Barium-barium-tantalum oxide solid electrolyte and preparation method thereof

A solid electrolyte and tantalum oxide technology, applied in the field of materials, can solve the problems of low proton transfer number, hydrogen measurement error, sensor display error, etc., achieve high proton transfer number, good conductivity, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

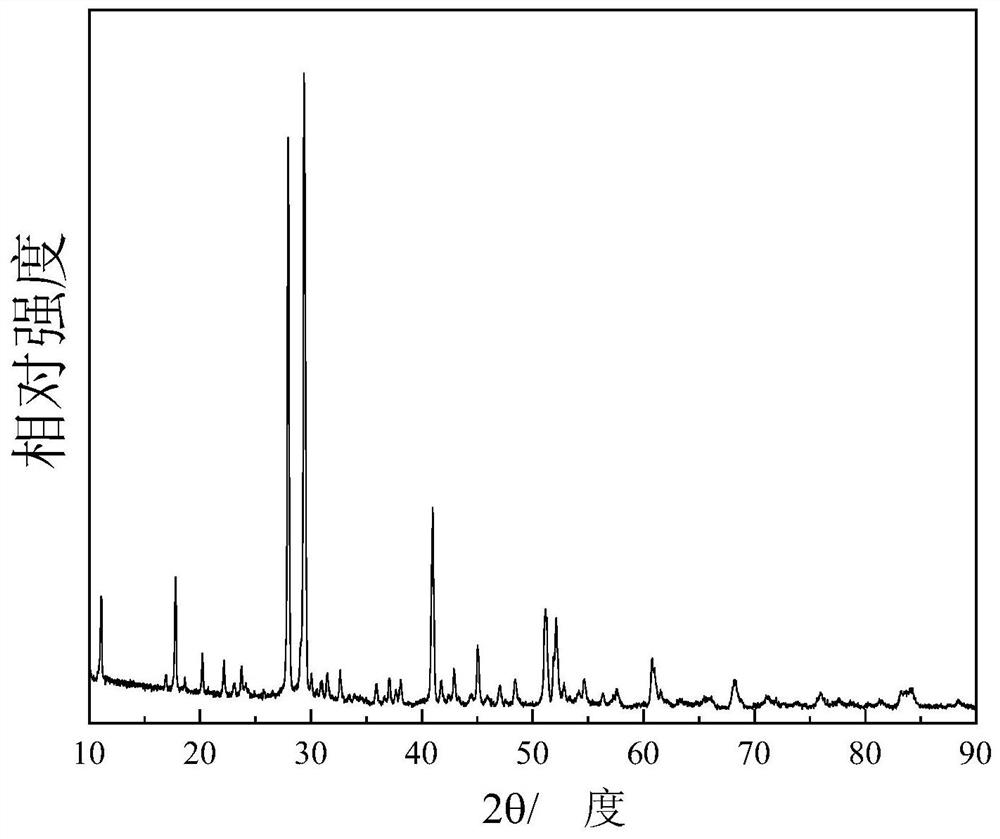

Embodiment 1

[0039] The molecular formula of barium barium tantalum oxide solid electrolyte is Ba 1.5 Ba 0.5+x Ta 1-x O 4.5-δ , where x=0, δ=0;

[0040] The preparation method is:

[0041] Prepare barium carbonate powder and tantalum oxide powder as raw materials; mix the raw materials in a molar ratio Ba:Ta=2:1 to make powder;

[0042] Using absolute ethanol as the ball-milling medium, the mixed powder was ball-milled to a particle size of less than 400 mesh, and then dried to remove the ball-milling medium to obtain ball-milling powder;

[0043]The ball mill powder is pressed into shape, then roasted at 1100°C for 5 hours, cooled to room temperature with the furnace, and the roasted material is obtained; the press shape is to place the ball mill powder in a mold, and use a press to shape it under a pressure of 30MPa;

[0044] Grind the calcined material to a particle size of 200 mesh or less, and then press it for the second time. The second press is to put the ground calcined mater...

