setting of insulating substrates, and breakdown of filter circuits Damage and other problems, to avoid voltage breakdown short circuit problem, good electromagnetic shielding effect, high stability welding connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

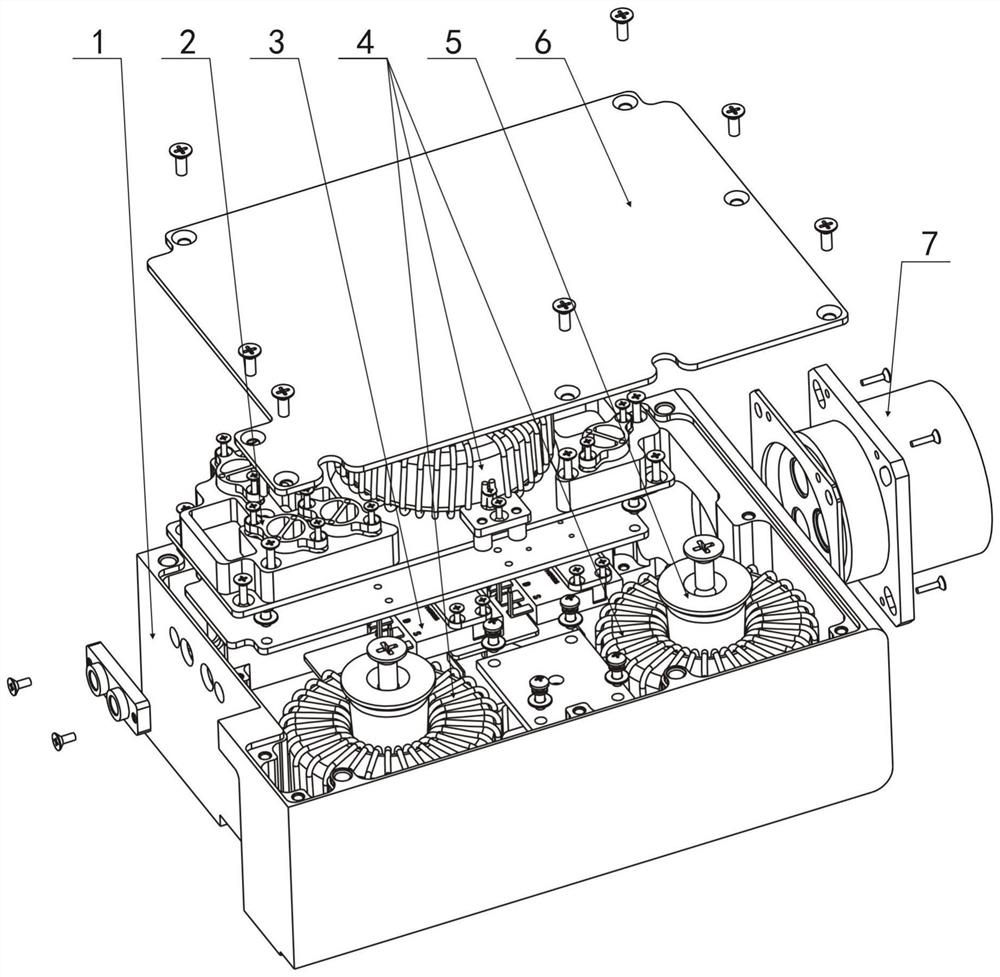

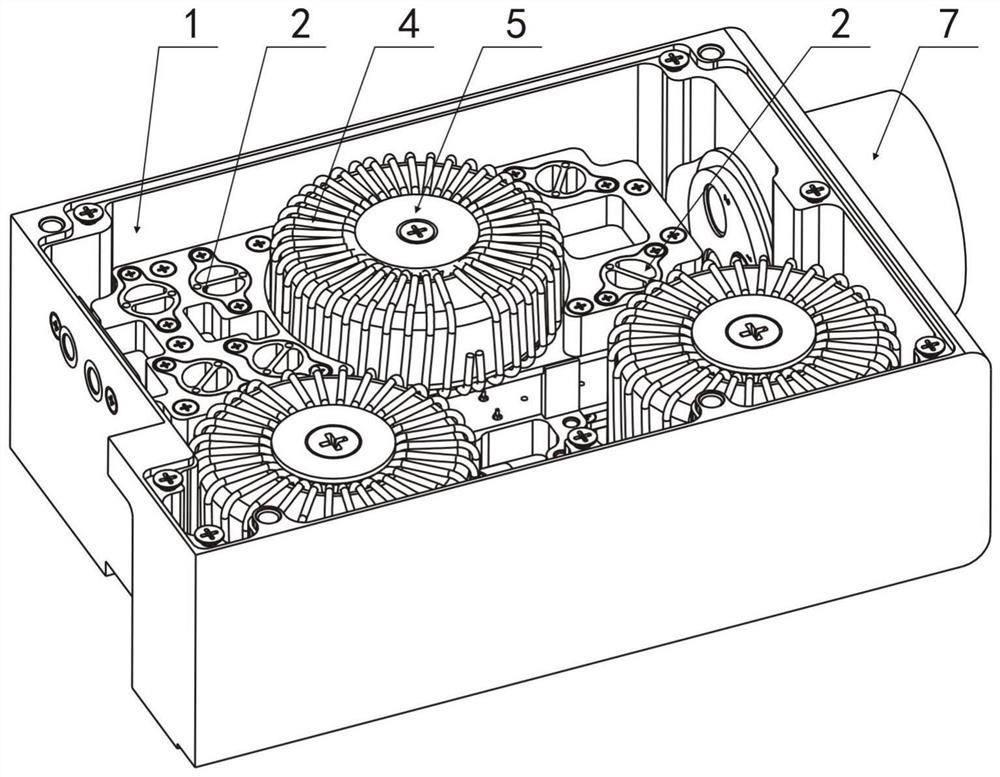

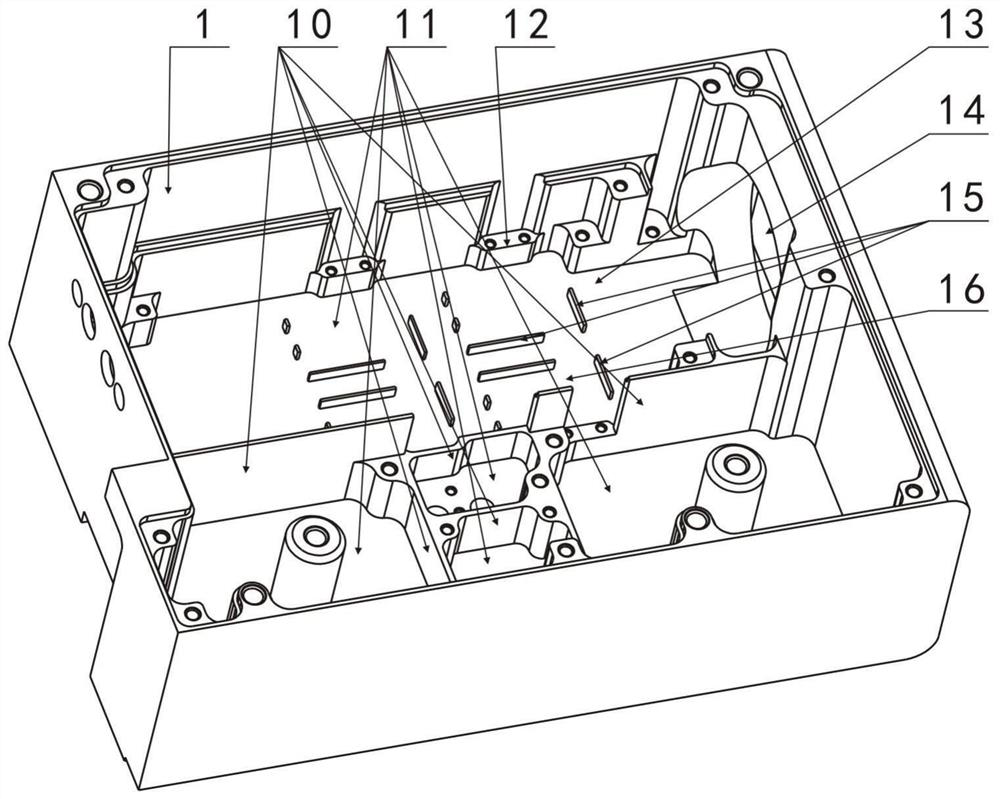

[0041] The present invention will be further described below in conjunction with accompanying drawing:

[0042] Such as Figure 1-Figure 7 As shown, the power filter with high-efficiency electromagnetic isolation and high-efficiency heat dissipation functions of the present invention includes a housing 1 and a filter circuit ( Figure 1-Figure 12 The circuit diagram is not shown in the figure), the filter circuit includes interconnected heating devices 31 and annular inductance 4, and the power supply filter also includes a heat sink for cooling the heating devices 31, and is used to weld a plurality of lead wires Connected lead wire welding device 2 and inductance installation device 5 for installing inductance, housing 1 is provided with a plurality of partitions (see the vertical partition 10 and transverse partition 18 in the figure) that are isolated from each other and used to install different The independent inner cavity 11 of the independent device, the heat dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com