Flexible overdye coating process for automobile body

A painting process and a technology for automobile bodies, applied to the device for coating liquid on the surface, coating, etc., which can solve the problems of difficult covering in the painting workshop, easy accumulation of paint at the interface of the color separation line, and inability to repair dirty particles, etc. problems, to achieve the effect of improving the overall coating quality, reducing the difficulty of the masking process, and ensuring the appearance quality of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

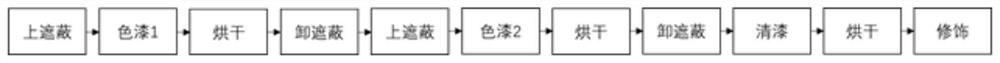

[0048] The present invention is mainly aimed at the two-color scheme of the color separation line at the visible position of the car body. The two-color car body requires higher appearance quality of the color separation line. The process route is as follows:

[0049] 1. Primer → 2. (Middle coat) + color paint → 3. Varnish → 4. Drying → 5. First touch-up → 6. Color masking → 7. Wipe off → 8. Color paint → 9. Clear coat → 10 .Drying → 11. Unmasking → 12. Grinding and polishing the color separation line and wiping → 13. Varnish (color paint off gun) → 14. Drying → 15. Checking and retouching.

Embodiment 2

[0051] A flexible color registration coating process for automobile body, the specific steps are as follows:

[0052] 1. Primer: The traditional process is pretreatment, electrophoresis, electrophoresis drying, electrophoresis inspection and modification, primer, PVC, intermediate coating, intermediate coating drying, intermediate coating inspection and modification; the intermediate coating-free process is pretreatment, electrophoresis , electrophoresis drying, primer, PVC, glue drying, primer inspection and modification and other processes.

[0053] 2. Color paint: light color paint spraying, the temperature of the spray booth is (23±2)°C, the humidity of the spray booth is (65±5)%, the wind speed of the spray booth is (0.3±0.05) m / s, and the cleanliness of the spray booth requires a diameter of (5 ~ 10) μm dust < 10, color paint material viscosity standard within ± 0.5s, wet film solid content after pre-drying, the inner surface ≥ 85%, the outer surface ≥ 90%, light-colored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com