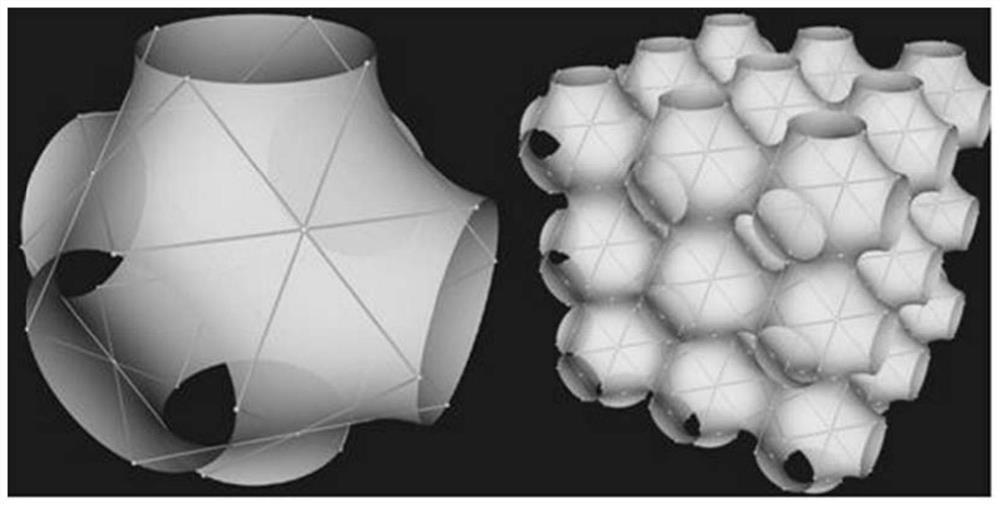

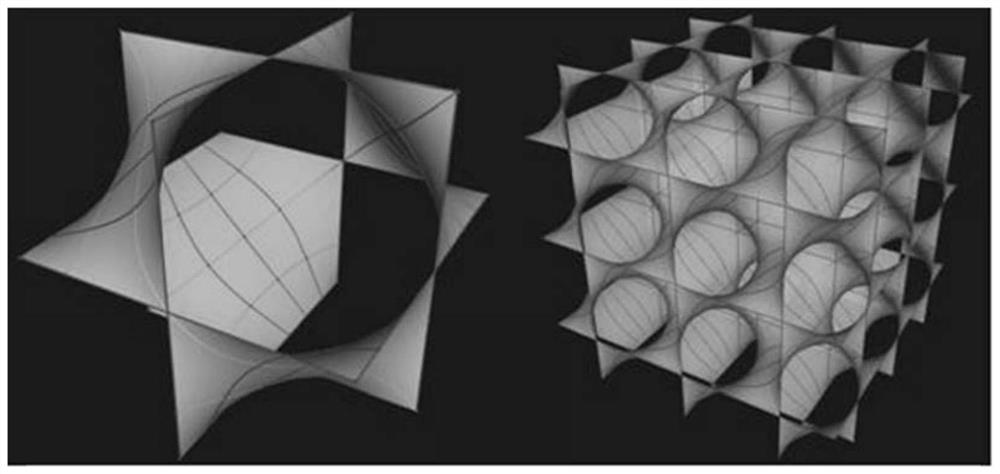

Bionic 3D printing aerogel thermal insulation board and preparation method thereof

A technology of thermal insulation board and 3D printing, which is used in thermal insulation, additive processing, climate change adaptation, etc. It can solve the problems of thermal insulation performance and unsatisfactory bulk density of thermal insulation board, and achieve the optimization of lightweight thermal insulation performance, reduction of heat loss, The effect of fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