Embodiment 2

[0047] The molecular formula of barium barium tantalum oxide solid electrolyte is Ba 1.5 Ba 0.5+x Ta 1-x o 4.5-δ , where x=0.05, δ=0.075;

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The molar ratio of powder Ba:Ta=2.05:0.95;

[0050] (2) Carry out ball milling with water as the ball milling medium;

[0051] (3) Roasting at 1300°C for 1 hour; press molding under a pressure of 50MPa using a press machine;

[0052] (4) Press into tablets under 50MPa pressure during secondary pressing, use a cold isostatic pressing device under 200±10MPa pressure for 15min, and then calcinate at 1500°C for 1h;

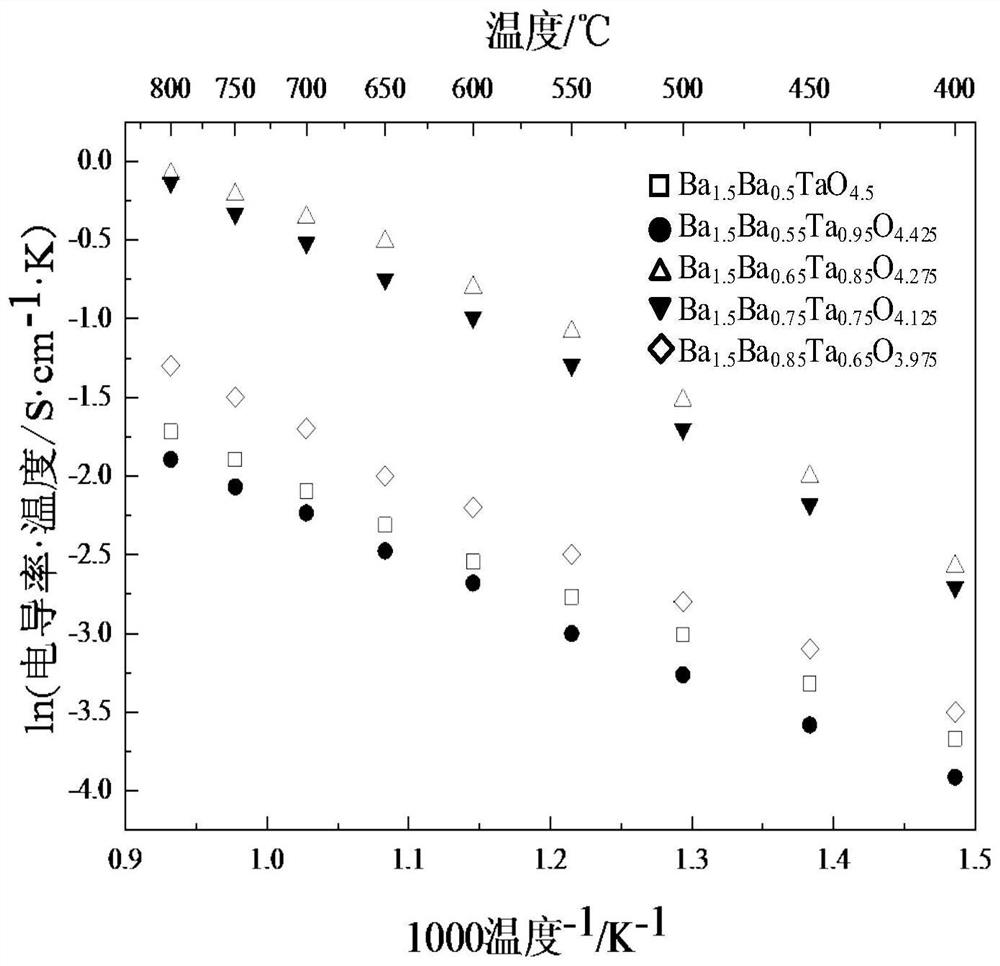

[0053] Barium, barium and tantalum oxide solid electrolytes have a conductivity of 3.0×10 at a temperature of 400-800°C, an oxygen volume concentration of 3%, a water vapor volume concentration of 1.8%, and the rest in an argon atmosphere. -5 ~1.4×10 -4 S cm -1 , the proton transfer number is 0.97-0.49; the conductivity at 700 °C is 1.1×10 -4 S cm -1 , ...

