Silk protein nerve conduit and preparation method thereof

A nerve conduit, silk protein technology, applied in pharmaceutical formulations, coatings, medical science and other directions, can solve the problems of unstable silk protein solution, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

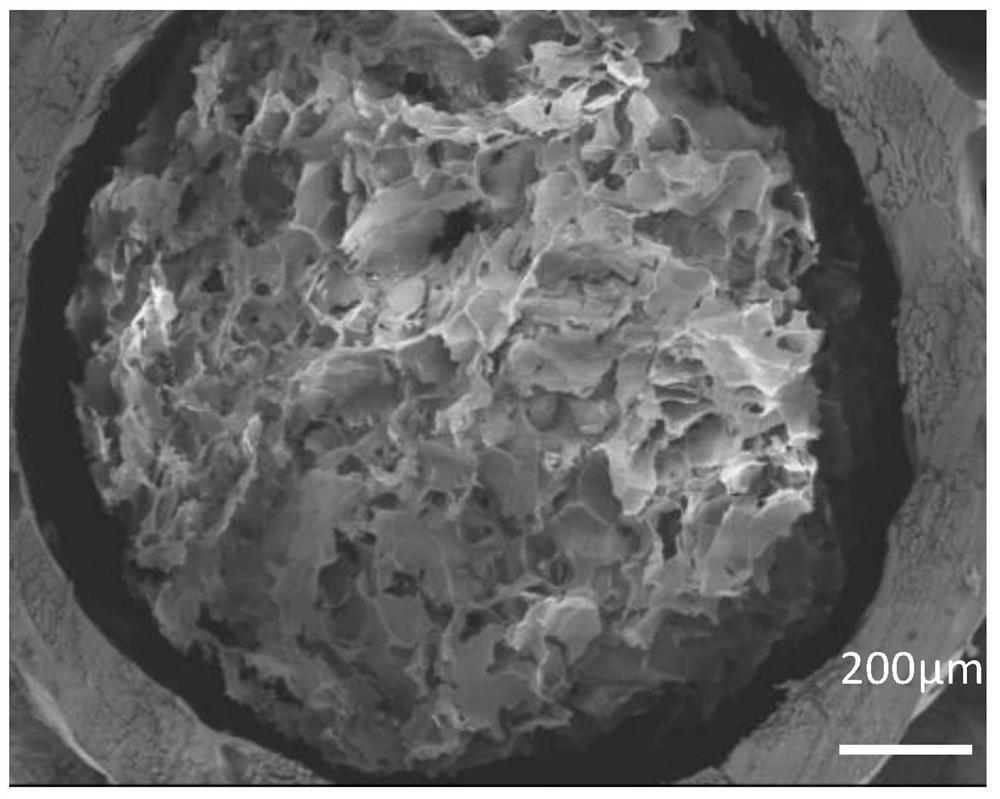

[0036] The present invention also provides a preparation method of the above-mentioned silk protein nerve guide, comprising: S1) braiding silk protein fibers to obtain a catheter matrix; S2) soaking the catheter base in a silk protein solution to obtain a catheter part; S3) The silk protein nanofiber gel with an orientation structure is combined with the conduit part, and after freeze-drying, the silk protein nerve conduit is obtained.

