A kind of preparation method of mosapride intermediate

A technology for intermediates and compounds, applied in the field of preparation of mosapride intermediates, can solve the problems of prolonging the process route, increasing the time of mosapride citrate, capital consumption, high price and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

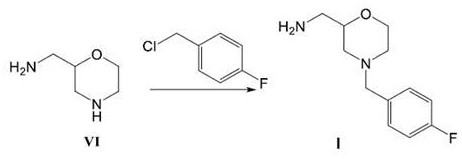

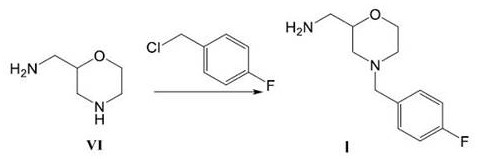

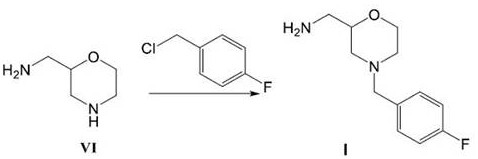

Image

Examples

Embodiment 1

[0061] Example 1 Preparation of 2-(2-hydroxyl-3-((2-hydroxyethyl)amino)propyl)isoindoline-1,3-dione

[0062]

[0063] Add phthalimide potassium salt (370.0g, 2mol) and 2L of absolute ethanol into the reaction flask, heat to 65°C and stir to dissolve. After the material is dissolved, add dichloroisopropanol (0.229L, 2.4mol), Triethylamine (0.557L, 4mol), reflux reaction for 6 hours to generate intermediate N-(2-hydroxyl-3-chloropropyl)phthalimide, lowered to room temperature, added 2-aminoethanol ( 0.241L, 4mol), heated up to 50°C and reacted for 6 hours, evaporated the ethanol to dryness under reduced pressure, added 10L each of ethyl acetate and water, separated the liquid, washed the water phase twice with ethyl acetate, washed the organic phase twice with water, and combined The organic phase was dried over anhydrous magnesium sulfate, filtered with suction, and evaporated to dryness under reduced pressure to obtain 472 g of a white solid, namely 2-(2-hydroxyl-3-((2-hydr...

Embodiment 2

[0064] Example 2 Preparation of 2-(2-hydroxyl-3-((2-hydroxyethyl)amino)propyl)isoindoline-1,3-dione

[0065]

[0066] Add phthalimide potassium salt (370.0g, 2mol) and 2L of absolute ethanol into the reaction flask, heat to 65°C and stir to dissolve. After the material is dissolved, add dichloroisopropanol (0.229L, 2.4mol), DMAP (0.539L, 4mol), reflux reaction 6 hours generates intermediate N-(2-hydroxyl-3-chloropropyl) phthalimide, is down to room temperature, adds 2-aminoethanol (0.241L , 4mol), heated up to 50°C and reacted for 6 hours, evaporated the ethanol to dryness under reduced pressure, added 10L each of ethyl acetate and water, separated the layers, washed the aqueous phase twice with ethyl acetate, washed the organic phase twice with water, and combined the organic phases , dried over anhydrous magnesium sulfate, suction filtered, and evaporated to dryness under reduced pressure to obtain a white solid that is 2-(2-hydroxyl-3-((2-hydroxyethyl)amino)propyl)isoind...

Embodiment 3

[0067] Example 3 Preparation of 2-(2-hydroxyl-3-((2-hydroxyethyl)amino)propyl)isoindoline-1,3-dione

[0068]

[0069] Add phthalimide potassium salt (370.0g, 2mol) and DMSO 2L into the reaction flask, heat to 65°C and stir to dissolve, add dichloroisopropanol (0.229L, 2.4mol), triethyl Amine (0.557L, 4mol), reflux reaction for 6 hours to generate intermediate N-(2-hydroxy-3-chloropropyl)phthalimide, lowered to room temperature, added 2-aminoethanol (0.241L , 4mol), heated up to 50°C and reacted for 6 hours, evaporated the ethanol to dryness under reduced pressure, added 10L each of ethyl acetate and water, separated the layers, washed the aqueous phase twice with ethyl acetate, washed the organic phase twice with water, and combined the organic phases , after drying over anhydrous magnesium sulfate, suction filtration, and evaporated to dryness under reduced pressure to obtain a white solid, namely 2-(2-hydroxyl-3-((2-hydroxyethyl)amino)propyl)isoindoline-1 , 3-diketone 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com