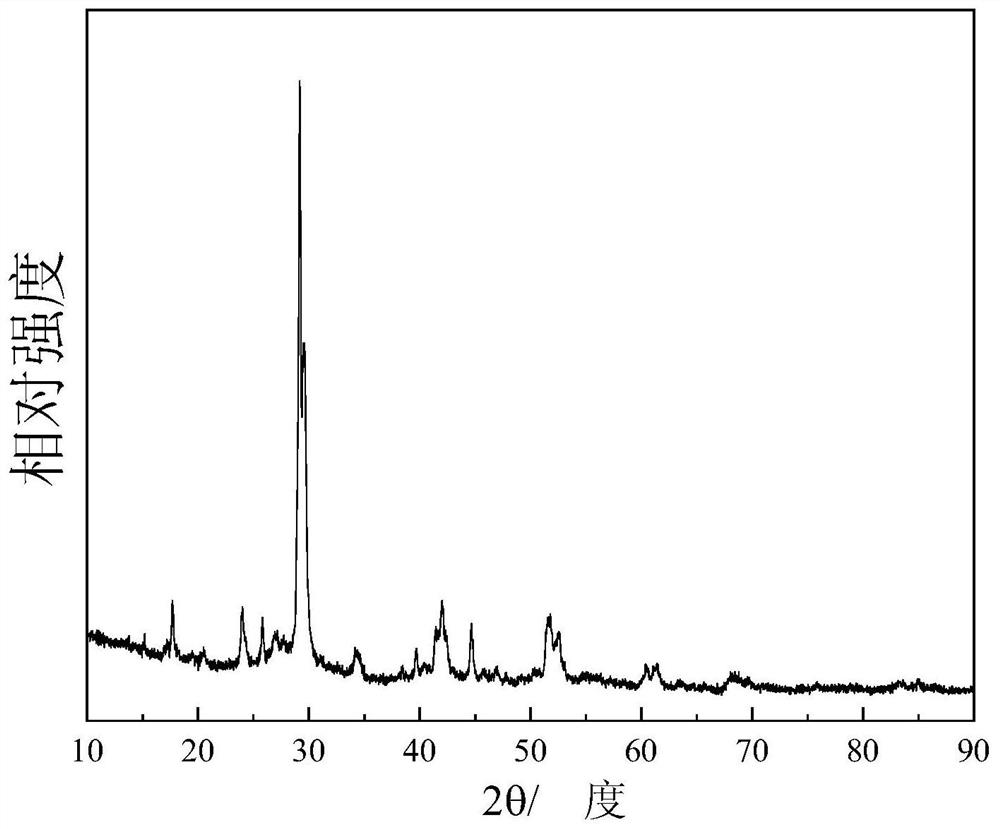

Embodiment 3

[0055] The molecular formula of barium barium tantalum oxide solid electrolyte is Ba 1.5 Ba 0.5+x Ta 1-x o 4.5-δ , where x=0.15, δ=0.225;

[0056] Method is with embodiment 1, and difference is:

[0057] (1) The molar ratio of powder Ba:Ta=2.15:0.85;

[0058] (2) Roasting at 900°C for 10 hours; press molding under a pressure of 10MPa using a press machine;

[0059] (3) During the secondary pressing, it was compressed into tablets under a pressure of 10MPa, and the cold isostatic pressing device was used to press at a constant pressure of 200±10MPa for 30min; after calcination at 1000°C for 10h; the XRD diagram is as follows figure 2 shown;

[0060] Barium, barium and tantalum oxide solid electrolytes have a conductivity of 1.1×10 at a temperature of 400-800°C, an oxygen volume concentration of 3%, a water vapor volume concentration of 1.8%, and the rest in an argon atmosphere. -4 ~8.6×10 -4 S cm -1 , the proton transfer number is 0.95-0.50; the conductivity at 700°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com