Macropore macadam epoxy grouting repair structure for epoxy asphalt steel bridge deck

A technology of epoxy asphalt and epoxy grouting, which is applied in bridge maintenance, epoxy resin glue, application, etc., can solve the problem of water tightness at the joints of old and new pavements in waterproof performance, and the durability of new pavement is difficult to meet the domestic use requirements. Unable to meet the requirements of use, the general effect and other problems, to achieve the effect of rapid opening of traffic, simple structure, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

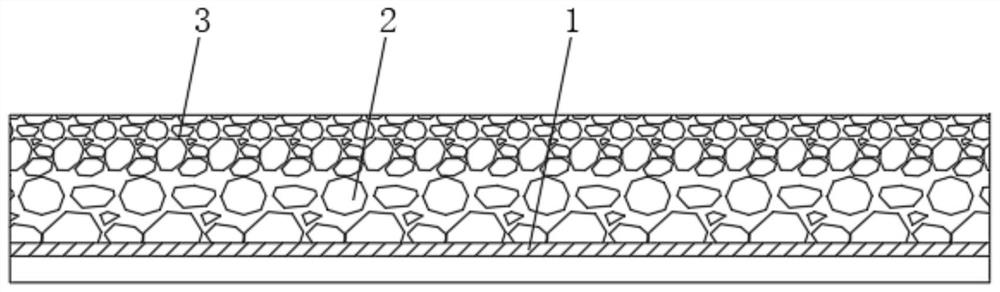

[0024] An epoxy asphalt steel bridge deck with macroporous gravel epoxy grout repair structure, such as figure 1 As shown, it includes a waterproof adhesive layer 1, an asphalt normal temperature large-pore gravel layer 2 and an epoxy resin permeable layer 3. The waterproof adhesive layer 1 is arranged on the inner surface of the pit on the steel bridge deck, and the asphalt normal temperature large-pore 2 is arranged inside the pit on the steel bridge deck, and the epoxy resin permeable layer 3 is evenly coated on the upper end surface of the asphalt normal temperature large-pore gravel layer 2, so that part of the uppermost gravel surface of the large-pore gravel layer is exposed.

