Circulating type high-heat-preservation concrete block and preparation method thereof

A concrete block, high thermal insulation technology, applied in building components, buildings, building structures, etc., can solve the problems of difficult construction of thermal insulation layers, insufficient thermal insulation capacity, short service life, etc., and achieve high strength, long service life, Solve the effect of insufficient heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

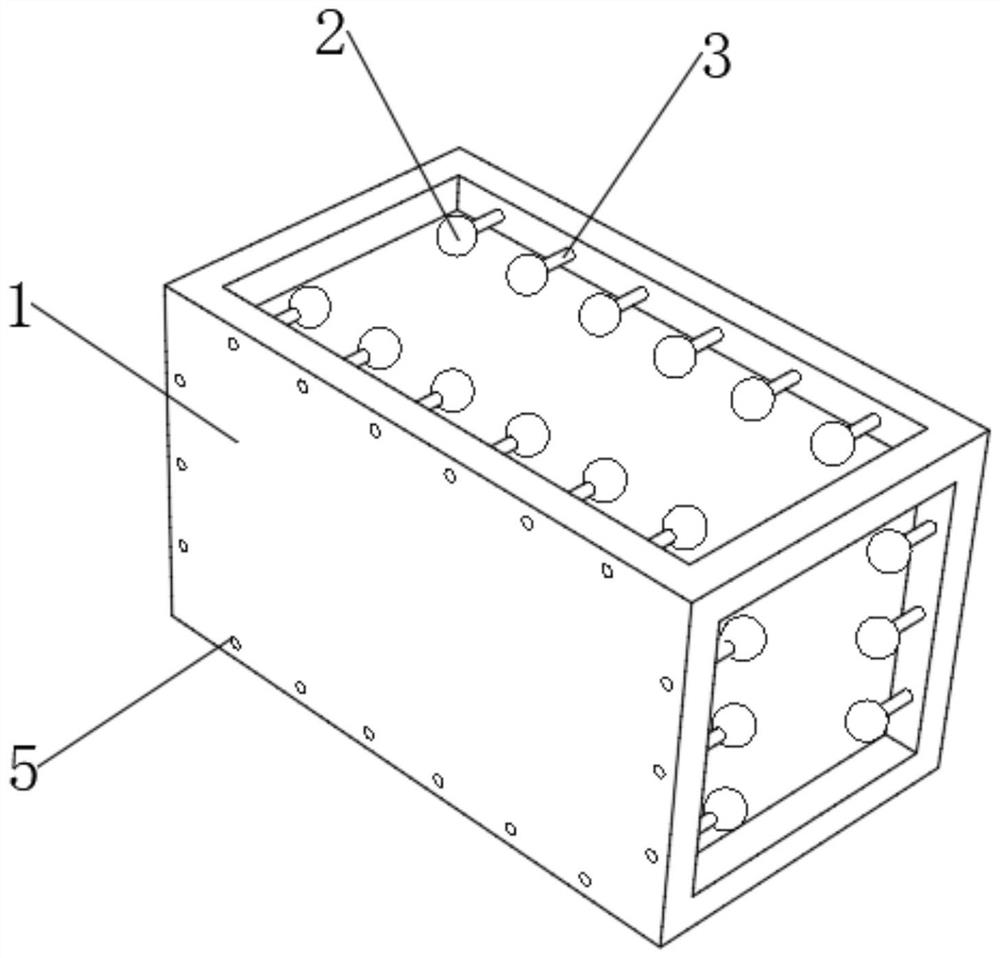

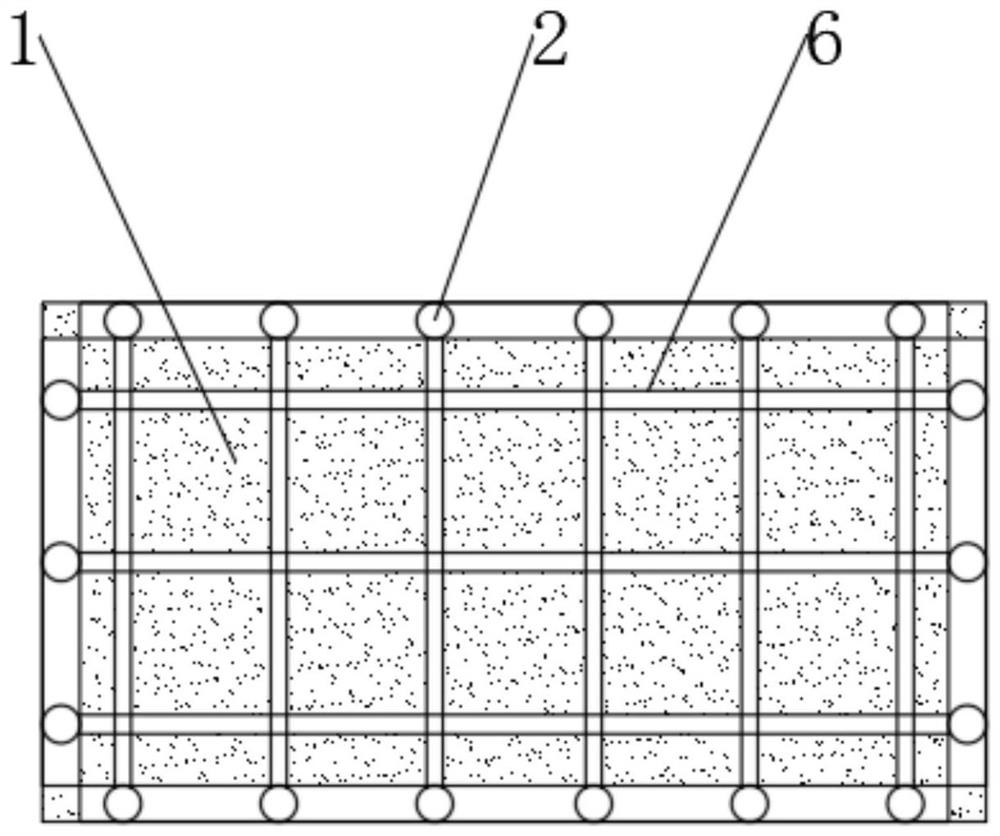

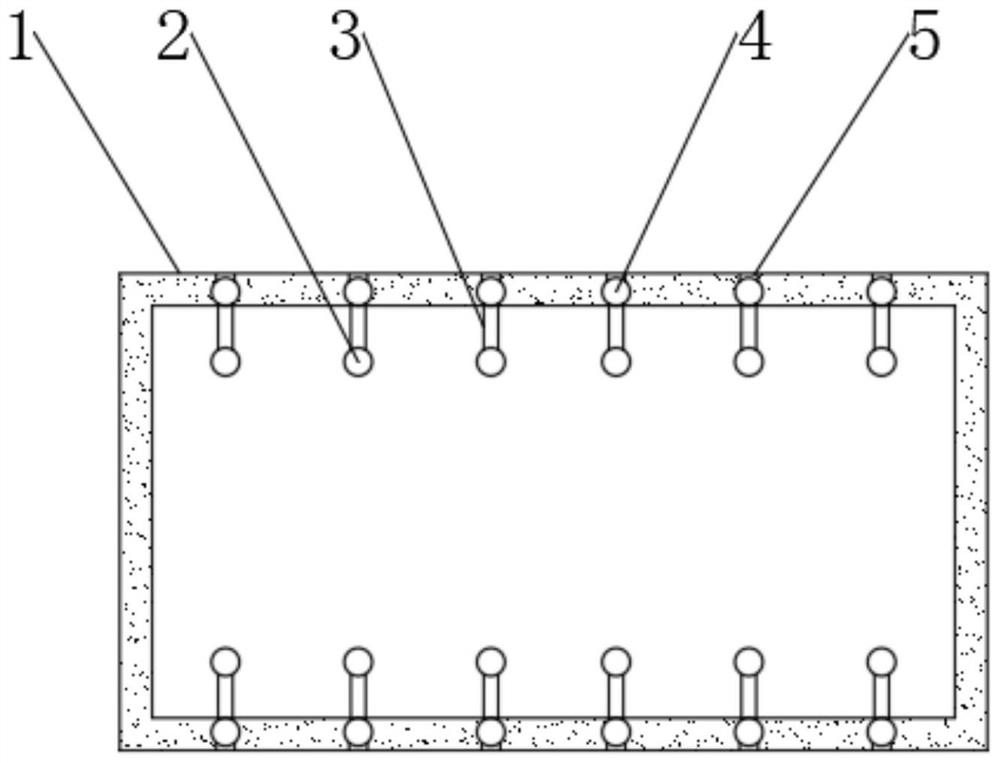

[0046] see figure 1 , a circulating high thermal insulation concrete block, including a block body 1 and a plurality of circulating thermal insulation components, the upper and lower ends of the block body 1 and the left and right ends are provided with mortar pre-filled grooves, and the circulating thermal insulation components are partially installed in In the mortar pre-filled groove, the block body 1 includes the following raw materials in parts by weight: 80 parts of cement, 50 parts of gypsum, 15 parts of fly ash, 40 parts of vitrified microspheres, 2 parts of polyacrylamide, 2 parts of polyvinyl alcohol 0.5 parts of wood fiber, 2 parts of water reducer, 2 parts of expanded perlite powder, 0.1 part of triethanolamine, 0.1 part of sodium sulfate, and 15 parts of sand.

[0047] see Figure 2-3 , the circulating thermal insulation components include inner heat-absorbing ball 2, heat-connecting rod 3, outer heat-absorbing ball 4, heat-radiating block 5 and heat-absorbing wi...

Embodiment 2

