Manufacturing method of personalized absorbable support bone grafting plate for developmental dysplasia of hip

A technology of dysplasia and manufacturing method, which is applied in the direction of acetabular socket, hip joint, additive manufacturing, etc., can solve the problem that it is difficult to clearly determine the degree of acetabular and femoral head lesions, the size of the acetabulum, and the difficulty in meeting the needs of the acetabulum in patients with DDH. Coverage, lack of production methods and other issues, to achieve the effect of correcting abnormal acetabular angle, reducing surgical trauma, and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A first aspect of the present invention provides:

[0041] A manufacturing method for a personalized acetabular dysplasia supporting bone graft plate, comprising:

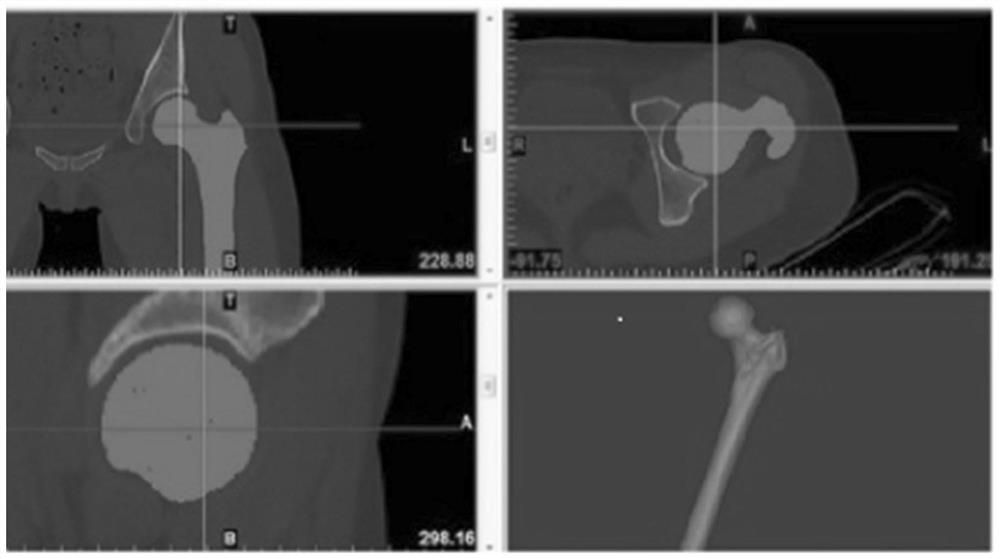

[0042] 1) Obtain CT scan data of the patient's hip joint;

[0043] 2) Based on the CT scan data, the contour lines of each layer of the cortical bone wheel and the contour line of the cancellous bone are generated, and the curvature of the contour line must match the normal shape of the acetabulum;

