Worm type central powder feeding type plasma cladding head

A plasma cladding and plasma spray gun technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of powder uniformity and concentration, reduce powder utilization rate, affect cladding quality and other problems, and achieve cladding efficiency. Improve, improve uniformity and convergence, improve the effect of cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

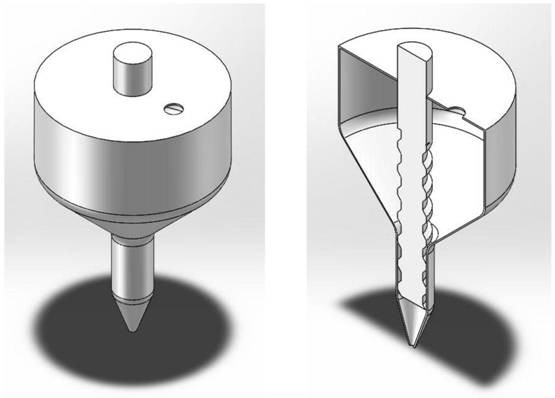

[0015] Different from the traditional pneumatic powder-feeding type cladding head, the present invention belongs to a mechanical central powder-feeding method, and uses a worm to realize the control of the powder-feeding process. In conjunction with above-mentioned accompanying drawing, the specific embodiment of the present invention is as follows:

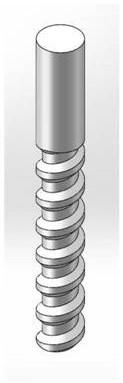

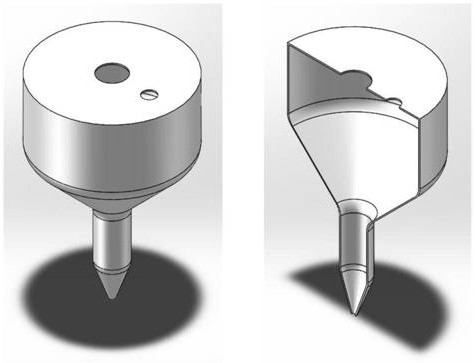

[0016] A worm screw center powder feeding type plasma cladding head is composed of a center powder feeding part, a plasma spray gun part and a water cooling jacket part. The central powder feeding part is composed of powder hopper, powder feeding worm and control system. Powder feeding worm, such as figure 1 As shown, the powder can be fed downward by rotating; the powder hopper, such as figure 2 As shown, the design has a powder inlet, a worm installation port and a powder outlet; the center powder feeding part, such as image 3 As shown, the powder feeding worm is installed on the central shaft, so that the upper end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com