Oil-water separation pipe with hydrophobic and oleophylic surface and preparation method and application thereof

A technology of oil-water separation, hydrophobic and lipophilic, which is applied in separation methods, immiscible liquid separation, liquid separation, etc. It can solve the problems of inability to efficiently and quickly treat emulsified oily wastewater, fewer separation cycles, and continuous separation. Low cost, low price, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Mix the PDMS pre-polymerization solution and the initiator Dow Corning 184 at a mass ratio of 10:1, discharge the air bubbles, pour it into an empty groove of 10cm*6cm*1cm, put it in an oven, and cure it at 80°C for 4 hours to obtain PDMS flakes;

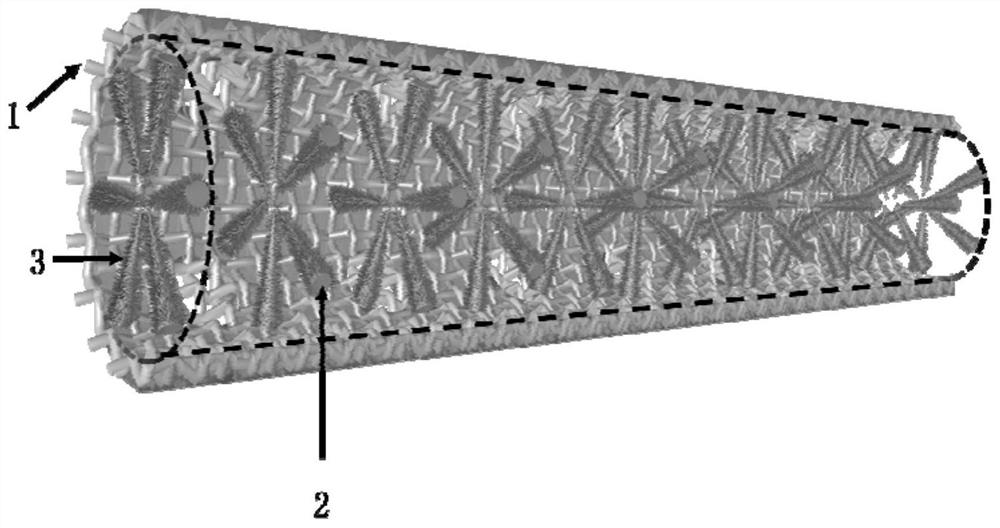

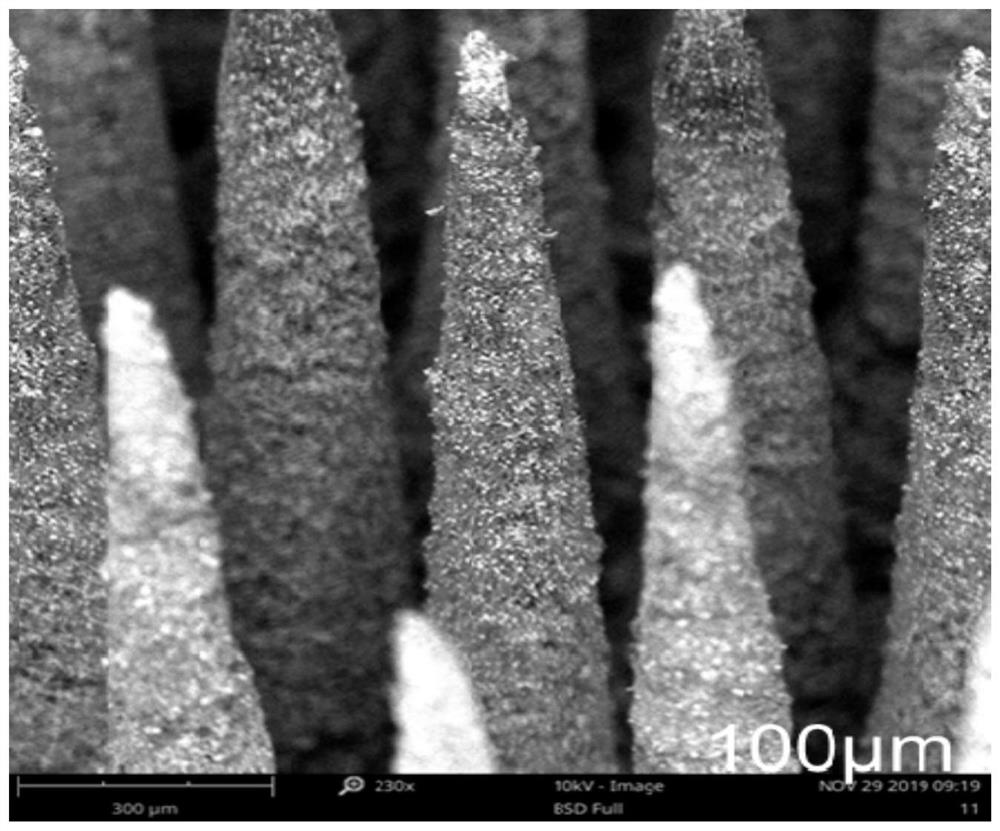

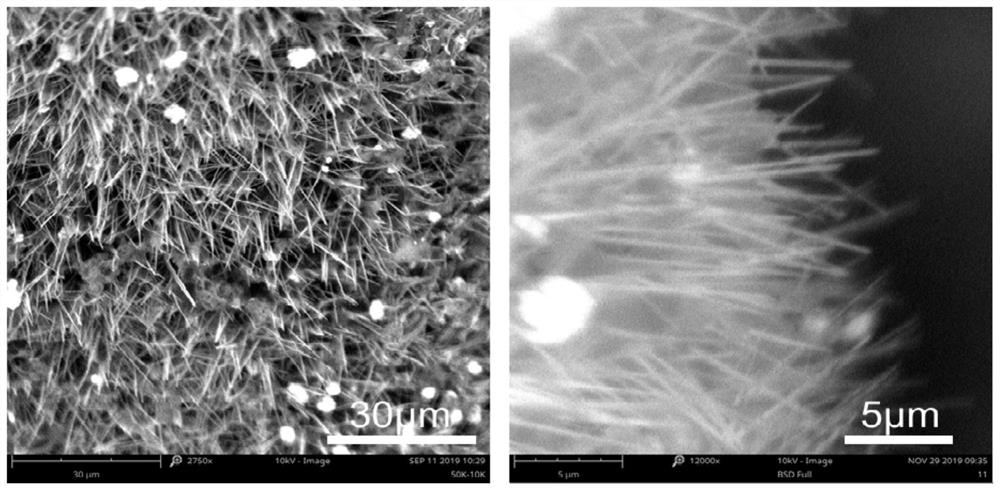

[0059] (2) with CO 2 A type laser punches holes on the PDMS sheet obtained in step (1), the laser power is set to 80%, and repeats twice; the diameter of a single laser spot is set to 0.3 millimeters, and the distance between the laser spots is 0.6 millimeters, which are staggered along the long axis Cloth, long axis 80 millimeters, short axis 19 millimeters arrayed tapered hole matrix; made polydimethylsiloxane template with arrayed tapered holes;

