Chemical remover for treating heavy metal polluted wastewater as well as preparation method and application of chemical remover

A chemical removal and wastewater treatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of residual precipitant, secondary pollution, large usage, etc., to achieve Low cost, wide range of raw material sources, enhanced removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

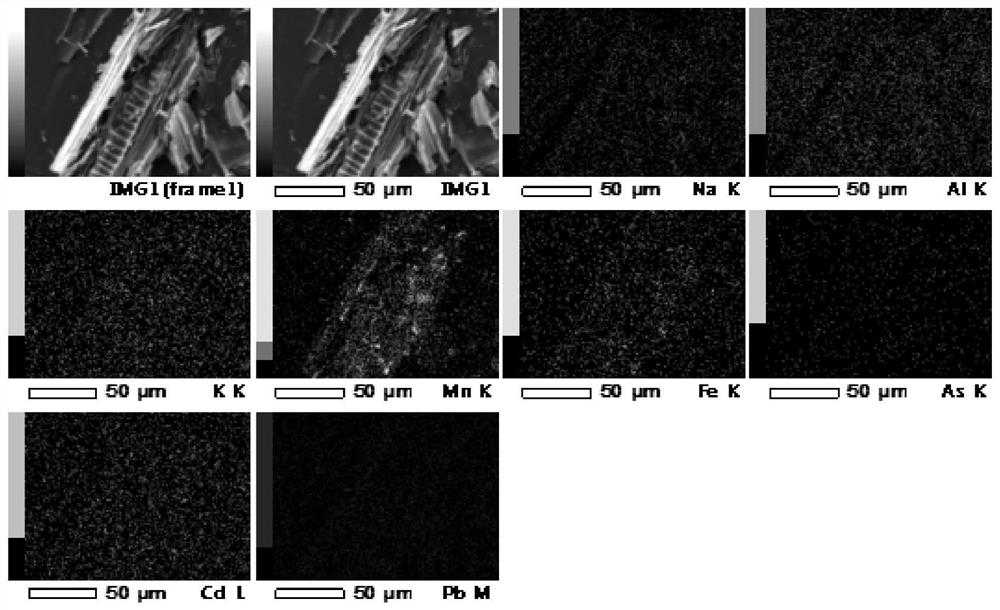

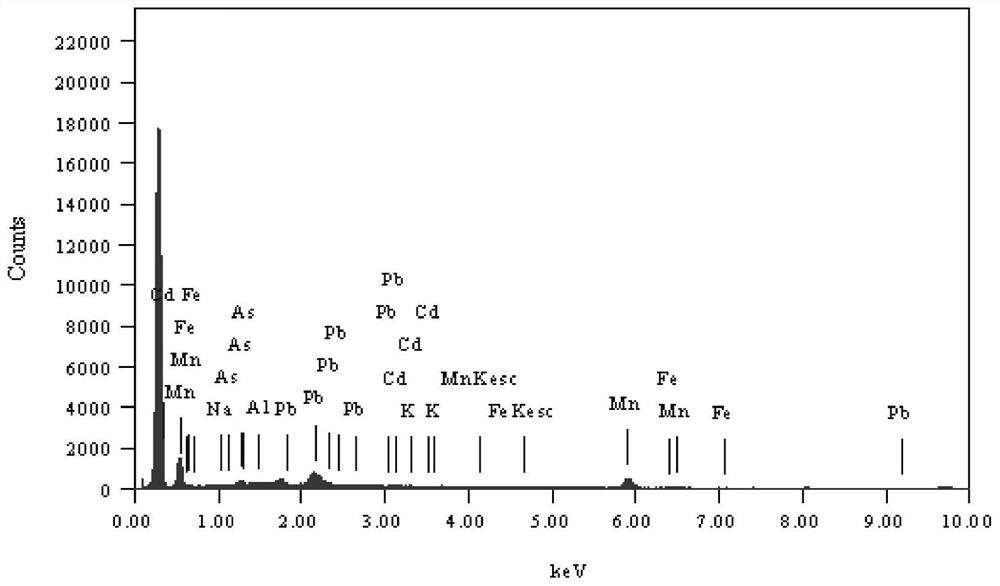

Embodiment 1

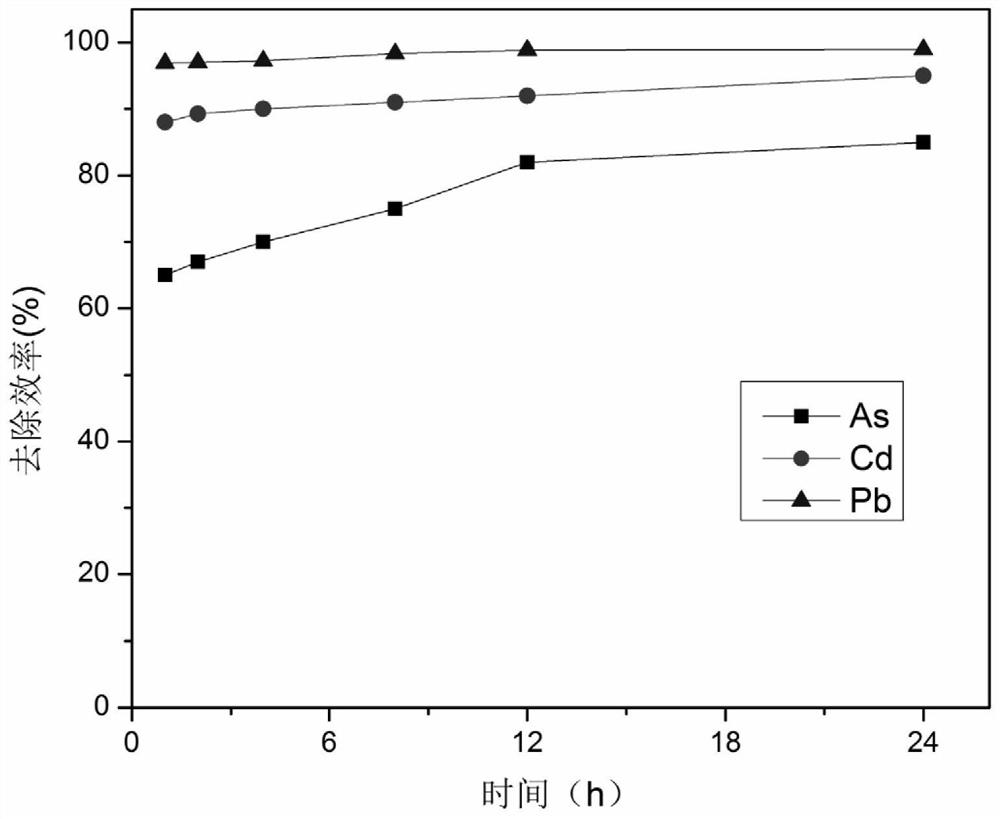

[0044] Wash 10g of rice stalks in an ultrasonic cleaner for 10 minutes, dry and crush them, and pass through a 40-mesh sieve for later use; configure 0.1mol·L -1 of citric acid and Mn(NO 3 ) 2 solution, 18ml of Mn(NO 3 ) 2 Slowly add the solution into 10g of rice straw, slowly add 18ml of citric acid solution and 40ml of ultrapure water along the inner wall of the container and stir and mix continuously; under the action of a magnetic stirrer, stir the mixed solution at a rate of 300rpm for 120min, take out and stir After baking in a drying oven at 105°C in a constant temperature oven to constant weight; place the dried material in a sealed container, heat it to 550°C in a muffle furnace at a rate of 5°C / min and continue roasting for 180min, after the roasting is completed , cooled and ground through a 40-mesh sieve to prepare a waste water heavy metal remover.

[0045] Measure 100ml of lead, cadmium and arsenic contaminated wastewater, add 0.5g of the above remover, and mix...

Embodiment 2

