A kind of yttrium nickel alloy and its preparation method and application

A technology of yttrium-nickel alloy and liquid alloy is applied in the field of yttrium-nickel alloy and its preparation, and can solve the problems of affecting product consistency, large fluctuation of rare earth content in rare earth alloy, and high labor intensity of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

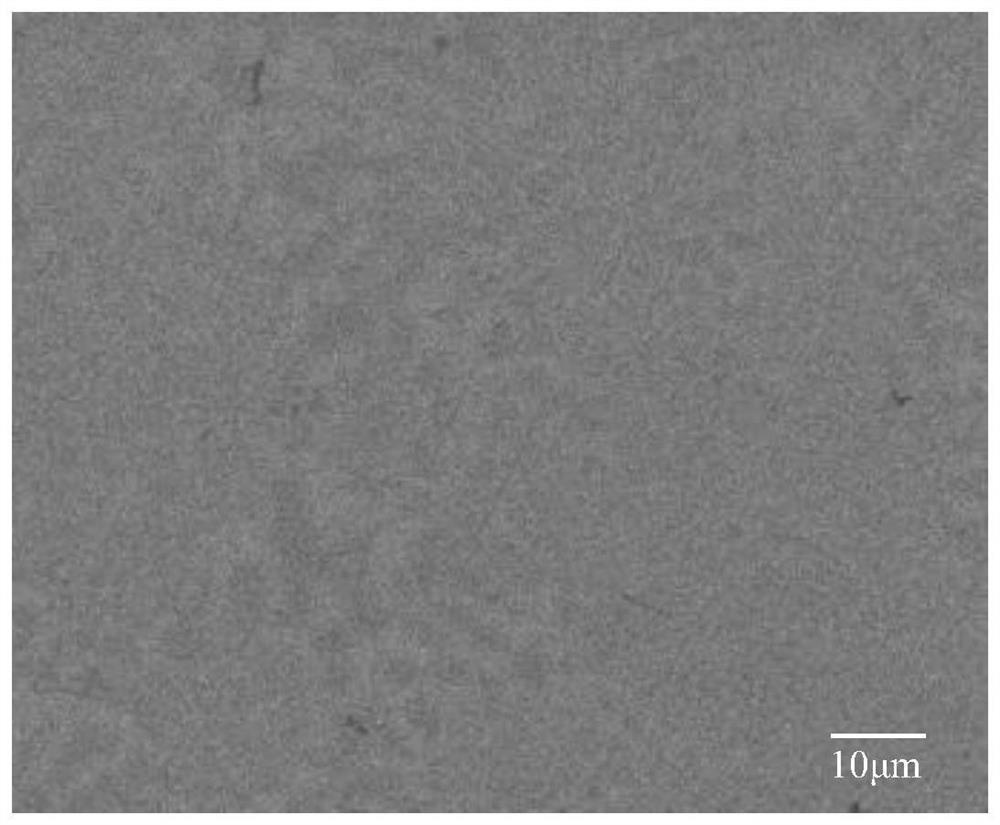

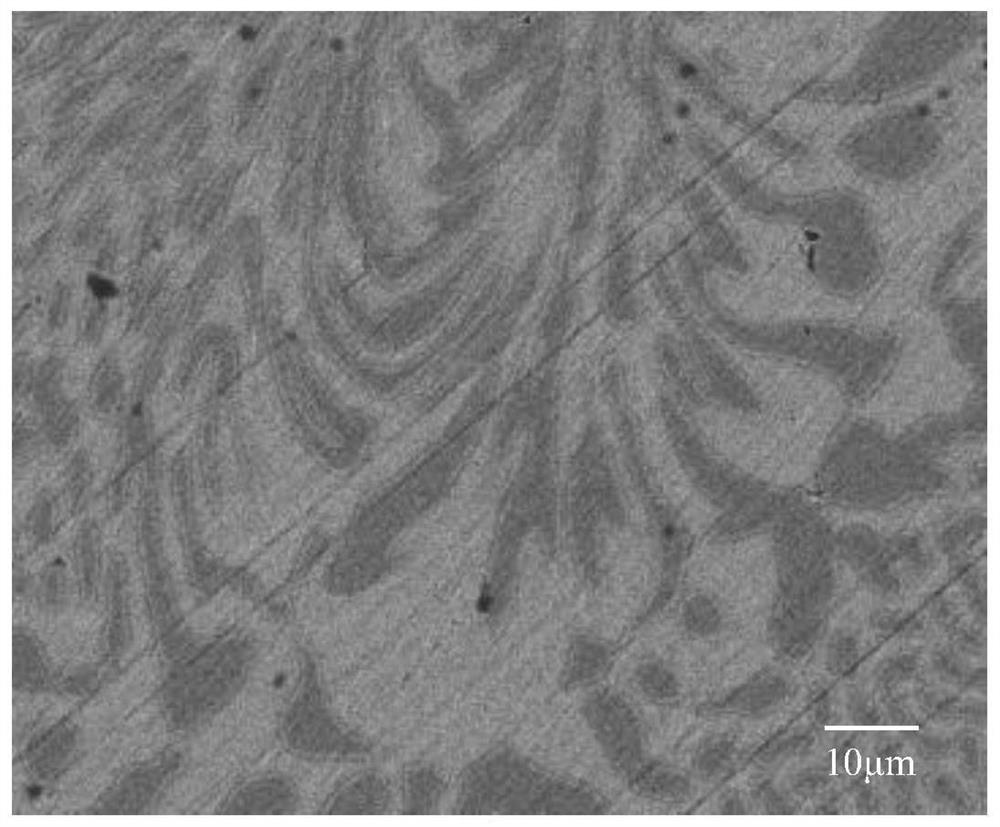

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of yttrium nickel alloy, comprises the following steps:

[0027] A molten salt electrolyte is provided, the molten salt electrolyte includes YF 3 and LiF;

[0028] Provide electrolytic raw materials, the electrolytic raw materials include Y 2 o 3 and NiO;

[0029] placing the molten salt electrolyte in an electrolytic cell, and heating until the molten salt electrolyte is completely melted to obtain an electrolyte melt;

[0030] Add electrolytic raw materials to the electrolyte melt, place the receiving crucible in the electrolytic cell, use the graphite plate as the anode, and use the inert metal electrode as the cathode to conduct electrolysis, form a liquid alloy on the surface of the cathode, and collect it in the receiving in the crucible;

[0031] The collected liquid alloy is cast to obtain yttrium-nickel alloy.

[0032] The present invention provides a molten salt electrolyte, the molten salt electrolyte ...

Embodiment 1

[0050] Will YF 3 and LiF are mixed in a mass ratio of 86:14 to obtain a molten salt electrolyte; the Y 2 o 3 Mixed with NiO in a mass ratio of 55:45 to obtain electrolytic raw materials;

