Preparation method and device of water-soluble polymer/inorganic nano-powder composite fiber, lithium ion battery negative electrode material and preparation method

A water-soluble polymer, inorganic nanotechnology, applied in active material electrodes, battery electrodes, conjugated synthetic polymer man-made filaments, etc., can solve the problems of high cost, poor environmental protection, spinning difficulties, etc., and achieve easy operation, Good stability, stable effect of spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

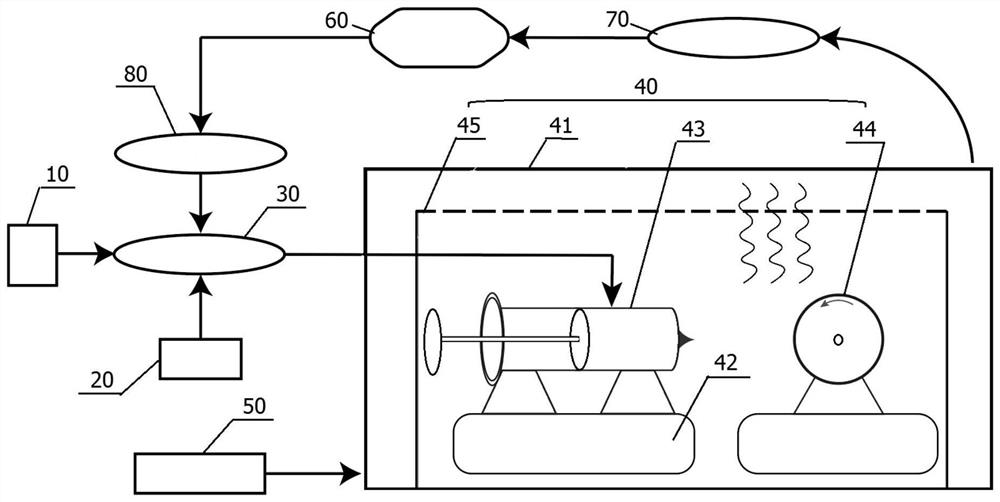

[0035] In order to solve the above problems, the present invention provides a method for preparing water-soluble polymer / inorganic nanopowder composite fiber, which includes the following steps: S1, using a mixed solvent of water and ethanol as a spinning solvent to configure a water-soluble polymer and the precursor slurry of inorganic nanopowder; wherein, the average molecular weight of the water-soluble polymer is 58,000-1,300,000; matter / nano-powder composite fiber.

[0036] The invention provides a method for preparing water-soluble polymer / inorganic nanopowder composite fiber, which uses a mixed solution of water and ethanol as a spinning solvent, and uses a relatively low-molecular-weight water-soluble polymer (average molecular weight 58,000-1,300,000 ) as a polymer substrate, adding nano-powder to prepare a precursor slurry, and then electrospinning under a specific humidity condition (30-60%), the spinning process is relatively stable, easy to operate, and can obtain...