[0037] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

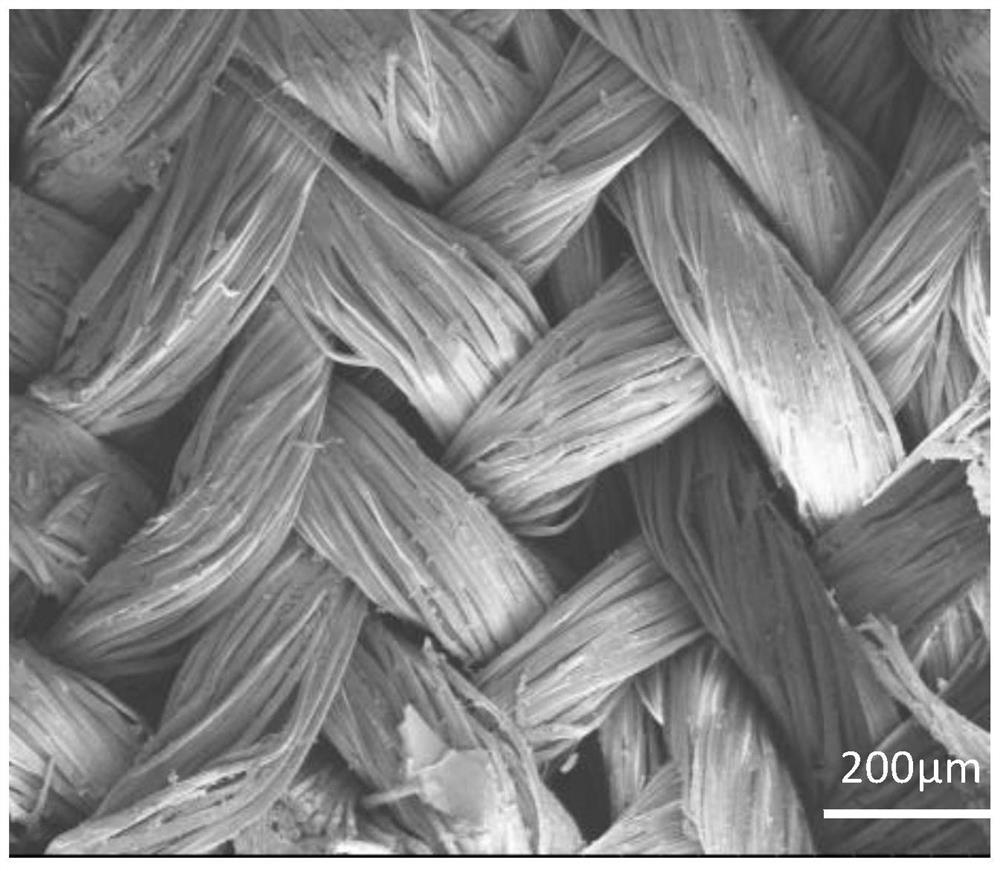

[0038] The catheter matrix is obtained by weaving silk protein fibers; the silk protein fibers are preferably silk, more preferably degummed silk, and more preferably 80-100 denier degummed silk; the braiding angle of the braiding is preferably 45°-60°; The speed of the knitting is preferably 30-60r / min, more preferably 40-50r / min, and more preferably 45r / min; the gear ratio during the knitting is preferably (60-...

Embodiment 1

[0050] (1) Select the smooth first mold with a diameter of 3mm, use a cooked silk thread of 100 denier degummed silk, and weave a skeleton structure on it through a textile machine. The weaving angle is 45°, the speed is 45r / min, and the gear ratio is 80:40 ; The woven skeleton structure is a braided structure.

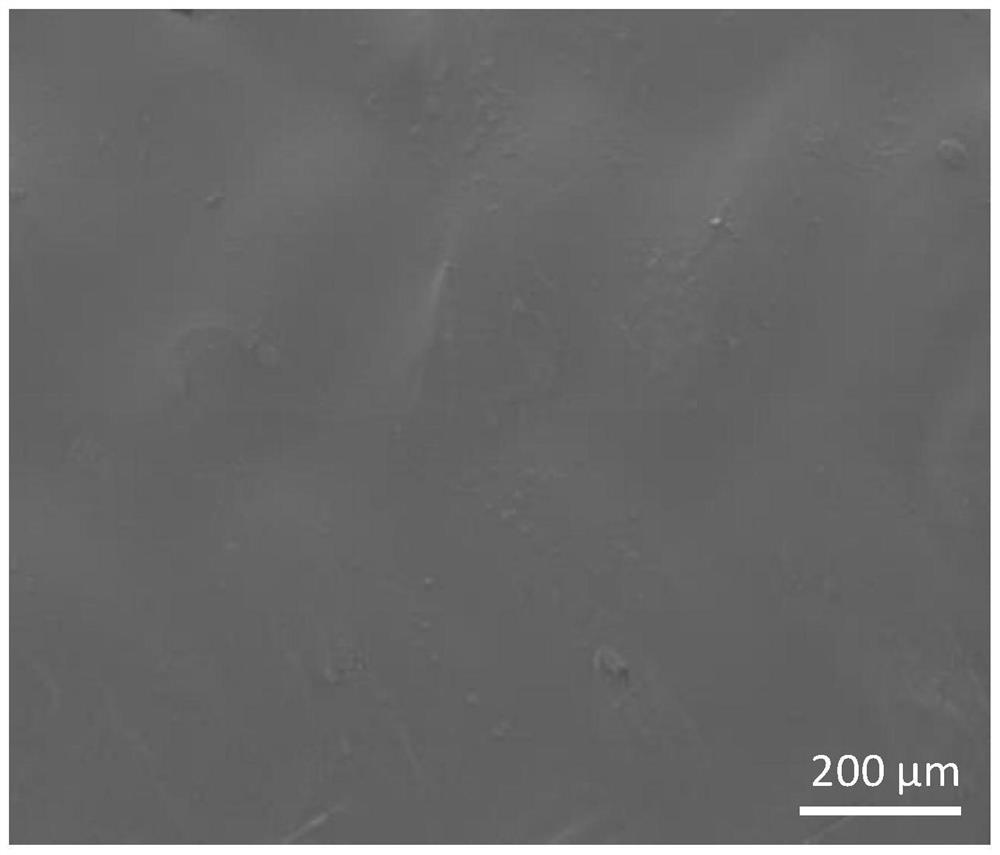

[0051] (2) Submerge the braided catheter completely in 2% silk protein aqueous solution (the content of silk protein nanofibers is 0.8% of the total mass of silk protein), the volume ratio of the catheter to the silk protein aqueous solution is 1:2, at 10°C Under certain conditions, with the slow evaporation of water in the silk protein solution, a layer of insoluble silk fibroin film will be formed on the skeleton, and a silk protein fiber-silk protein film composite catheter will be obtained.

[0052] (3) Prepare 0.2% oriented silk protein nanofiber gel, the basic parameters of electric field induction are: electric field intensity 10V, treatment time 5 minutes. Th...

Embodiment 2

[0056] (1) Select the smooth first mold with a diameter of 5mm, use a cooked silk thread of 100 denier degummed silk, and weave a skeleton structure on it through a textile machine. The weaving angle is 60°, the speed is 45r / min, and the gear ratio is 80:40 ; The woven skeleton structure is a braided structure.

[0057] (2) Submerge the braided catheter completely in 10% silk protein solution (the content of silk protein nanofibers is 4% of the silk protein mass), the volume ratio of the catheter to the silk protein aqueous solution is 1:2, at 90°C Under certain conditions, with the slow evaporation of water in the silk fibroin solution, a layer of insoluble silk fibroin film will be formed on the skeleton, and a silk protein fiber-silk protein film composite catheter will be obtained.

[0058] (3) Place the catheter along a direction parallel to the electrodes and immerse it in 4% silk protein nanofiber gel, then perform electric field treatment on the gel, the electric field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com