[0062] see figure 1 , a circulating high thermal insulation concrete block, including a block body 1 and a plurality of circulating thermal insulation components, the upper and lower ends of the block body 1 and the left and right ends are provided with mortar pre-filled grooves, and the circulating thermal insulation components are partially installed in In the mortar pre-filled groove, the block body 1 includes the following raw materials in parts by weight: 90 parts of cement, 65 parts of gypsum, 20 parts of fly ash, 50 parts of vitrified microspheres, 3 parts of polyacrylamide, 3 parts of polyvinyl alcohol 2 parts, wood fiber 2 parts, water reducer 3 parts, expanded perlite powder 3 parts, triethanolamine 2 parts, sodium sulfate 3 parts, sand 30 parts.

[0063] A method for preparing a circulating high thermal insulation concrete block, comprising the following steps:

[0064] S1. Process the block mold in advance, and apply a release agent in the cavity of the block mold...

Embodiment 3

[0071] see figure 1 , a circulating high thermal insulation concrete block, including a block body 1 and a plurality of circulating thermal insulation components, the upper and lower ends of the block body 1 and the left and right ends are provided with mortar pre-filled grooves, and the circulating thermal insulation components are partially installed in In the mortar pre-filled groove, the block body 1 includes the following raw materials in parts by weight: 100 parts of cement, 80 parts of gypsum, 30 parts of fly ash, 60 parts of vitrified microbeads, 5 parts of polyacrylamide, and 5 parts of polyvinyl alcohol 3 parts of wood fiber, 5 parts of water reducer, 5 parts of expanded perlite powder, 4 parts of triethanolamine, 5 parts of sodium sulfate, 40 parts of sand.

[0072] A method for preparing a circulating high thermal insulation concrete block, comprising the following steps:

[0073] S1. Process the block mold in advance, and apply a release agent in the cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com