Multipurpose wet rubbing fastness improving agent and preparation method thereof

A technology of wet rubbing fastness and improving agent, which is applied in the field of multi-purpose wet rubbing fastness improving agent and its preparation, can solve problems such as poor persistence of working fluid, unstable working fluid, poor wet rubbing fastness, etc., and achieve No hard feeling, good continuous processability, no drop in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The multi-purpose wet rubbing fastness improving agent obtained in Example 1 includes: 35 parts of isocyanate-terminated prepolymers, 20 parts of the above-mentioned (formula 2) structural components, 0.6 parts of dibutyltin dilaurate, 5 parts of glycerin, and formic acid 5 parts, 6 parts of octadecyltrimethyl ammonium chloride, 28 parts of the above-mentioned (formula 7) structural components, 0.8 parts of azodiisobutylamidine hydrochloride, and 40 parts of deionized water.

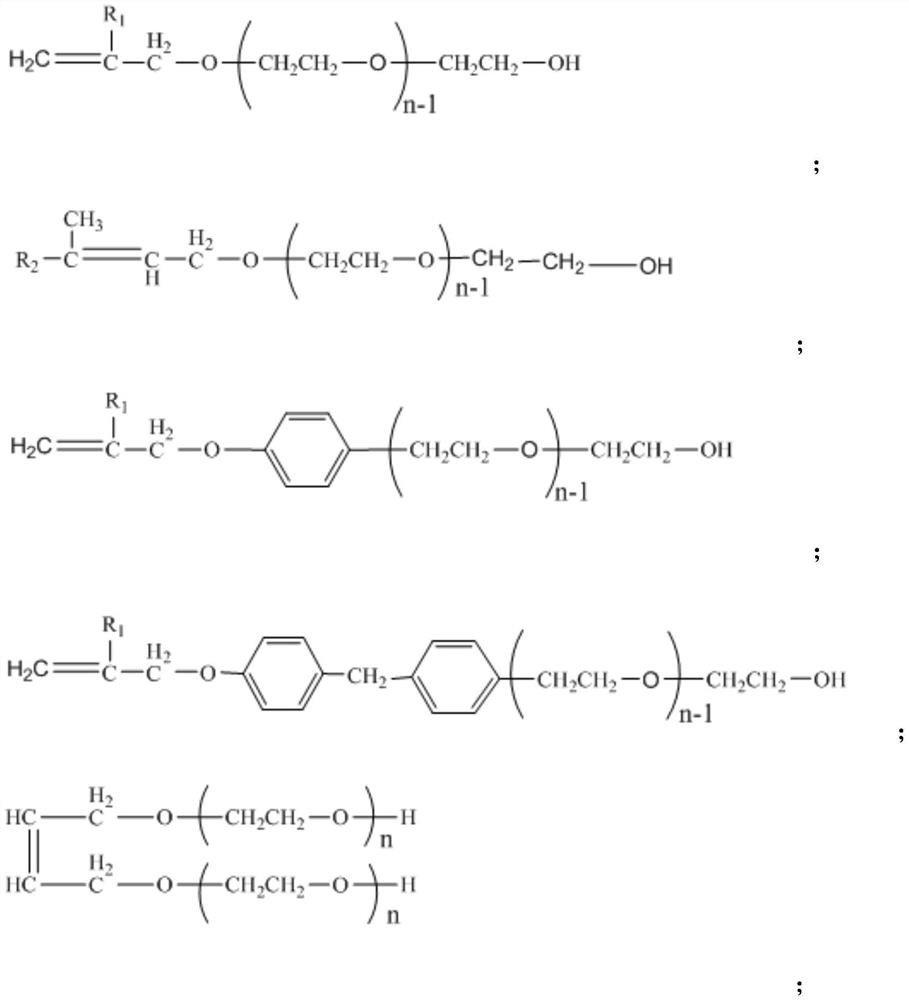

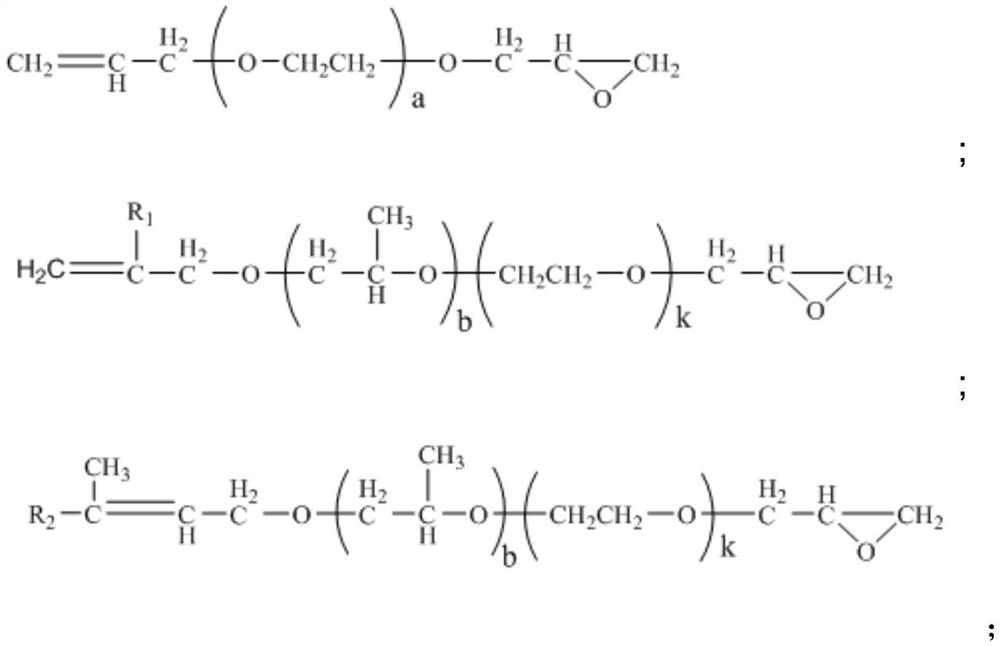

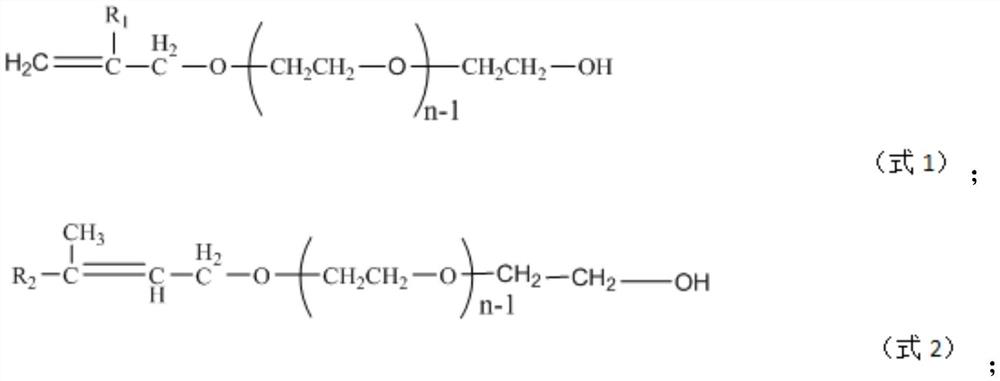

[0035] The above-mentioned (formula 2) component structural formula is:

[0036]

[0037] Wherein, R2 is a C3-C7 linear or branched alkane, and n is an integer of 10-20.

[0038] The structural formula of the above-mentioned (formula 7) component is:

[0039]

[0040] Wherein, R1 is H or CH3, b is an integer of 1-10, and k is an integer of 10-50.

[0041] The synthetic steps of described multipurpose wet rubbing fastness improving agent are as follows:

[0042] S1. Synthesis steps of isocya...

Embodiment 2

[0047] The multi-purpose wet rubbing fastness improving agent obtained in Example 2 includes: 80 parts of isocyanate-terminated prepolymer, 75 parts of (formula 3) structural components, 0.8 parts of organic bismuth, 6 parts of glycerol, 7 parts of acetic acid, ten parts 6 parts of octaalkyltrimethylammonium chloride, 65 parts of structural components (Formula 8), 1.0 part of azodiisobutylamidine hydrochloride, and 70 parts of deionized water.

[0048] The structural formula of the above-mentioned (formula 3) component is:

[0049]

[0050] Wherein, R1 is H or CH3, and n is an integer of 10-20.

[0051] The structural formula of the above-mentioned (Formula 8) component is:

[0052]

[0053] Wherein, R2 is a C3-C7 straight or branched chain alkane, b is an integer of 1-10, and k is an integer of 10-50.

[0054] The synthetic steps of described multipurpose wet rubbing fastness improving agent are as follows:

[0055] S101, the synthesis step of terminal isocyanate pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com