Embodiment 1

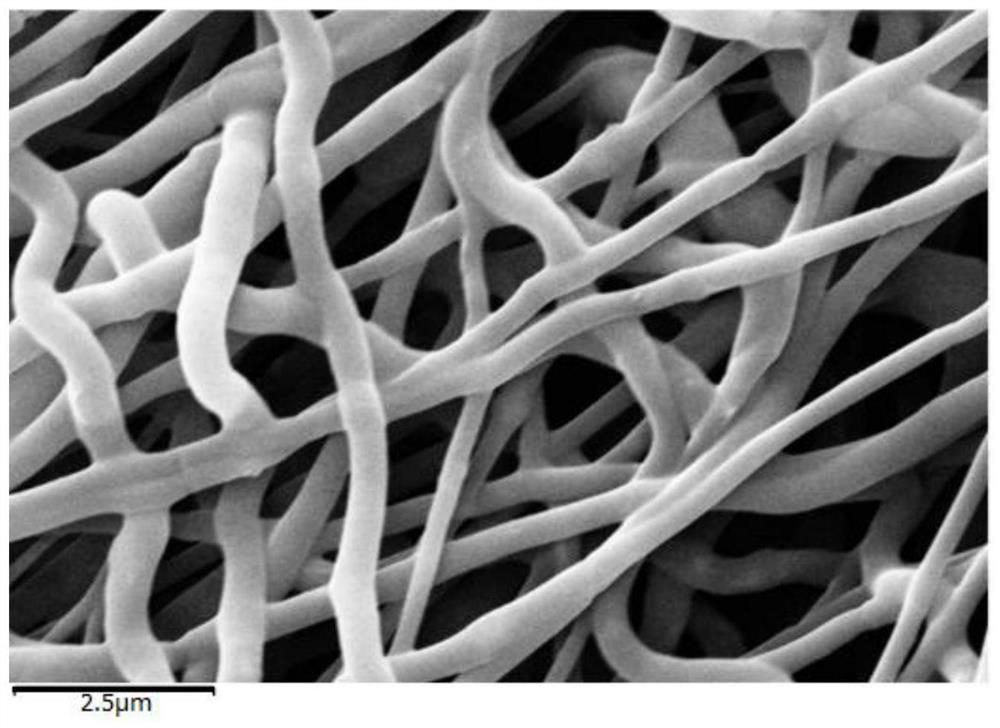

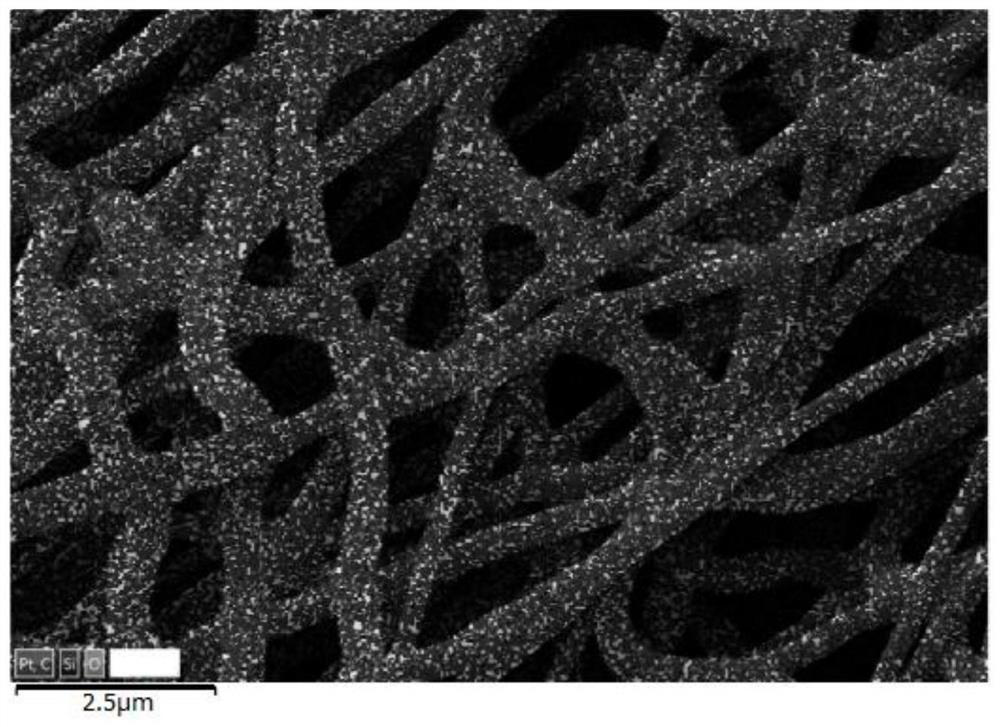

[0071] Prepare the precursor slurry with 500mL 30vol% ethanol-water, 30.13g nano-silica powder and 350g polyvinylpyrrolidone with a molecular weight of 58000 as raw materials, install the electrospinning module and set the receiving distance to 8cm, open the air inlet valve and exhaust Mouth, at 500mL min -1 The air with a humidity of 30% is passed through at a flow rate of 30% to purge the box. After the humidity in the box is stable, start the electrospinning, the positive voltage is 15kV, the negative voltage is 2kV, and the injection flow rate is 1500μL min -1 , the silicon-polyvinylpyrrolidone composite fiber was obtained on the collector, with a diameter of 500-900 nm, and the recovery rate was calculated to be about 53% based on the accumulated solvent recovery amount after running for 4 hours. Silicon-polyvinylpyrrolidone composite fibers are subjected to two-stage low-temperature heat treatment at 150°C and 250°C and high-temperature heat treatment at 400°C to obtain...

Embodiment 2

[0073] Prepare precursor slurry with 500mL 50vol% ethanol-water, 58.11g nano silicon powder and 300g polyvinylpyrrolidone with a molecular weight of 58000 as raw materials, install the electrospinning module and set the receiving distance to 10cm, open the air inlet valve and exhaust Mouth, at 500mL min -1 Air with a humidity of 40% is passed through at a flow rate to purge the box. After the humidity in the box is stable, start the electrospinning, the positive voltage is 20kV, the negative voltage is 2kV, and the injection flow rate is 2000μL min -1 , silicon-polyvinylpyrrolidone composite fibers were obtained on the collector, with a diameter of 200-400nm, and the recovery rate was calculated to be about 47% based on the cumulative solvent recovery after running for 4 hours. Silicon-polyvinylpyrrolidone composite fibers are subjected to two-stage low-temperature heat treatment at 180°C and 250°C and high-temperature heat treatment at 500°C to obtain silicon-carbon composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com