Lightweight honeycomb wave-absorbing material and preparation method thereof

A wave-absorbing material and honeycomb technology, which is applied in shielding materials, electrical components, magnetic field/electric field shielding, etc., can solve the problems of unfavorable camouflage materials such as lightweight requirements, difficulty in improving low-frequency performance, and complicated production processes, so as to facilitate popularization The effect of using, reducing quality and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to the second aspect of the present invention, there is provided a method for preparing a lightweight cellular absorbing material, which is used to prepare the lightweight cellular absorbing material described in the first aspect, comprising the following steps:

[0045] Step 1, using a base material doped with carbon fibers to prepare a honeycomb core, and the honeycomb core is directly used or subjected to subsequent processing;

[0046] Step 2, shaping the honeycomb core dipping glue; the shaping glue includes but not limited to phenolic resin, epoxy resin, etc.;

[0047] Step 3, drying the honeycomb core after dipping and shaping to obtain the honeycomb wave-absorbing material.

Embodiment approach

[0048]In a preferred embodiment of the present invention, the preparation method also includes the following steps:

[0049] Step 4, performing a wave-absorbing performance test on the honeycomb wave-absorbing material obtained in step 1 or step 3, including any one or more of radar wave reflectivity test, transmittance test or electromagnetic parameter test;

[0050] Step 5: Stack the honeycomb cores in the T direction according to the difference in the honeycomb absorbing performance, and then perform multi-layer integral molding to obtain the honeycomb absorbing material.

[0051] In step 1 of the present invention, the substrate includes aramid paper or kraft paper, and the honeycomb core has an aperture side length of 1-10 mm, preferably 2-5 mm.

[0052] The doped carbon fiber is a chopped carbon fiber which is easy to disperse in water, the length of the carbon fiber is 1-10mm, and the mass of the carbon fiber accounts for 0.01%-15% of the total mass of the base material...

Embodiment 1

[0056] A honeycomb wave-absorbing material, the raw material of which is carbon fiber doped with aramid fiber, the prepared honeycomb core has an aperture side length of 2.7mm and a honeycomb core height of 15mm.

[0057] Obtained by the following preparation methods:

[0058] Step 1, using aramid paper doped with chopped carbon fibers to prepare a honeycomb core;

[0059] Step 2, the processed honeycomb core is impregnated with epoxy resin, and then placed for 24 hours;

[0060] In step 3, the honeycomb formed by impregnation is dried in an oven at 80° C. for 4 hours, and then naturally cooled to room temperature to obtain a carbon fiber-doped aramid paper honeycomb absorbing material.

[0061] The carbon fiber length and content (mass fraction) of aramid paper are as follows:

[0062] Carbon fiber length 2mm;

[0063] Carbon fiber content 1.8%.

