High-speed, high-resolution and high-precision ultra-high temperature molten pool temperature field online monitoring device and method

A monitoring device and high-resolution technology are applied in the online monitoring device for high-speed, high-resolution, high-precision, ultra-high temperature molten pool temperature field, and in the field of online monitoring of molten pool temperature field in the process of additive manufacturing laser selective melting process, which can solve the problem of inability to measure the temperature field. Problems such as the distribution of molten pool temperature values, to avoid inaccurate synchronization trigger time, easy to implement, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

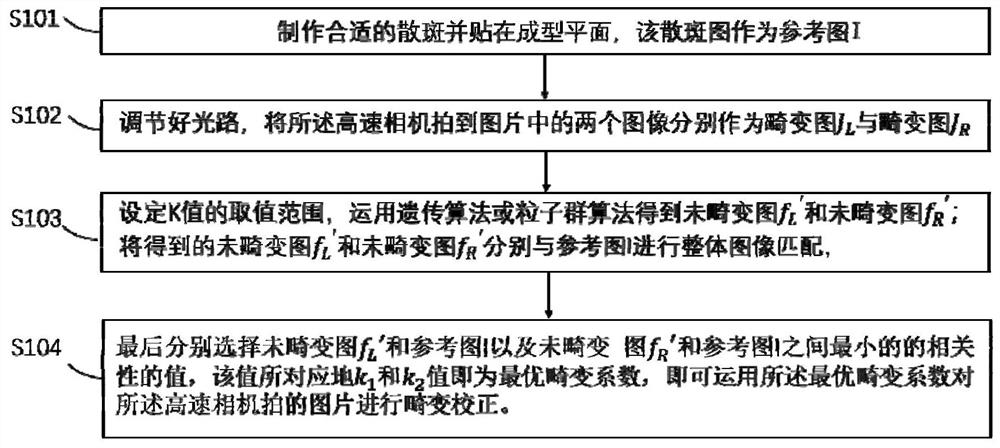

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples.

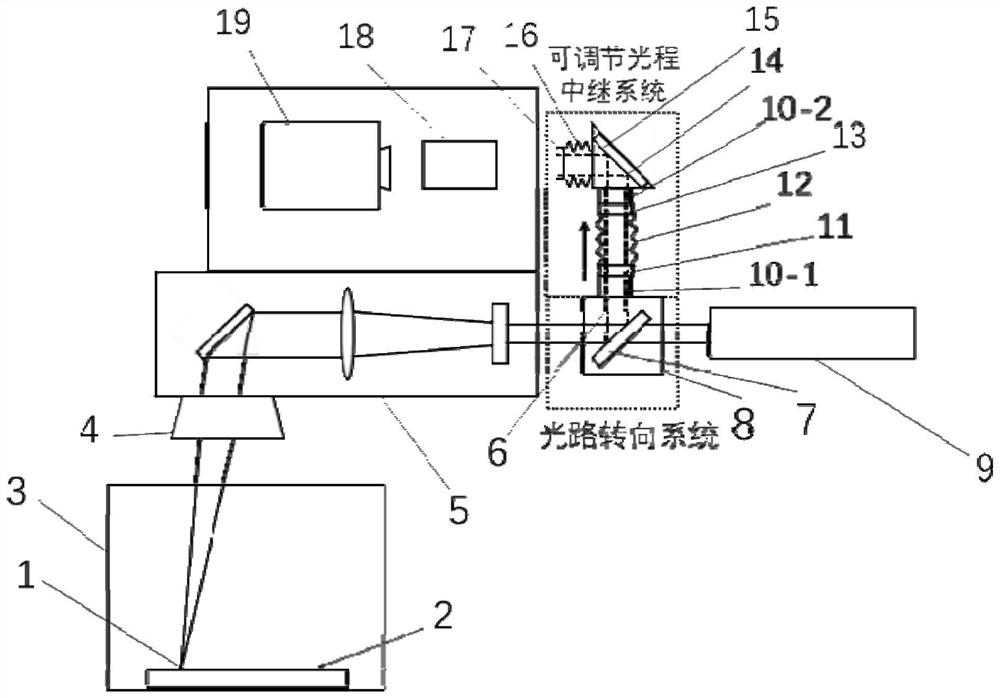

[0049] The invention provides a high-speed, high-resolution and high-precision ultra-high temperature molten pool temperature field on-line monitoring device, such as figure 1 As shown, it includes a laser 9, a scanning vibrating mirror 5, a focusing lens 4, a long-wave pass dichroic mirror 7, a light splitting system 18, a high-speed camera 19 and a computer 25; wherein, the long-wave passing dichroic mirror 7 is located between the laser 9 and the scanning vibrating Between mirrors 5.

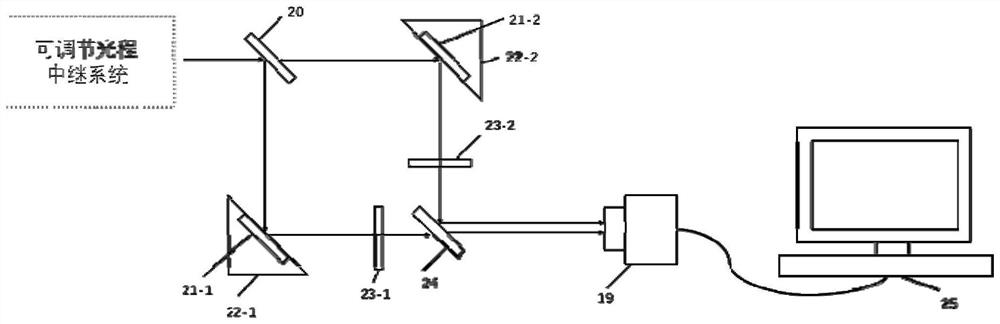

[0050] The laser light emitted by the laser 9 is irradiated on the molten pool 1 in the printing chamber 3 through the long-wave pass dichroic mirror 7, the scanning galvanometer 5, and the focusing lens 4; It is reflected by the long-wave pass dichroic mirror 7 and enters the spectroscopic system 18; the spectroscopic system divides the infrared light of the melting poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com