Equipment and method for cyclic reaction and continuous separation of magnetic particles in heterogeneous reaction

A technology of magnetic particles and cyclic reactions, applied in chemical instruments and methods, chemical/physical/physicochemical processes using energy, oxidized water/sewage treatment, etc., can solve problems such as increasing costs, not being able to recycle, hindering applications, etc., to achieve Easy operation, high reaction efficiency, exquisite design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

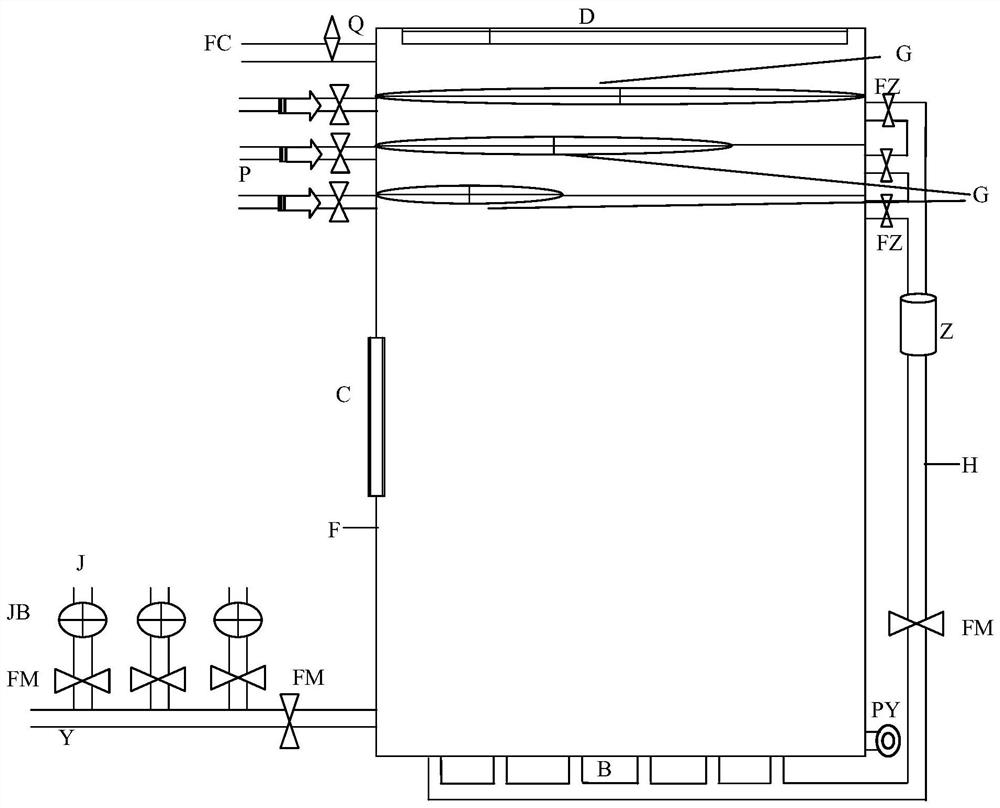

[0034] Such as figure 1As shown, the equipment for circular reaction and continuous separation of magnetic particles in the heterogeneous reaction of this embodiment includes: reactor F, reactant inflow pipeline Y, dosing pipeline J, reactant outflow pipeline FC, outlet PY, Filtration magnetic mesh screen G, jet pump P, branch circuit inlet FZ, loop pipeline H, self-priming pump Z and water distributor pipeline B; wherein, the inside of the reactor F has a closed space; the side outside the reactor F The bottom of the wall is provided with a reactant inflow pipeline Y, which is connected to the inside of the reactor F; three connected dosing pipelines J are arranged on the reactant inflow pipeline Y, and a dosing pump is set on each dosing pipeline J JB; a reactant outflow pipeline FC is provided on the top of the sidewall outside the reactor F, and is connected to the inside of the reactor F; a discharge port PY is provided at the bottom of the sidewall of the reactor F oppos...

Embodiment 2

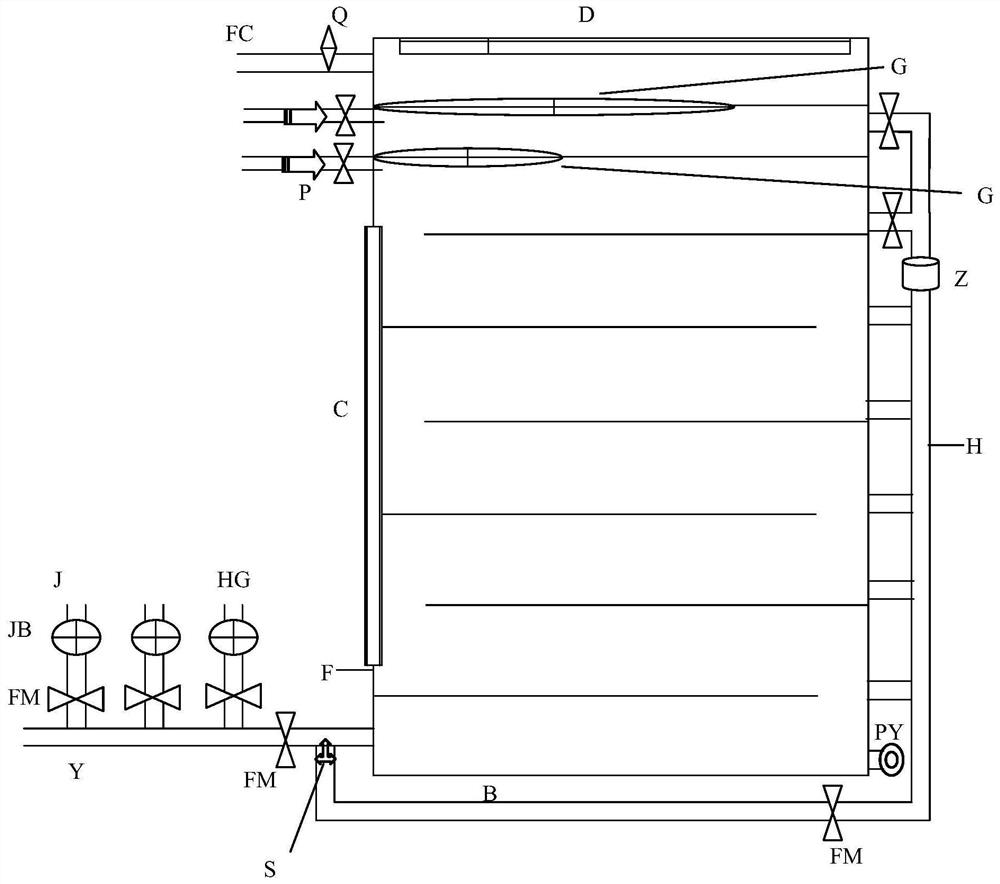

[0045] Such as figure 2 As shown, in this embodiment, the flow rate of the liquid inlet is fast, and the fluid is turbulent; in the reactor F, the partitions are placed horizontally at equal intervals from bottom to top, and the area of the partitions is smaller than the horizontal area of the internal space of the reactor F. The plates are arranged in a staggered manner, that is, the partitions are alternately connected with the side walls of one side, thereby forming a serpentine channel in the reactor F; the liquid inlet speed is very fast, and the length of the liquid flow channel is increased through the serpentine channel, thereby To ensure a long reaction time; corresponding to each layer of partitions, a branch circuit outlet is provided, each branch circuit outlet is connected to the circuit pipeline under the self-priming pump, and the branch circuit outlet will suspend the reaction of magnetic particles The final fluid is transported back to the reactor to keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com