Energy-saving and environment-friendly iron-removing stone powder recycling, granulating and processing technology

A technology of energy saving, environmental protection and processing technology, which can be used in manufacturing tools, metal processing equipment, methods of granulating raw materials, etc., and can solve problems such as flying dust, poor working environment, and environmental dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

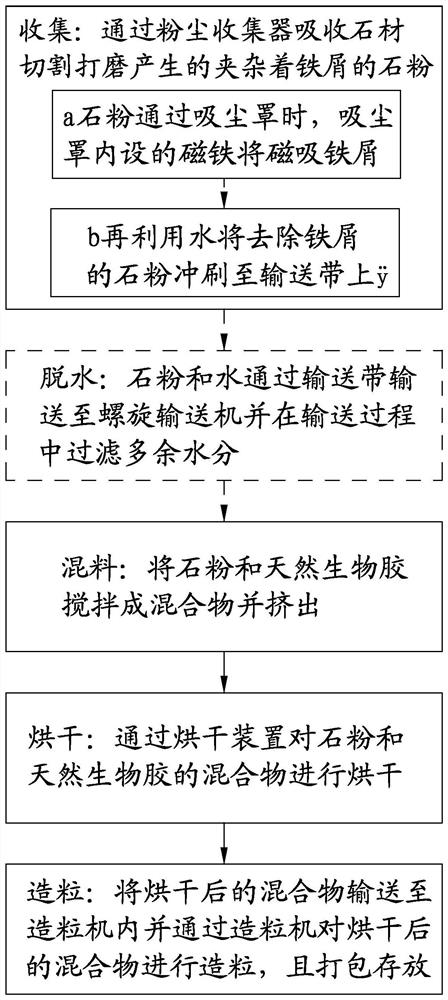

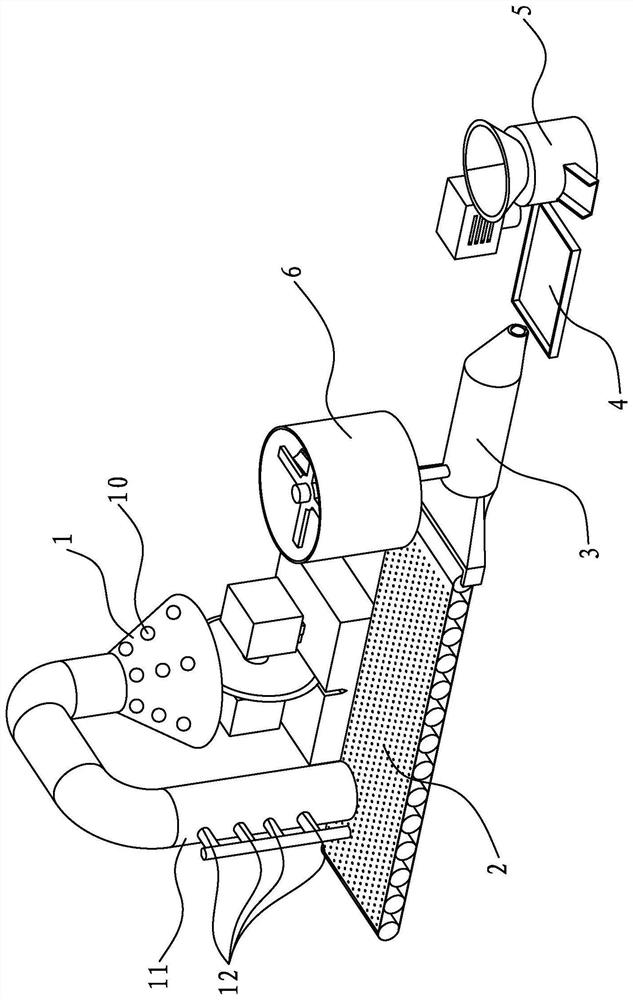

[0029] see figure 1 , figure 2 , the present invention discloses an energy-saving and environment-friendly recycling and granulation process for iron-removing stone powder, which has the following steps:

[0030] (1) Collection: absorb the stone powder mixed with iron filings generated by stone cutting and grinding through the dust collector;

[0031] a When the stone powder passes through the dust-absorbing hood 1, the magnet 10 in the dust-absorbing hood will magnetically attract the iron filings;

[0032] B and then use water to wash away the stone powder from the iron filings to the conveyor belt 2;

[0033] (2), material mixing: stone powder and natural bio-glue are respectively added in the screw conveyor 3 for conveying, stirring into a mixture and extruding;

[0034] (3), drying: dry the stone powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com