Preparation method and application of modified carbon cloth

A technology for modifying carbon and carbon cloth, which is used in fuel cells, regenerative fuel cells, electrical components, etc., to achieve the effects of easy operation, simple equipment, and improved conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

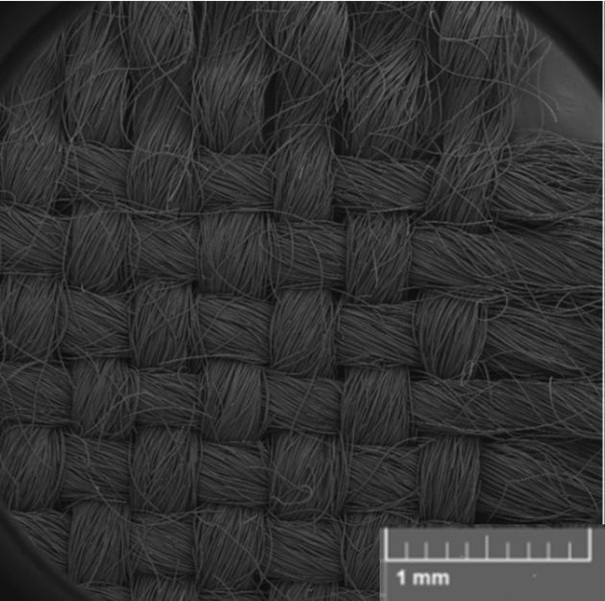

[0042] This embodiment provides a preparation method of modified carbon cloth, including:

[0043] Commercially available carbon cloth was first pretreated: soaked in concentrated sulfuric acid solution for 10 hours, then washed and dried.

[0044] 1) Zinc salt and surfactant are made into zinc salt solution, and the carbon cloth is immersed in the zinc salt solution.

[0045] The proportioning of the zinc salt solution is: by 30g Zn(CH 3 COO) 2 2H 2 O and 10g of polyethylene glycol (PEG400) were added to 100g of water to prepare a solution, ultrasonicated for 15 minutes to obtain a zinc salt solution, and the carbon cloth was immersed in the zinc salt solution for 2 hours and then taken out.

[0046] 2) The carbon cloth obtained in step 1) was dried and calcined; the calcining temperature was 280° C. for 1.5 hours.

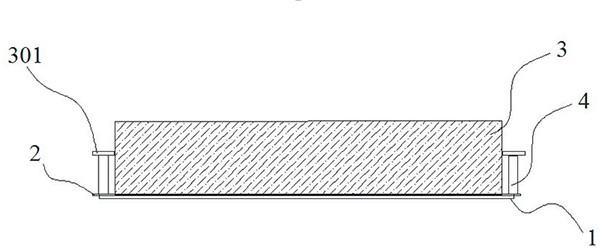

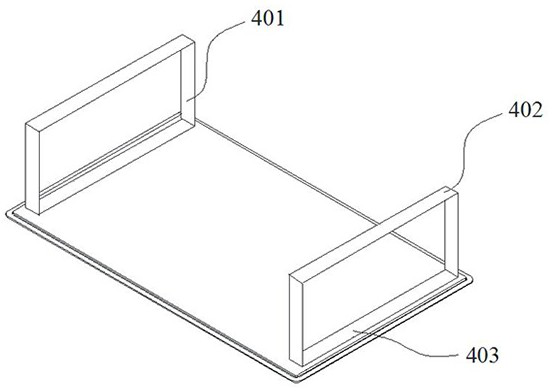

[0047] A single battery was assembled with the modified carbon cloth of this embodiment, and the structure of the battery was the same as that of the test ex...

Embodiment 2

[0050] This embodiment provides a preparation method of modified carbon cloth. The pretreatment and step 1) are basically the same as in Example 1, except that 40g Zn(CH 3 COO) 2 2H 2 The ratio of O to 10g polyethylene glycol (PEG400) added to 100g water is used to prepare zinc salt solution.

[0051] A single battery was assembled with the modified carbon cloth of this embodiment, and the structure of the battery was the same as that of the test example; the internal resistance of the battery was 1.3 milliohms.

Embodiment 3

[0053] This embodiment provides a preparation method of modified carbon cloth. The pretreatment and step 1) are basically the same as in Example 1, except that 20g Zn(CH 3 COO) 2 2H 2 The ratio of O to 10g of polyethylene glycol (PEG400) added to 100g of water to make a zinc salt solution.

[0054] A single battery was assembled with the modified carbon cloth of this embodiment, and the structure of the battery was the same as that of the test example; the internal resistance of the battery was 1.4 milliohms.

[0055] The result of comparative example 1-3, the proportioning of preferred zinc salt solution is by 30g Zn(CH 3 COO) 2 2H 2The ratio of O to 10g polyethylene glycol (PEG400) added to 100g water was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com