A kind of surfactant type corrosion inhibitor and preparation method thereof

A surfactant and corrosion inhibitor technology, applied in the field of organic polymer corrosion inhibitors, can solve the problems of less research, many adsorption active centers, low toxicity, etc., and achieve the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

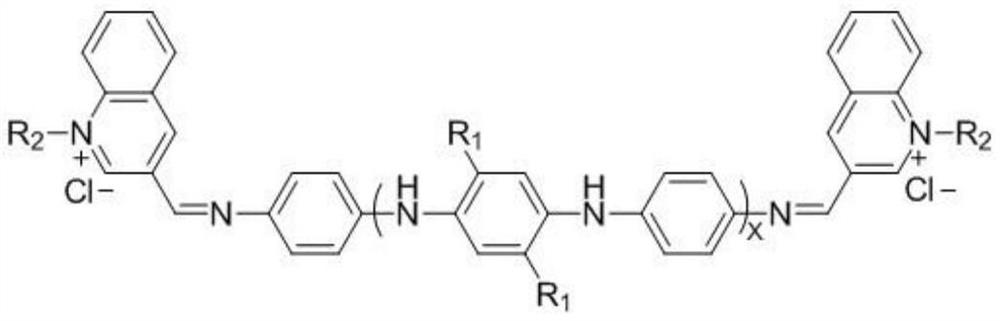

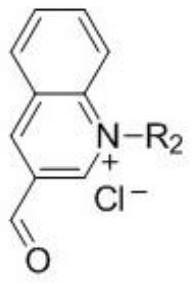

Method used

Image

Examples

Embodiment 1

[0031] Prepare amino-terminated polyaniline derivatives, denoted as A1.

[0032] Accurately weigh 15.01g (0.14mol) of p-phenylenediamine, 0.06g (0.10mmol) of bis(dibenzylideneacetone) palladium, 5.02g (0.05mol) of sodium tert-butoxide into the reaction kettle, and add 30mL of toluene to dissolve After 15 minutes, 5 mL of tri-tert-butylphosphine was injected, and the temperature was raised to 100 °C, and the toluene solution of 2,5-dihexyl-1,4-dibromobenzene [46.75 g (0.12 mol) dissolved in 60mL of toluene], drop it in 0.5h, keep the temperature for 10h, after the reaction, the solvent was distilled off under reduced pressure to obtain a yellow-brown powder, washed with deionized water 3 times, and dried in a vacuum oven at 50°C for 24h to obtain amino-terminated polyaniline derivative.

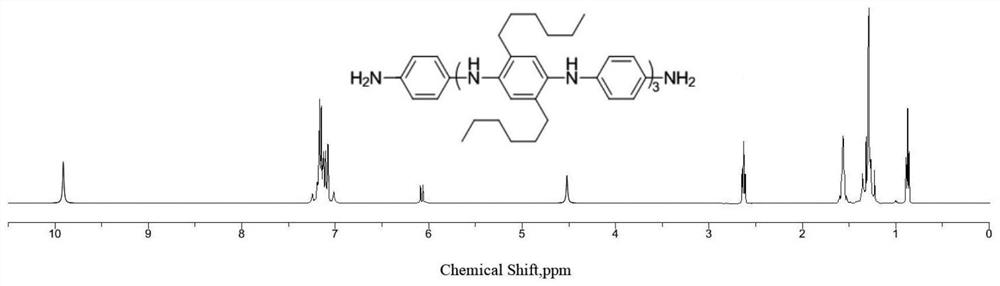

[0033] Amino-terminated polyaniline derivatives 1 H-NMR with CDCl 3 As a solvent, the result calculated to obtain the degree of polymerization x is 3, the results refer to the attached fig...

Embodiment 2

[0035] Prepare amino-terminated polyaniline derivatives, denoted as A2.

[0036] Accurately weigh 25.07g (0.23mol) of p-phenylenediamine, 0.06g (0.27mmol) of palladium acetate, 6.06g (0.06mol) of sodium tert-butoxide and add them to the reaction kettle, add 50mL of dioxane to dissolve, and pass in argon After 15 minutes, 0.39g (1.49mmol) tri-tert-butylphosphine was added, and the temperature was raised to 100°C, and the toluene solution of 2,5-dihexyl-1,4-dibromobenzene was added dropwise [78.09g (0.19mol) dissolved in 100mL toluene], drop it in 0.5h, heat preservation reaction 10h, after the reaction is over, the solvent is distilled off under reduced pressure to obtain a yellow-brown sticky substance, after adding dichloromethane to dissolve, after extracting with deionized water for 3 times, distill under reduced pressure, Amino-terminated polyaniline derivatives are obtained.

[0037] Amino-terminated polyaniline derivatives 1 H-NMR with CDCl 3 As a solvent, the result ...

Embodiment 3

[0039] Prepare amino-terminated polyaniline derivatives, denoted as A3.

[0040]Accurately weigh 20.02g (0.19mol) of p-phenylenediamine, 0.06g (0.27mmol) of palladium acetate, 6.18g (0.06mol) of sodium tert-butoxide and add them to the reaction kettle, add 40mL of toluene to dissolve, and blow in argon for 15min Then add 0.4g (1.52mmol) tri-tert-butylphosphine, raise the temperature to 120°C and start to drop the toluene solution of 2,5-dioctyl-1,4-diiodobenzene [73.3g (0.13mol) dissolved in 100mL toluene ], drop it within 1 hour, heat preservation reaction for 12 hours, and remove the solvent under reduced pressure at 100°C after the reaction to obtain a black viscous substance, add dichloromethane to dissolve, extract 3 times with deionized water, and then distill under reduced pressure at 80°C , to obtain amino-terminated polyaniline derivatives.

[0041] Amino-terminated polyaniline derivatives 1 H-NMR with CDCl 3 As a solvent, the result calculated that the degree of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com