Crack-resistant concrete for large-span buildings and preparation method thereof

A constructional, large-span technology, applied in the field of building materials, can solve the problems of poor durability and short service life, and achieve the effect of preventing fracture, improving service life and improving crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

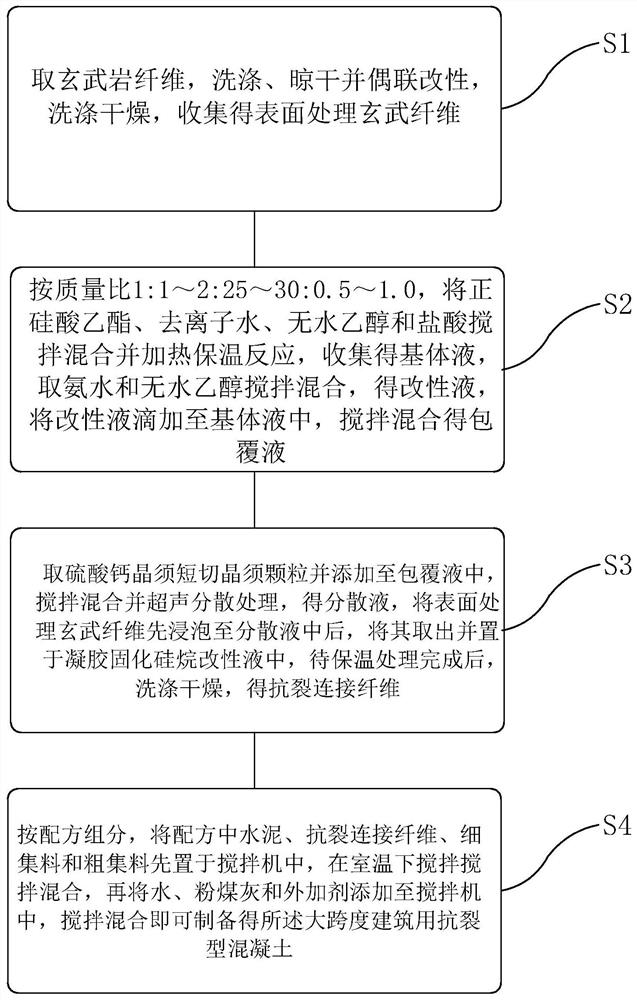

Method used

Image

Examples

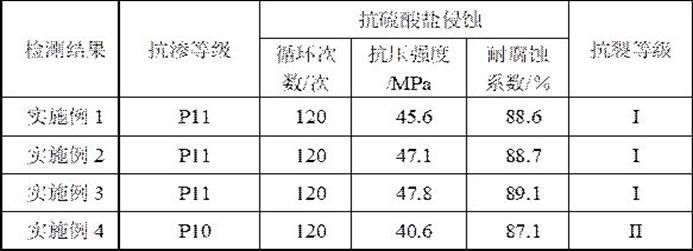

Embodiment 1

[0033] Take the basalt fiber and wash it with absolute ethanol for 3 times, dry it naturally and soak the basalt fiber in the silane coupling agent KH-560 according to the mass ratio of 1:10, let it stand naturally for 6 hours, and rinse it with deionized water for 3 times , dry naturally, and collect surface-treated basalt fibers;

[0034] According to the mass ratio of 1:1:25:0.5, stir and mix ethyl orthosilicate, deionized water, absolute ethanol and 0.1mol / L hydrochloric acid and place it at 55°C for 25 minutes, collect the base liquid, and then According to the mass ratio of 1:15, stir and mix the mass fraction of 5% ammonia water and absolute ethanol to obtain the modified liquid, and according to the mass ratio of 1:10, add the modified liquid dropwise to the base liquid, stir and mix, and stir at room temperature 25min, to obtain the coating solution;

[0035]Take calcium sulfate whiskers and cut them into short-cut whisker particles with a particle size of 1mm. Add t...

Embodiment 2

[0038] Take the basalt fiber and rinse it with absolute ethanol for 4 times, dry it naturally and soak the basalt fiber into the silane coupling agent KH-560 according to the mass ratio of 1:10, let it stand naturally for 7 hours, and rinse it with deionized water for 4 times , dry naturally, and collect surface-treated basalt fibers;

[0039] According to the mass ratio of 1:1:27:0.7, stir and mix ethyl orthosilicate, deionized water, absolute ethanol and 0.1mol / L hydrochloric acid and place it at 57°C for 27 minutes, collect the base liquid, and then According to the mass ratio of 1:15, stir and mix the mass fraction of 5% ammonia water and absolute ethanol to obtain the modified liquid, and according to the mass ratio of 1:10, add the modified liquid dropwise to the base liquid, stir and mix, and stir at room temperature 27min, the coating solution was obtained;

[0040] Take calcium sulfate whiskers and cut them into short-cut whisker particles with a particle size of 1 m...

Embodiment 3

[0043] Take the basalt fiber and wash it with absolute ethanol for 5 times, dry it naturally and soak the basalt fiber in the silane coupling agent KH-560 according to the mass ratio of 1:10, let it stand for 8 hours naturally, and rinse it with deionized water for 5 times , dry naturally, and collect surface-treated basalt fibers;

[0044] According to the mass ratio of 1:2:30:1.0, stir and mix ethyl orthosilicate, deionized water, absolute ethanol, and 0.1mol / L hydrochloric acid and place it at 60°C for 30 minutes, collect the base liquid, and then According to the mass ratio of 1:15, stir and mix the mass fraction of 5% ammonia water and absolute ethanol to obtain the modified liquid, and according to the mass ratio of 1:10, add the modified liquid dropwise to the base liquid, stir and mix, and stir at room temperature 30min, the coating solution was obtained;

[0045] Take calcium sulfate whiskers and cut them into short-cut whisker particles with a particle size of 2mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com