Tin telluride-based electrode material and preparation method thereof, and lithium ion battery

An electrode material, tin telluride-based technology, applied in the field of lithium ion batteries, can solve the problems of agglomeration, expansion and pulverization, insufficient conductivity of telluride electrode materials, etc., and achieve improved interface, low cost, and good electrochemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

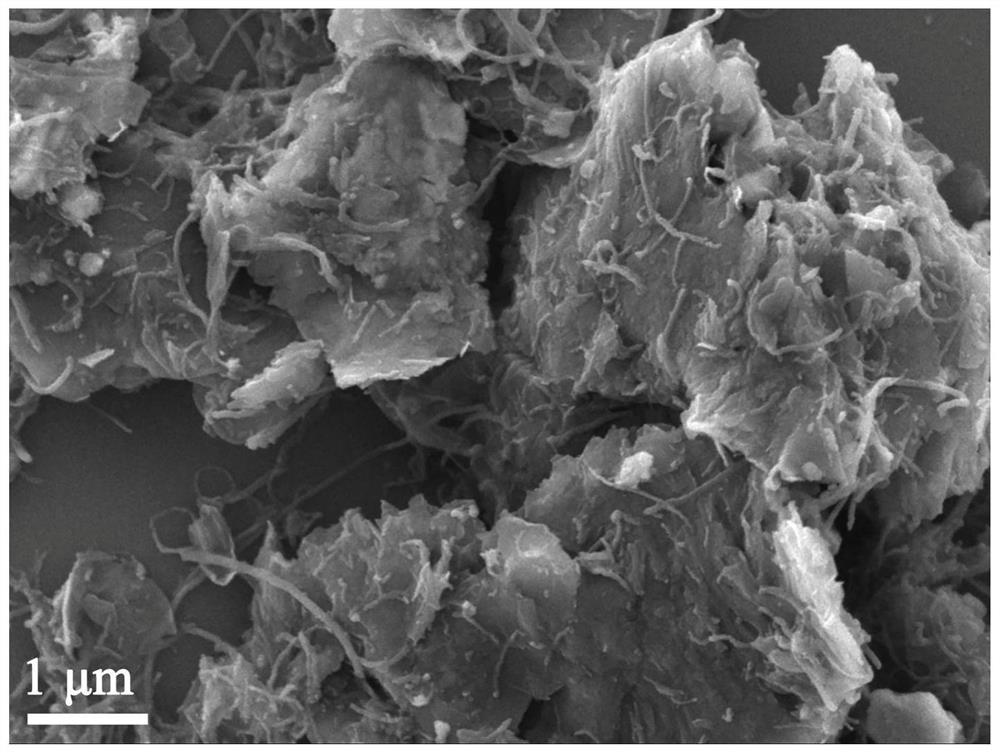

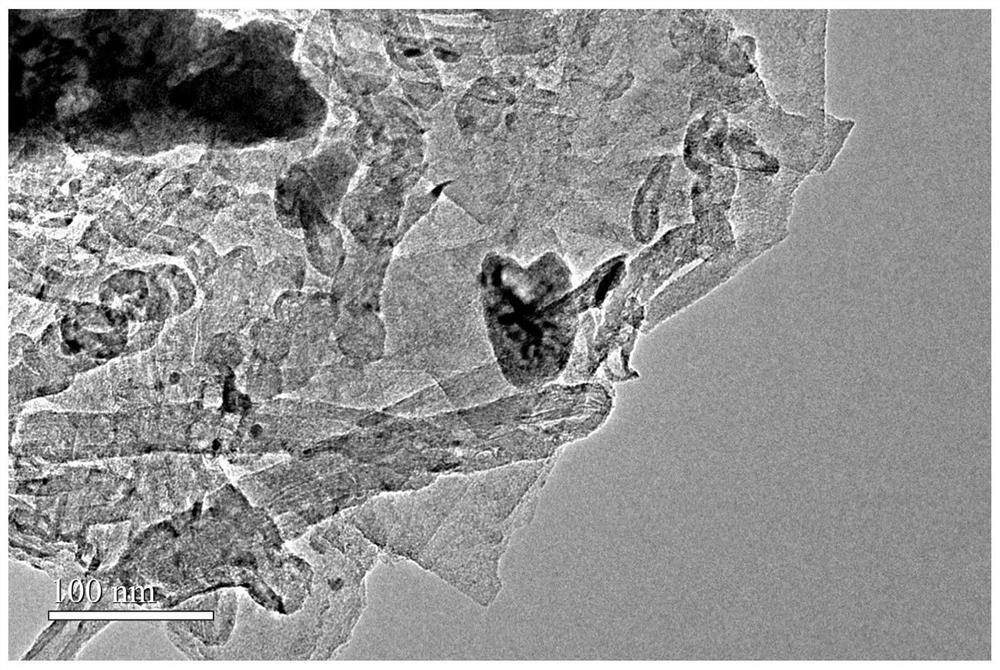

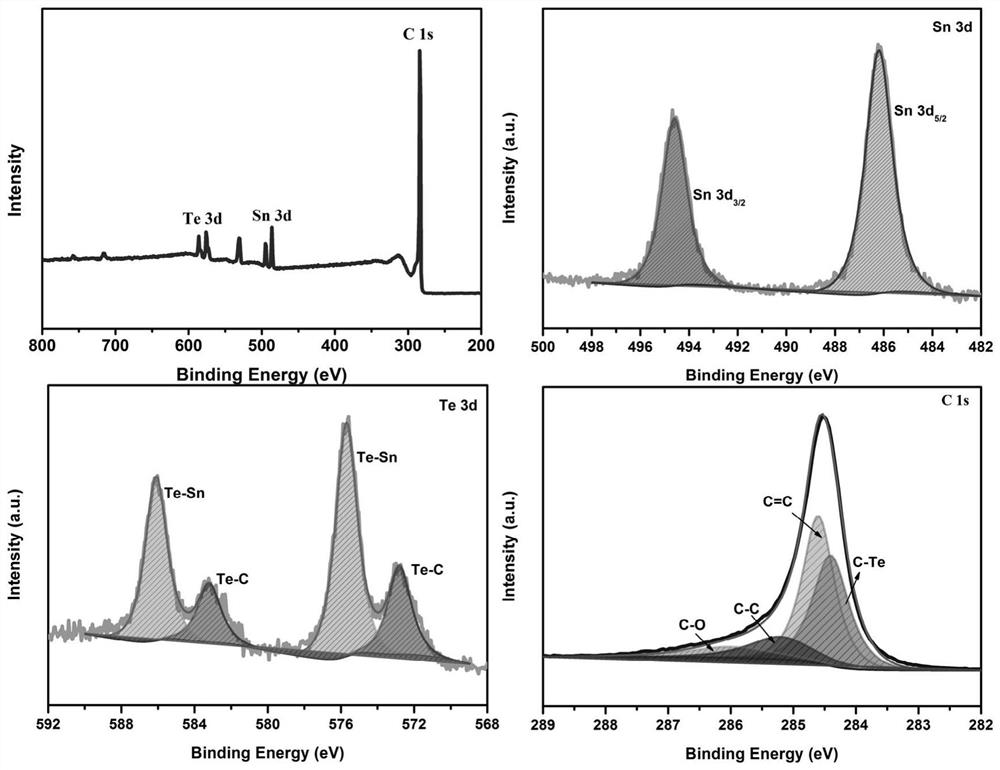

[0046] Take a certain quality of raw materials, and take a certain amount of ball milling beads. The mass of block SnTe is 1.0g, the quality of graphite is 0.8g, and the quality of multi-walled carbon nanotubes is 0.2g. The mass ratio is 1:30, under the protection of argon atmosphere, the ball milling speed is 500rpm, and the ball milling time is 15h, and then the SnTe-CNT-G electrode material is obtained. The structure of the electrode material prepared in this embodiment is shown in Figure 1 ~ Figure 2The composition and properties of electrode materials are shown in Figure 3 ~ Figure 4 As shown, the performance comparison chart of electrode materials is shown in Figure 5a , Figure 5b and Figure 5c shown.

Embodiment 2

[0048] Weigh a certain quality of raw materials, and weigh a certain amount of ball milling beads. The mass of bulk SnTe is 1.0g, the mass of graphite is 1.0g, and the mass of multi-walled carbon nanotubes is 0g. The ratio is 1:20, under the protection of nitrogen atmosphere, the ball milling speed is 600rpm, the ball milling time is 10h, and then the SnTe-CNT-G electrode material is obtained.

Embodiment 3

[0050] Take a certain quality of raw materials, and take a certain amount of ball milling beads. The mass of block SnTe is 1.2g, the quality of graphite is 0.6g, and the quality of multi-walled carbon nanotubes is 0.2g. The mass ratio is 1:40, under the protection of nitrogen atmosphere, the ball milling speed is 450rpm, and the ball milling time is 15h, and then the SnTe-CNT-G electrode material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com