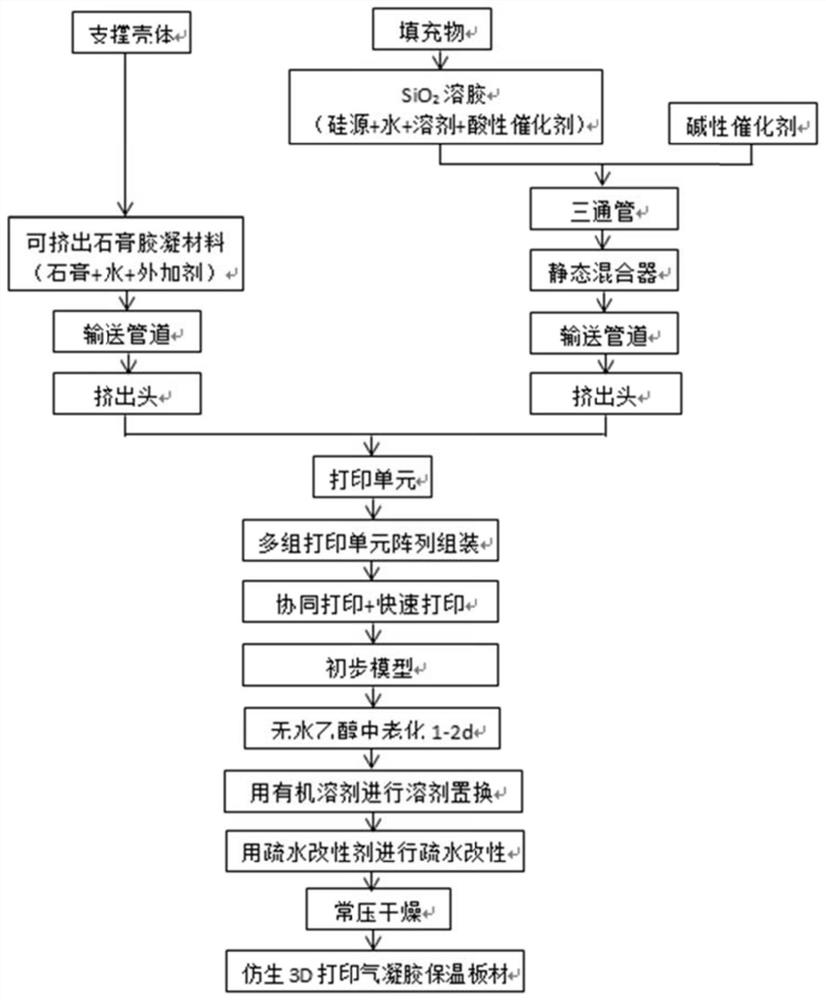

[0046] A method for manufacturing bionic 3D printed airgel insulation boards, the preparation flow chart is as follows image 3 shown, including the following steps:

[0047] (1) Weigh 20.83g tetraethyl orthosilicate, 46.07g ethanol and 18.02g deionized water (the molar ratio of tetraethyl orthosilicate to ethanol and ionized water is 1:10:10), add 1.0415g polydimethyl Siloxane (mass ratio of ethyl orthosilicate to polydimethylsiloxane: 1:0.05), use 10% dilute hydrochloric acid to adjust the pH value of the system to 2, hydrolyze at 25°C for 24h to obtain SiO 2 Colloidal solution;

[0048] (2) The molar ratio of ammonia water to tetraethyl orthosilicate is 0.003:1, and the ammonia water is diluted to SiO 2 equal volume of colloidal solution, the SiO 2 The colloidal solution and dilute ammonia water are transported to the three-way pipe through two hoses through a peristaltic pump and mixed to obtain SiO 2 Precursor sol, the pH value of the mixed system is 6.3, SiO 2 The g...

Embodiment 2

[0055] A method for manufacturing bionic 3D printed airgel insulation panels, comprising the following steps:

[0056] (1) Weigh 20.83g tetraethyl orthosilicate, 23.04g ethanol and 27.03g deionized water (the molar ratio of tetraethyl orthosilicate to ethanol and ionized water is 1:5:15), add 0.8332g polydimethyl Siloxane (mass ratio of ethyl orthosilicate to polydimethylsiloxane 1:0.04), adjust the pH of the system to 2 with 10% dilute hydrochloric acid, and hydrolyze it at 25°C for 24h to obtain SiO 2 Colloidal solution;

[0057] (2) The molar ratio of ammonia water to tetraethyl orthosilicate is 4×10 -3 , dilute ammonia to SiO 2 Equal volume of colloidal solution, SiO 2 The colloidal solution and dilute ammonia water are transported to the three-way pipe through two hoses through a peristaltic pump and mixed to obtain SiO 2 Precursor sol, the pH value of the mixed system is 6.6, SiO 2 The gel time of the precursor sol is 10-15min;

[0058] (3) Prepare the supporting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com