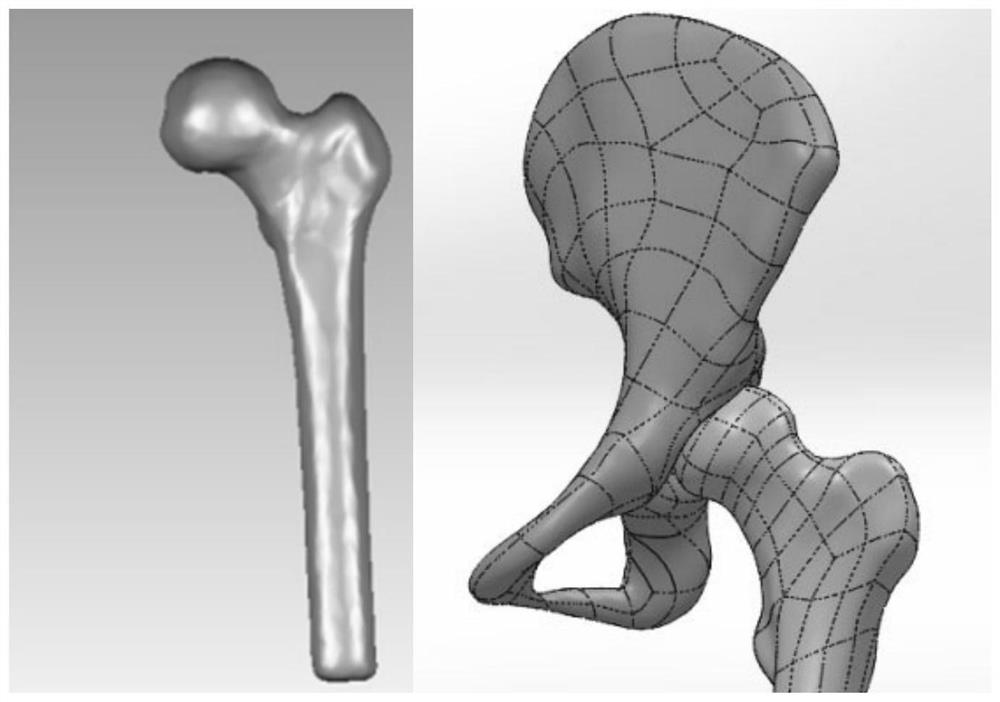

[0044] 3) Generate cortical bone and cancellous bone 3D models based on the cortical bone contour line and cancellous bone contour line respectively;

[0045] 4) The 3D models of cortical bone and cancellous bone were assembled after origin registration, and the 3D models of cortical bone and cancellous bone were obtained by calculation, and the hip joint bone model was established through assembly;

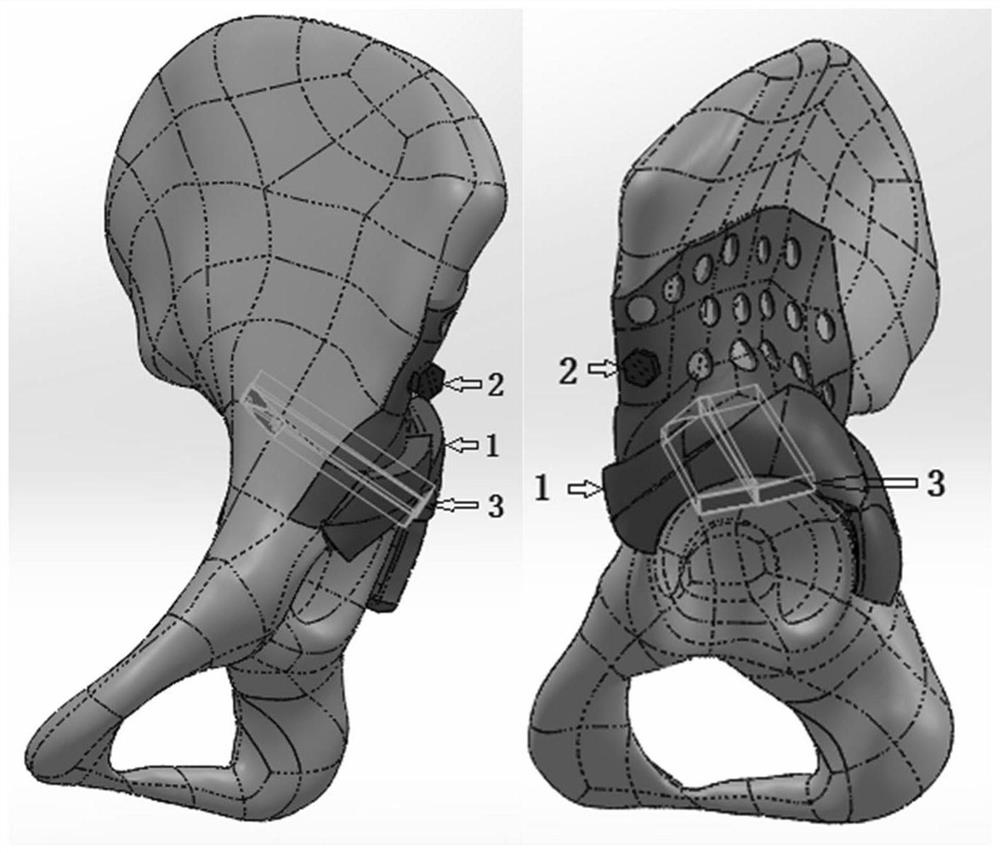

[0046] 5) According to the damage condition of the three-dimensional model of cortical bone and cancellous bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com