Method for testing humidity and heat resistance reliability of solar cell

A technology of solar cells and solar cells, which is applied in the fields of climate sustainability, semiconductor/solid-state device testing/measurement, circuits, etc. It can solve the problems of long DH test time, unfavorable rapid optimization of battery performance, slow feedback of reliability and quality, etc. problems, achieve fast and effective reliability and stability, save test time and component manufacturing costs, and improve efficiency and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

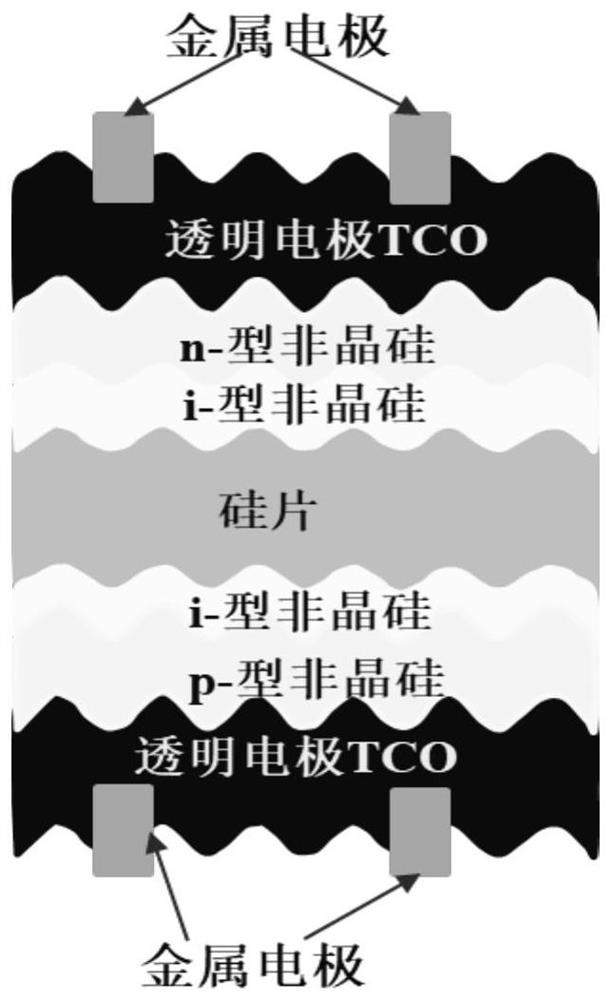

[0022] Taking silicon heterojunction (SHJ) solar cells as an example, the SHJ solar cells are prepared first, and the process flow is: raw silicon wafer → cleaning and texturing → CVD preparation of amorphous silicon films (including intrinsic amorphous silicon, N-type amorphous silicon, etc.) Silicon, P-type amorphous silicon), forming PN junction and NN + High and low junction → production of transparent conductive oxide film (TCO for short) → metallization technology to form electrodes → electrical performance testing and sorting → packaging and storage. Silicon heterojunction (SHJ) solar cell structure such as figure 1 shown.

[0023] From the above SHJ solar cell process flow, it can be found that the parts that affect the reliability of solar cells and components include: silicon wafer quality, amorphous silicon film structure and defect characteristics, TCO material composition and structure, metal electrodes, etc.

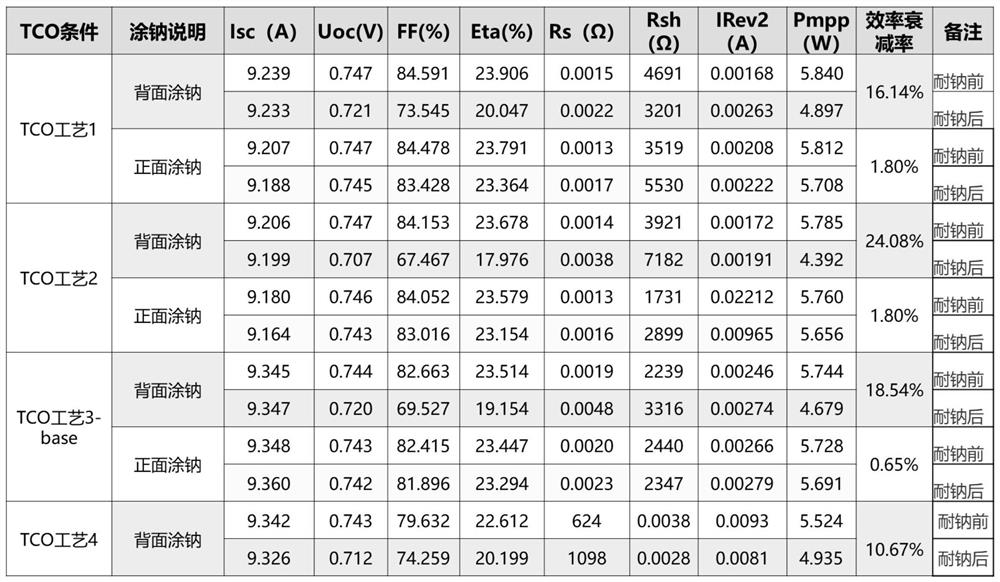

[0024] In this embodiment, the impact of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com