[0060] (3) Preparation of epoxy resin glue: select commercially available epoxy resin glue, for example, Kangda New Material Company, including A and B two tubes, A tube is epoxy resin, B tube is curing agent; A tube, B tube Mix the glue evenly with a mass ratio of 1:1.

...

Embodiment 2

[0068] (1) Mix the PDMS pre-polymerization solution and the initiator Dow Corning 184 at a mass ratio of 10:1, discharge the air bubbles, pour it into an empty groove of 10cm*6cm*1cm, put it in an oven, and cure it at 80°C for 4 hours to obtain PDMS flakes;

[0069] (2) with CO 2 A type laser punches holes on the PDMS sheet obtained in step (1), the laser power is set to 60%, and repeats twice; the diameter of a single laser spot is set to 0.3 millimeters, and the distance between the laser spots is 1.5 millimeters, which are staggered along the long axis Cloth, long axis 80 millimeters, short axis 19 millimeters arrayed tapered hole matrix; made polydimethylsiloxane template with arrayed tapered holes;

[0070] (3) Preparation of epoxy resin glue: select commercially available epoxy resin glue, for example, Kangda New Material Company, including A and B two tubes, A tube is epoxy resin, B tube is curing agent; A tube, B tube Mix the glue evenly with a mass ratio of 1:1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com