[0051] Place the graphite plate in a circular graphite electrolytic cell, place the molten salt electrolyte in the electrolytic cell, heat to completely melt the molten salt electrolyte to obtain an electrolyte melt; continue heating to 1012°C, insert the molybdenum rod into the In the electrolyte melt, a molybdenum crucible is placed on the bottom of the electrolytic cell, and then electrolytic raw materials are added to the electrolytic cell, and the graphite plate is used as an anode and the molybdenum rod is used as a cathode, and direct current is used for electrolysis; the electrolysis During the process, the electrolytic raw materials are continuously added to the electrolytic cell, and YF is replenished in time according to the electrolysis situation. 3 and LiF, so that the distri...

Embodiment 2

[0058] Will YF 3 、BaF 2 and LiF are mixed in a mass ratio of 87:4:9 to obtain a molten salt electrolyte; the Y 2 o 3 Mixed with NiO in a mass ratio of 46:54 to obtain electrolytic raw materials;

[0059] Place the graphite plate in a circular graphite electrolytic cell, place the molten salt electrolyte in the electrolytic cell, heat to completely melt the molten salt electrolyte to obtain an electrolyte melt; continue heating to 980°C, insert a tungsten rod into the In the electrolyte melt, place the molybdenum crucible at the bottom of the electrolytic cell, then add electrolytic raw materials into the electrolytic cell, use the graphite plate as the anode and the tungsten rod as the cathode, and conduct electrolysis with direct current; during the electrolysis process , the electrolytic raw materials are continuously added to the electrolytic cell, and YF is replenished in time according to the electrolytic situation 3 、BaF 2 and LiF, so that the distribution ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com