Preparation method of lanthanum-modified activated carbon and method for removing fluorine ions in water

A technology for activated carbon and water removal, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of secondary pollution, limited adsorption effect, poor stability of activated alumina, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] This embodiment provides a method for preparing lanthanum-modified activated carbon, including:

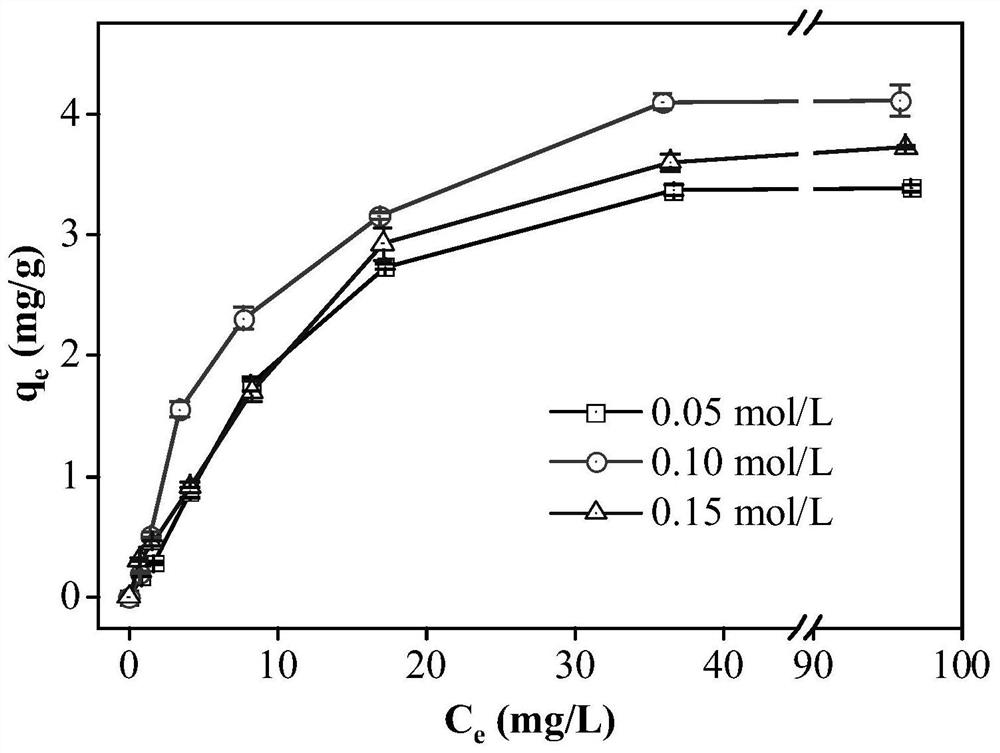

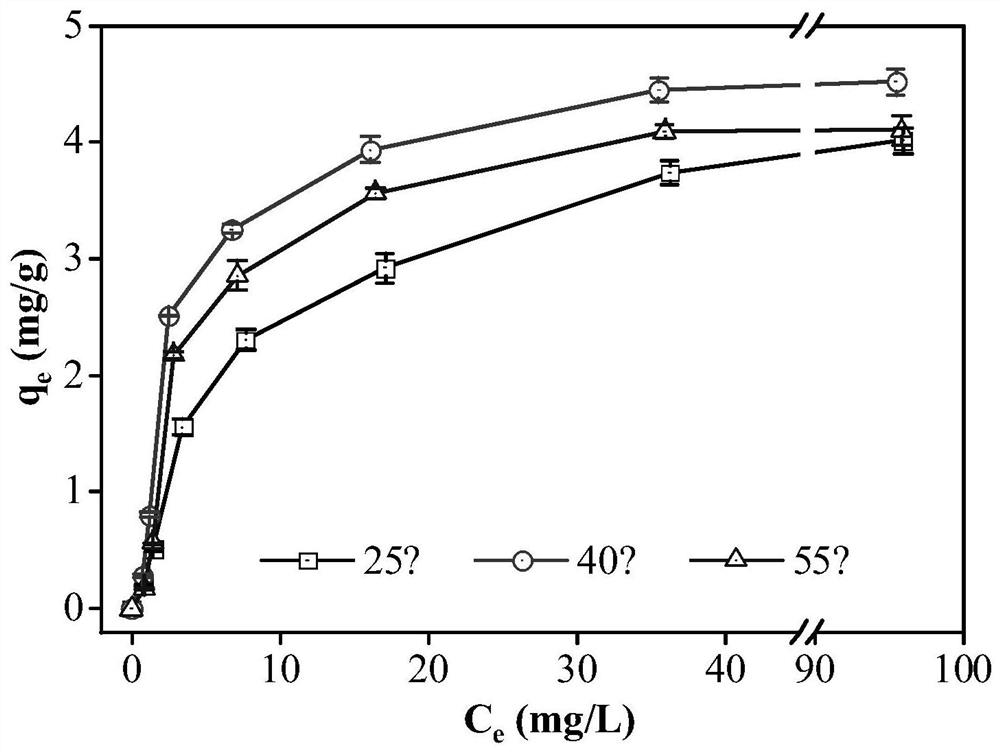

[0026] Immerse activated carbon in a lanthanum salt solution with a concentration of 0.05-0.15 mol / L, adjust the pH value at 4-12, and then react at 25°C-55°C.