[0047] Wash 10 g of rice straw in an ultrasonic cleaner for 10 minutes, dry and crush, pass through a 40-mesh sieve for later use; configure 0.05mol L -1 Oxalic acid and Fe(NO 3 ) 2 solution, 18ml of Fe(NO 3 ) 2 Slowly add the solution to 10g of rice straw, slowly add 18ml of oxalic acid solution and 40ml of ultrapure water along the inner wall of the container and stir and mix continuously; under the action of a magnetic stirrer, stir the mixed solution at a speed of 300rpm for 120min, take out the stirrer Finally, bake in a drying oven to a constant weight at 105°C in a constant temperature oven; place the dried material in a sealed container, heat it to 550°C in a muffle furnace at a rate of 5°C / min and continue roasting for 180min. After the roasting is completed, Cool and grind through a 40-mesh sieve to prepare a waste water heavy metal remover.

[0048] Measure 100ml of lead, cadmium and arsenic contaminated wastewater, add 0.4g of the above remover, and mix well. ...

Embodiment 3

[0050] Wash 10g of rice stalks in an ultrasonic cleaner for 10 minutes, dry and crush them, and pass through a 40-mesh sieve for later use; configure 0.1mol·L -1 of citric acid, Mn(NO 3 ) 2 solution and Fe(NO 3 ) 2 solution, 9ml of Mn(NO 3 ) 2 solution with 9ml of Fe(NO 3 ) 2 Slowly add the solution into 10g of rice straw, slowly add 18ml of citric acid solution and 40ml of ultrapure water along the inner wall of the container, and keep stirring and mixing; under the action of a magnetic stirrer, keep stirring the mixed solution at a rate of 300rpm for 120min, take out and stir After baking in a drying oven at 105°C in a constant temperature oven to constant weight; place the dry material in a sealed container, heat it to 550°C in a muffle furnace at a heating rate of 5°C / min and continue roasting for 180min. After the roasting is completed , cooled and ground through a 40-mesh sieve to prepare a waste water heavy metal remover.

[0051] Measure 100ml of lead, cadmium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com