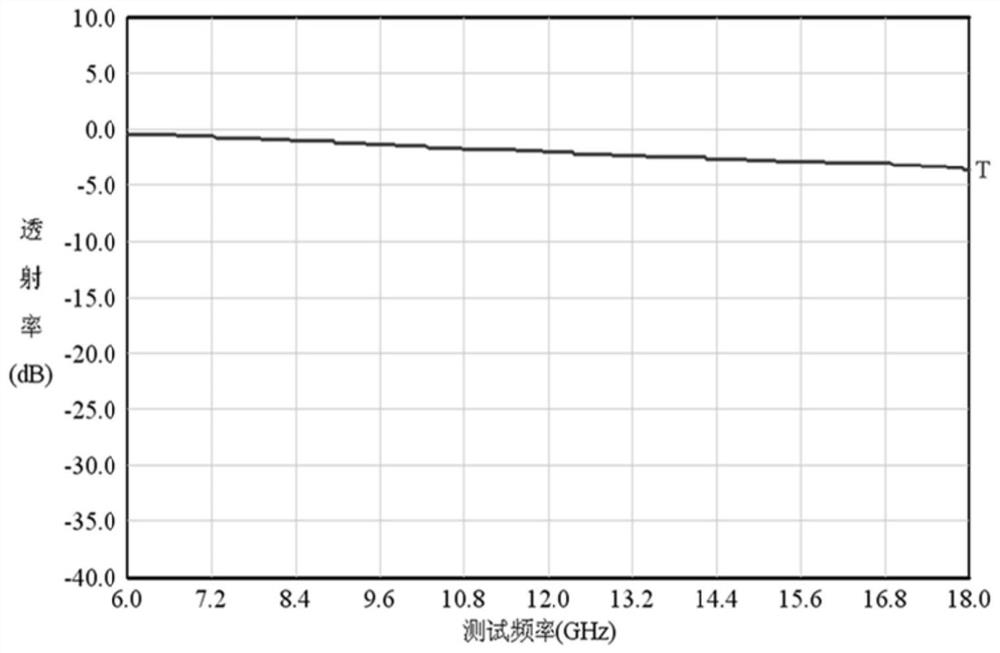

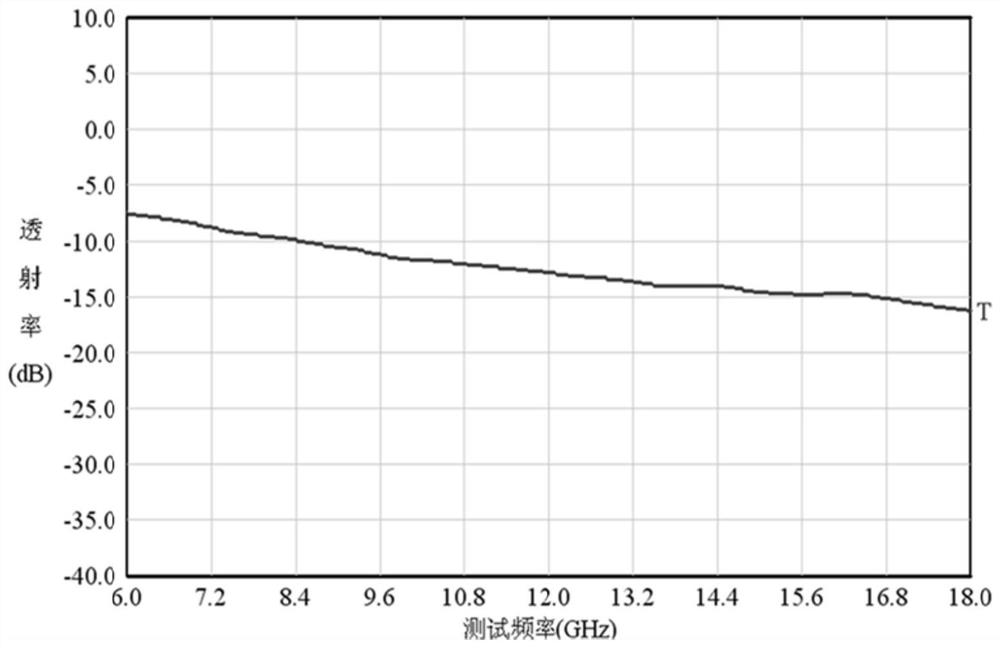

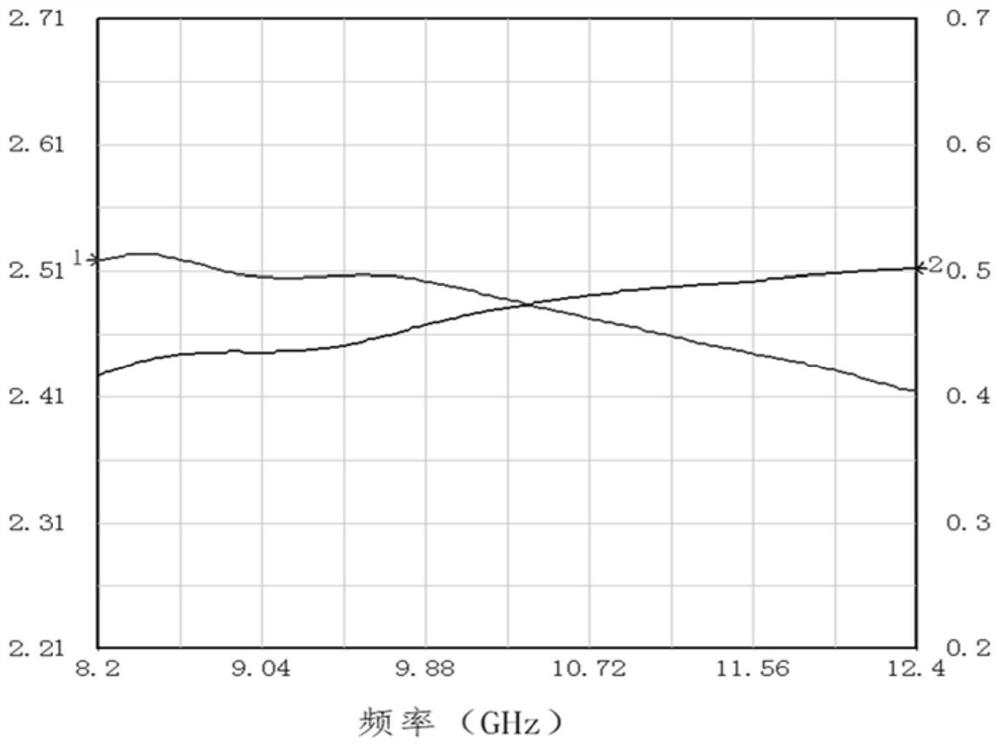

[0064] The transmittance of aramid paper is measured as follows: the test frequency is 6.0~18.0GHz, the average transmittance:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com