[0027] The lanthanum-modified activated carbon prepared by the method can effectively absorb and remove fluorine in water. The surface of activated carbon is rich in oxygen-containing functional groups such as hydroxyl and carboxyl groups, and activated carbon has a large specific surface area and pore volume. By modifying activated carbon with lanthanum, lanthanum can be loaded on the surface of activated carbon. Metal lanthanum can increase the metal cations on the surface of activated carbon and improve the adsorption of anionic pollutants such as fluoride ions. The atomic radius of lanthanum element is large, and it is easy to lose the electrons of s, 5d or 4f' in the outer layer. Lanthanum element has a very ...

Embodiment 1

[0094] Provide a kind of preparation method of lanthanum modified coal-based activated carbon, comprising:

[0095] (1) First, pretreat the activated carbon raw carbon, including grinding and sieving, and screen out activated carbon with a particle size of 400 mesh to 200 mesh (37 to 75 microns), and then wash it with ethanol and ultrapure water until medium Finally, put it in a blast drying oven and dry it at 105°C for 10h.

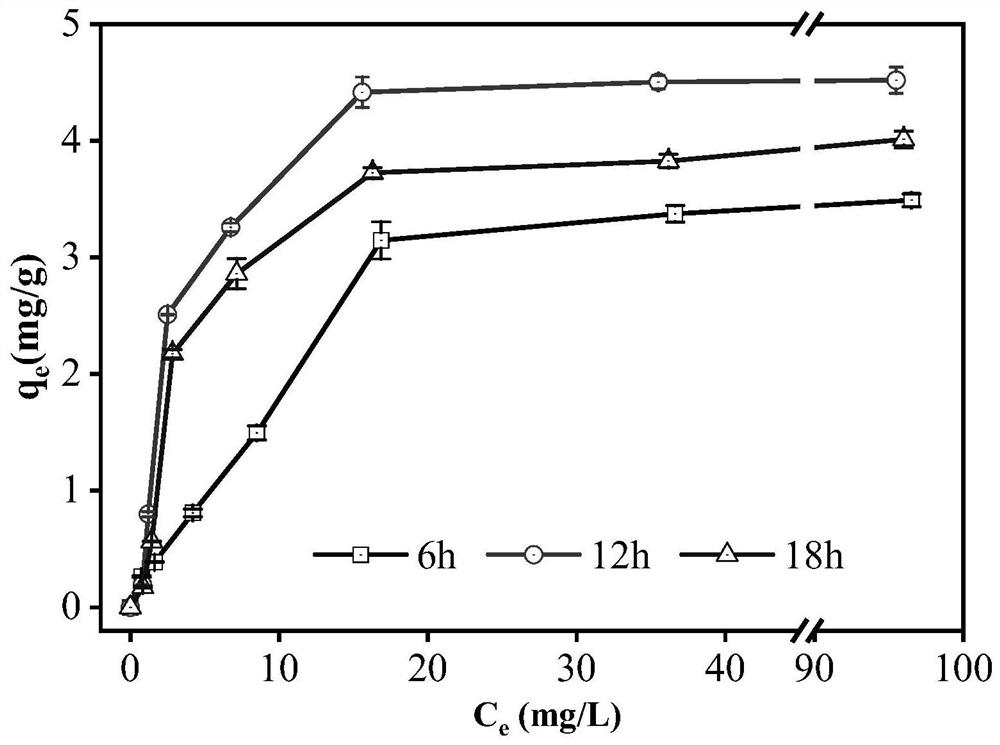

[0096] (2) Get 2.0 g of the pretreated activated carbon obtained in step (1), soak it in the lanthanum nitrate solution of a certain concentration (0.05~0.15mol / L) of 100ml, secondly, at a certain temperature (25 DEG C~55 DEG C) ), adjust the pH to (4-12) by adding 0.001-1.0mol / L NaOH (or HCl) solution dropwise, and react for a certain period of time (6h-18h) at a rotational speed of 400rpm.

[0097] (3) Then cool the mixed solution obtained in step (2) to room temperature, wash off unreacted lanthanum nitrate with alcohol and deionized water and make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com