Lead plaster containing conductive agent and lead-acid storage battery

A lead-acid battery and conductive agent technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve problems such as consumption and oxidation, and achieve the effects of large process current, increased capacity, and stable and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

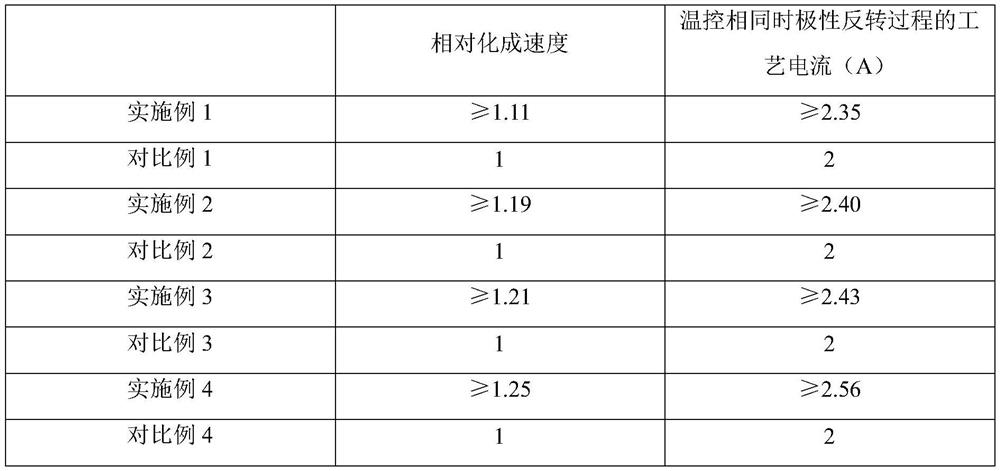

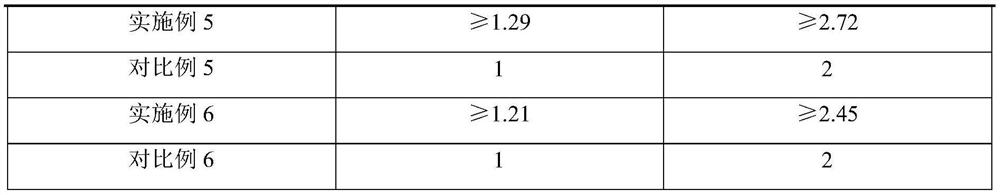

Examples

Embodiment 1

[0052]In this example, the positive and negative lead paste of the lead-acid battery, the mass parts of each component of the lead paste are 100 parts of lead powder, 1 part of lead-tin 1wt.% alloy powder, 0.8 part of barium sulfate, 10 parts of dilute sulfuric acid, and 8.5 parts of ionized water. Among them, the lead-tin 1wt.% alloy means that the mass proportion of tin contained in the lead-tin alloy is 1%, and the following are similar.

[0053]The lead powder is ball milled lead powder with an oxidation degree of 75%; optionally, the lead powder may also be lead oxide with a degree of oxidation of 100%.

[0054]The method for preparing the positive and negative lead pastes of the present embodiment includes the following steps: weigh each component according to the above-mentioned lead paste formula, and add lead powder, lead-tin 1wt.% alloy powder, and barium sulfate into the paste machine Stir for 5 minutes, mix well, quickly add deionized water, stir for 5 minutes, then slowly add...

Embodiment 2

[0056]The difference from Example 1 is that the positive and negative lead pastes of the lead-acid battery of this example are composed of 100 parts of lead powder, 2 parts of lead-samarium 0.3wt.% alloy powder, and barium sulfate. 0.8 parts, 10 parts dilute sulfuric acid, 8.5 parts deionized water.

Embodiment 3

[0058]The difference from Example 1 is that the lead-acid battery positive and negative lead pastes of this example contain 100 parts by mass of lead powder and 0.5wt.% lead-lanthanum-tin 1wt.% alloy powder. 3 parts, 0.8 parts of barium sulfate, 10 parts of dilute sulfuric acid, 8.5 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com