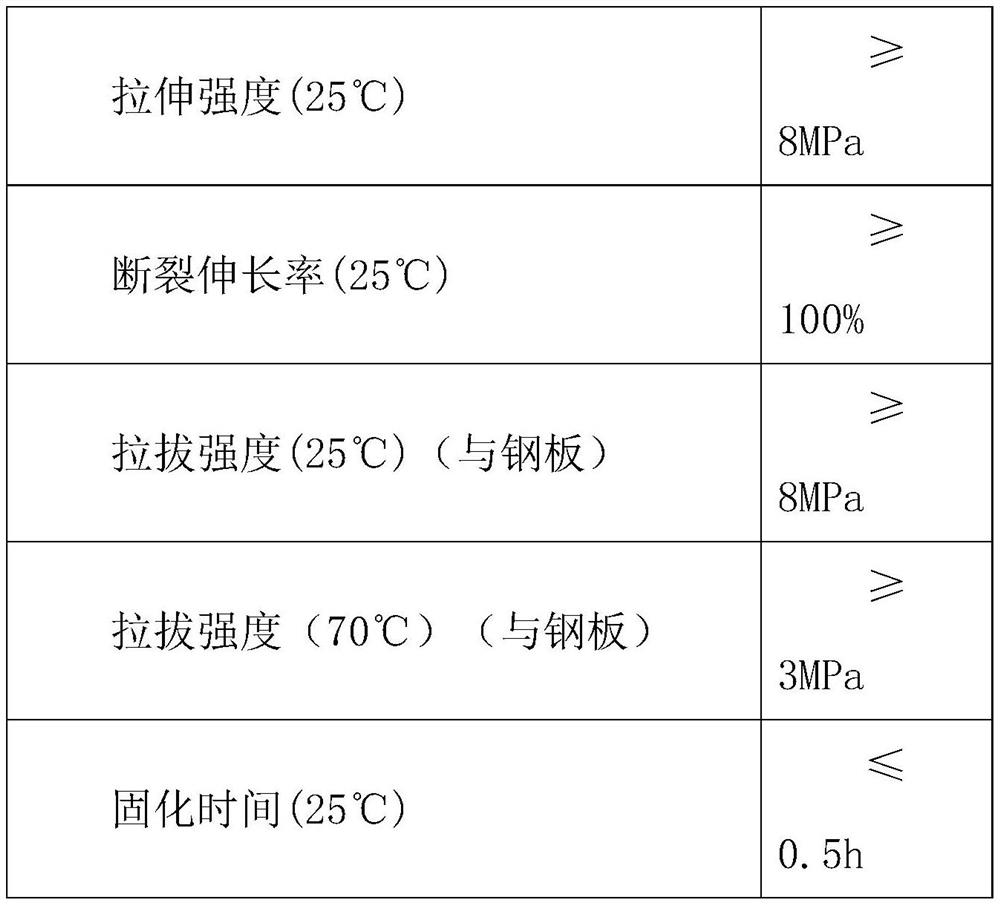

[0025] The amount of waterproof adhesive layer 1 is 0.6-0.8kg / ㎡, and the waterproof adhesive layer 1 is a mixture of epoxy resin, curing agent and accelerator. The mass ratio of epoxy resin, curing agent and accelerator is 1-1.5: 0.1-0.5: 0.001.

[0026] The epoxy resin adopts bisphenol A epoxy ...

Embodiment 2

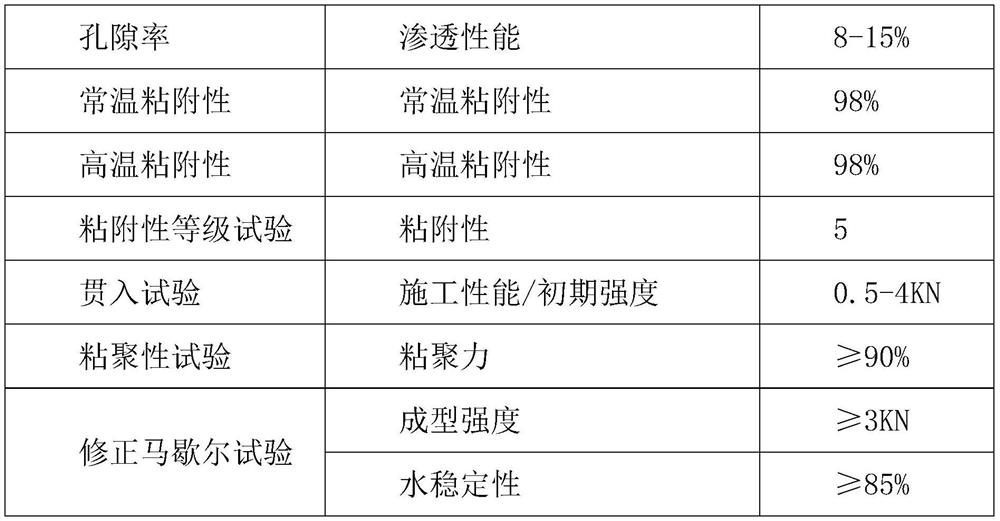

[0043] Take normal temperature liquid asphalt (70# road petroleum asphalt, 0# diesel oil and interface agent LF-2, the ratio is 7:2:1), and a certain grade of gravel, and mix them at room temperature according to the ratio of asphalt to asphalt 5:100, and mix well Finally, high-performance asphalt and large-pore gravel are formed at room temperature. Packing in bags for later use, this step is prefabricated in advance.

[0044]Take epoxy resin, curing agent and accelerator (E-51 bisphenol A epoxy resin, 651 low molecular weight polyamide and DMP-30), mix and stir according to 1:0.3:0.001, after stirring evenly, spread it on the pit For the bottom of the tank and the four walls of the pit, the dosage is controlled at 0.6-0.8kg / ㎡ to form a waterproof adhesive layer 1 .

[0045] Then, pave high-performance asphalt room temperature large-pore gravel on the waterproof adhesive layer 1, compact and level it with manual compaction or small vibratory plate compaction, after compactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com