Novel slow-release stabilizer applied to PVC (polyvinyl chloride) hard foamed sheet

A foamed sheet and stabilizer technology, which is applied in the field of PVC rigid foamed sheet stabilizer, can solve the problem of high stability and achieve the effects of strong thermal stability, high cost performance, and slow degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

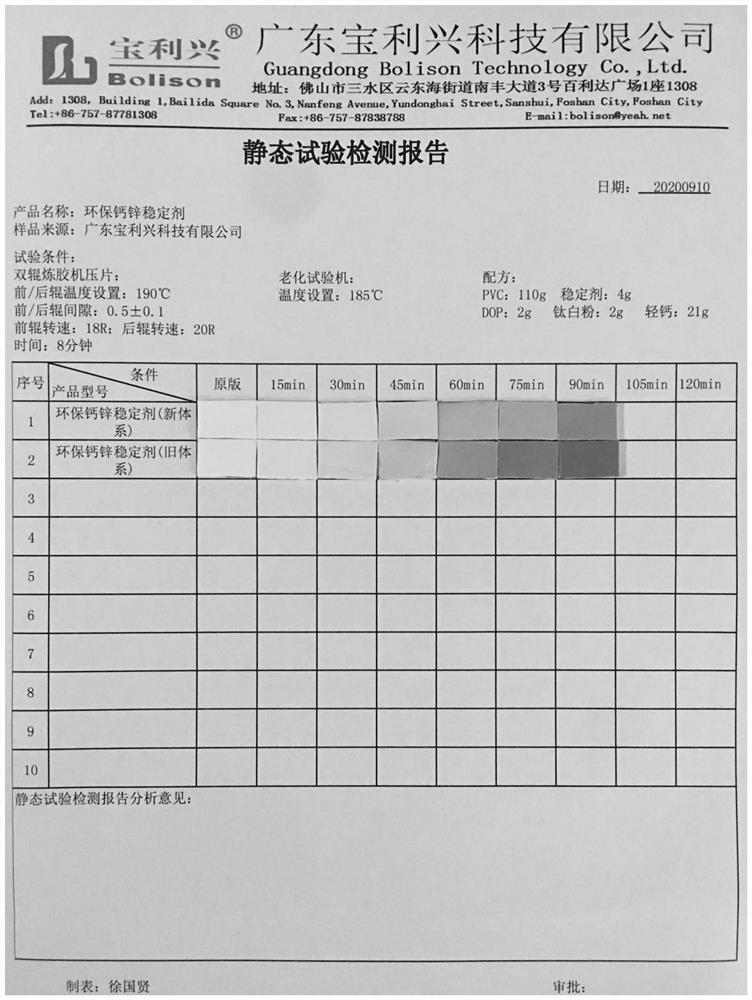

Image

Examples

Embodiment

[0037] A new slow-release stabilizer applied to PVC rigid foamed sheet adopts raw materials comprising the following weight percentages:

[0039] Calcium stearate 5%;

[0040] Syke 10%;

[0041] Uracil 2%;

[0042] Ultrafine 4A zeolite 20%;

[0044] Antioxidant 3%;

[0045] Synergistic heat stabilizer 10%;

[0046] Polyol 5%.

[0047] Prepared by the following steps:

[0048] Step 1. Stir zinc stearate, calcium stearate, Cyclo, uracil and polyhydric alcohol in proportion at 30°C for 15 minutes;

[0049]Step 2, add zeolite and calcium hydroxide and mix and stir for 18 minutes;

[0050] Step 3. Finally, add synergistic stabilizer, antioxidant 1076 and UV-531 ultraviolet absorber, stir for 7 minutes at 75°C under the condition of nitrogen protection, and obtain PVC stabilizer after cooling;

[0051] Step 4, for the PVC stabilizer that obtains in the step 3, adopting outer diameter is 900mm, and inner hole is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com